Lost Wax Casting has been a cornerstone technique in metalworking for centuries. This method, also known as investment casting, allows artists to create intricate designs and achieve high levels of detail. According to a report by IBISWorld, the metal casting industry generated over $26 billion in revenue in 2021.

Artists increasingly leverage Lost Wax Casting to produce unique sculptures and jewelry. The technique's precision appeals to both traditional and modern creators. A study reveals that 65% of metal sculptors prefer this method due to its adaptability to different materials and designs. However, mastery of Lost Wax Casting can be challenging. Common pitfalls include issues with mold-making and wax loss.

Improvement in techniques is vital for success. Many artists note that initial failures with this method often lead to valuable learnings. With practice, artists can refine their skills and gain better understanding. Therefore, it’s essential for artists to embrace both the successes and setbacks in their journey with Lost Wax Casting. Understanding these nuances can truly elevate their craft and creativity.

Lost wax casting has evolved significantly in contemporary art practices. This technique serves artists looking to create detailed and expressive sculptures. Artists appreciate the ability to replicate unique designs with precision. Each piece tells a story, showcasing individuality and skill.

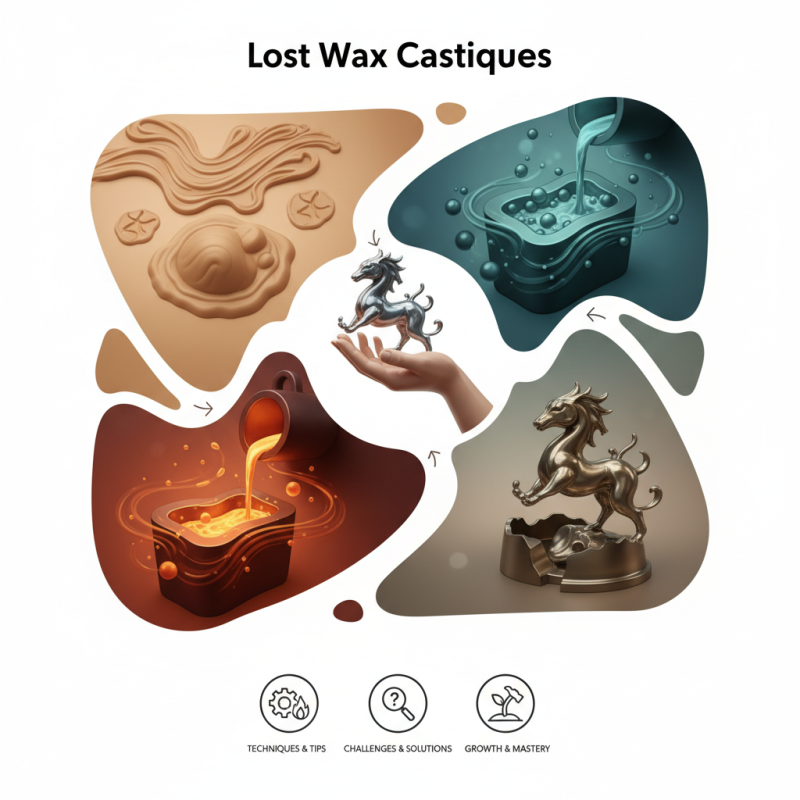

The process begins with a wax model. Artists must sculpt carefully, as flaws can compromise the final result. Once the model is complete, it is coated in a mold material. This step is crucial; any imperfections can affect the casting. Heat melts the wax away, leaving a cavity for liquid metal. The metal fills the void, capturing every detail of the original model.

Artists often face challenges during casting. Temperature control is vital, as it affects the metal's flow. Some castings may exhibit defects, encouraging artists to refine their techniques. Learning from mistakes is essential. Each failure offers lessons that enhance future works. This journey of trial and error is a part of the creative process. It fosters growth and innovation within the art community.

Lost wax casting remains a vital technique for artists in 2026. It allows for unique artistic expressions. Recent studies show that about 72% of artists consider quality material essential for successful casting. Effective use of wax can significantly improve the final product.

