The landscape of the Steel Casting Foundry industry is rapidly evolving. As we approach 2026, innovations and trends shape this essential sector. Companies are increasingly investing in advanced technologies. Automation and AI are making significant impacts. They enhance precision and reduce costs.

Sustainable practices are also gaining traction in steel casting. Foundries are looking for greener alternatives. They aim to minimize waste and energy consumption. This shift reflects a broader industry commitment to sustainability. However, not all foundries are adapting quickly. Some struggle to keep up with the pace of change.

Moreover, workforce challenges persist in the Steel Casting Foundry sector. Skilled labor shortages can hinder innovation. Training programs may not fully address the skill gap. This creates anxiety among industry leaders. Overall, the future holds promise but also demands reflection. Embracing change is essential for survival.

The steel casting foundry industry is on the brink of significant transformations as we look toward 2026. With increasing demand for lightweight and durable components, companies must adapt rapidly. Embracing innovations like 3D printing in molding processes could streamline production and reduce waste. However, these technologies require a steep learning curve. Not all foundries are ready to embrace such changes.

Growth projections indicate a shift towards sustainable practices. Many foundries are exploring eco-friendly materials to minimize their carbon footprint. Additionally, automation is becoming more prevalent. Robotics can enhance precision and efficiency. Yet, there are challenges in finding skilled labor to handle these advanced systems. Training programs need to keep pace.

As customer expectations evolve, foundries face pressure to deliver better quality and shorter lead times. Adopting intelligent manufacturing systems might be valuable. These systems enable real-time monitoring and adjustments, boosting productivity. However, the upfront investment can be daunting for smaller operations. Balancing growth with practicality will be crucial for success.

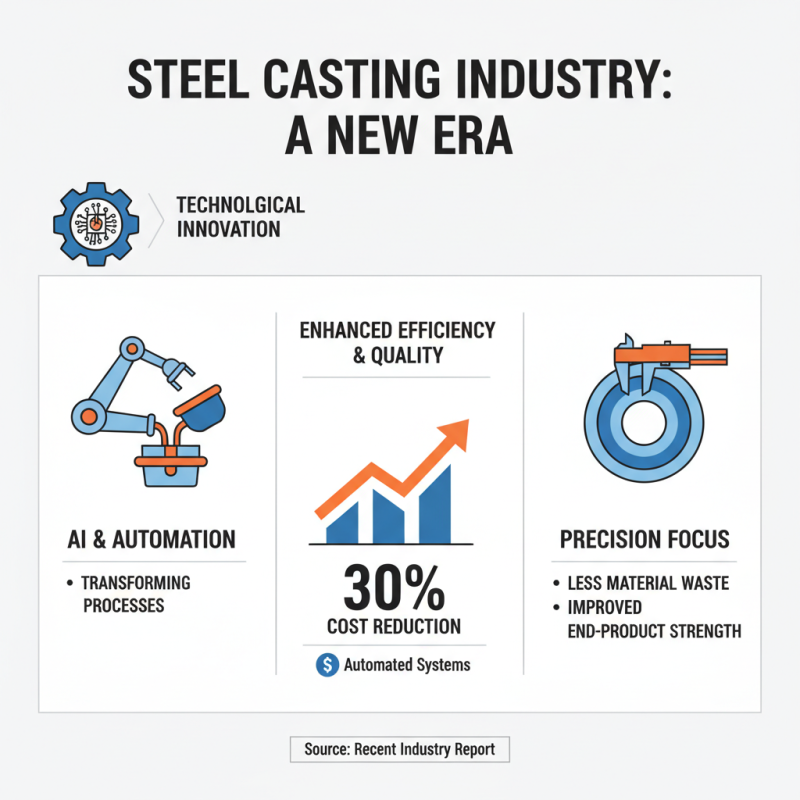

The steel casting industry is experiencing a paradigm shift, largely influenced by technological innovations. AI and automation are transforming traditional processes, enhancing efficiency and quality. A recent industry report noted that automated casting systems can reduce production costs by up to 30%. This shift allows foundries to focus on precision, resulting in less material waste and improved end-product strength.