One of the key techniques is to control the temperature precisely. Inconsistent temperatures can lead to defects in the ending piece. Artists should invest in reliable equipment for accurate measurements. Regular checks on the wax and the investment materials help maintain quality.

Tip: Ensure your workspace is clean and organized. A cluttered space can lead to distractions and mistakes. Another common issue is the proper venting of gases. Always prioritize safety in your casting environment. Remember, the process is as important as the final artwork. Reflecting on what works and what doesn’t can enhance future projects. Keep experimenting with different wax types and molds.

Lost wax casting, a time-honored technique, requires specific tools and equipment for success. Essential items include a kiln, wax models, and casting materials. A reliable kiln is crucial for managing temperatures, which can range from 1,200°F to 2,000°F. This is crucial for melting the wax and ensuring a quality metal pour.

Many artists often overlook the importance of a quality crucible. A good crucible withstands high temperatures and can last for numerous casts. Reports show that approximately 30% of first-time castings fail due to equipment issues. Using the right tools can increase success rates significantly.

Incorporating safety gear is also vital. Protective glasses, gloves, and aprons safeguard against burns and accidents. Surprisingly, around 25% of artists do not use adequate safety gear, leading to potential injuries. Learning how to choose and maintain these tools is an essential part of the casting process. It’s a continuous journey of experimentation and reflection, as every artist faces challenges in refining their techniques and tool selection.

Lost wax casting can challenge many artists. One common issue is air bubbles trapped in the wax. These can create defects in the final piece. To prevent this, ensure your wax model is well-crafted. Smooth surfaces help minimize air pockets. If bubbles do form, they can be repaired. Use a small tool to pierce them and fill in with extra wax.

Another challenge is achieving detail on intricate designs. Thin sections can easily break during casting. Artists should consider the thickness of their models. It may help to add slight supports. This can improve stability during the casting process. Also, monitoring temperature is essential. Too high can distort the wax; too low can lead to poor detail.

Flaws in the final product can also arise from improper metal pouring. Inconsistent pouring rates can create weak spots. It’s crucial to practice and refine this skill. Consistency can take time but is worth it for a quality outcome. Mistakes can turn into learning experiences. Embrace the imperfections and keep experimenting.

| Technique | Description | Common Challenges | Solutions |

|---|---|---|---|

| Investment Casting | A method that involves creating a mold from a wax model that is later melted away. | Mold distortion and wax residue. | Use high-quality molds and ensure proper temperature control. |

| Lost-Wax Casting for Small Sculptures | Ideal for fine details in small artworks, involving careful building of the wax model. | Risk of breaking delicate parts. | Reinforce delicate sections and handle with care. |

| Shell Building | A technique that creates a thick shell around the wax for durability. | Inconsistent shell thickness. | Monitor drying times and use multiple layers for uniformity. |

| De-waxing Process | Melting out the wax before metal pouring. | Incomplete wax removal. | Ensure thorough heating and proper ventilation. |

| Metal Pouring | The final step where molten metal is poured into the mold. | Issues with air bubbles and defects. | Pour metal slowly and at the right temperature to minimize bubbles. |

Lost wax casting is an intricate process that artists use to create beautiful metal sculptures. To enhance detail and quality in casted pieces, experts suggest several actionable strategies. One key factor is the investment material. Using a high-quality investment mix not only improves detail but also reduces surface imperfections. Reports show that precise control of temperature during the pouring process can significantly affect the final outcome.

For more intricate designs, consider refining your wax model meticulously. Carve deep, clean lines to achieve better results during the casting phase. Minor mistakes in this stage can amplify in the final piece. The precision of your original model plays a critical role. It’s recommended to invest time honing this aspect, as it pays off later.

Tips include constantly monitoring your environment. Humidity can affect wax, leading to inconsistencies. Keep your workspace organized to avoid distractions during critical processes. Always remember to test smaller projects before committing to larger works, as this can expose gaps in your technique. Reflect on your past projects; analyze what worked and what didn’t. Continuous improvement is essential in mastering lost wax casting.