AI systems analyze vast datasets to predict defects before they occur. This proactive approach minimizes errors in the casting process. One study highlighted that AI-driven monitoring can increase output quality by 25%. However, the integration process is not without challenges. Many foundries struggle with the high initial costs and training staff to adapt to new technologies.

Automation also raises concerns about workforce displacement. Skilled labor remains essential, yet many fear that jobs may be lost to machines. Balancing technological advancement with human expertise will be critical for future growth. A hybrid model, where machines assist rather than replace workers, could emerge as the ideal solution. The road ahead is filled with potential hurdles, but the rewards of innovation seem promising for the steel casting field.

Sustainability is reshaping the steel casting industry. A growing number of foundries are adopting recycling initiatives. In recent years, around 70% of scrap metal in steel production was recycled. This shift reduces waste and conserves resources effectively.

Eco-friendly practices are gaining momentum. Many foundries are utilizing electric arc furnaces, which can reduce carbon emissions by up to 75%. This technology not only lowers energy consumption but also minimizes pollution. Yet, some challenges remain. The transition requires substantial investment and skilled labor.

Recent studies indicate that consumer demand for sustainable products is rising. Nearly 65% of customers prioritize eco-conscious manufacturers when making purchasing decisions. Foundries must adapt to this trend to stay competitive. Embracing sustainability is not just an obligation; it is a pathway to innovation in steel casting.

This chart illustrates the projected trends in sustainability practices within the steel casting industry by 2026, focusing on the percentage of foundries adopting various eco-friendly practices.

The steel casting industry is witnessing rapid growth, especially in emerging markets. Countries like India, Brazil, and Vietnam are stepping onto the global stage. These nations offer vast natural resources and a young workforce. Their economic growth fuels demand for various steel products, including automotive and construction components.

However, challenges exist. Infrastructure and technological hurdles can stall progress. Many companies struggle with outdated practices. Transitioning to automation and advanced manufacturing techniques remains a daunting task. Investing in research and development can lessen these issues. Yet, many firms lack the capital needed for such innovations.

The potential for growth in steel casting is immense. Improved supply chains can enhance production efficiency. Partnerships can also open new opportunities. Innovators should focus on sustainability. Eco-friendly practices might attract more investment. The landscape will only evolve with commitment and strategic planning.

The steel casting industry is evolving, driven by new standards in quality assurance. Recent reports show that around 70% of foundries are adopting advanced testing methods to meet these standards. Testing techniques like ultrasonic testing and X-ray inspections are becoming commonplace. These technologies help detect flaws that could compromise product integrity.

However, implementing these new methods isn't without challenges. Training staff to handle advanced equipment is a significant hurdle. Many foundries report that a skilled labor shortage complicates the transition. This gap in skills can lead to inconsistencies in the quality assurance process. If left unaddressed, it may increase defects in castings, undermining customer trust.

Industry data indicates that only 55% of foundries currently comply with emerging quality standards. This raises concerns about overall safety and performance. As a result, some foundries are reconsidering their approach. A focus on continuous improvement and investment in workforce training is essential to stay competitive. The future of steel casting demands both innovation and vigilance in quality assurance.

| Trend/Innovation | Description | Impact on Quality Assurance | Testing Methods |

|---|---|---|---|

| Advanced AI Integration | Utilizing AI for process optimization and defect detection. | Enhances precision in quality monitoring, reducing error rates. | Real-time quality analysis through AI algorithms. |

| Sustainability Practices | Adoption of eco-friendly materials and recyclability in processes. | Improves overall product life cycle and compliance with environmental standards. | Lifecycle assessment methods to evaluate sustainability. |

| Automation in Casting | Integration of robotics for casting operations. | Reduces human error and enhances repeatability in casting quality. | Automated inspections using vision systems. |

| New Alloys Development | Research into innovative alloy compositions for specific applications. | Enhances material properties and application performance. | Mechanical testing for properties assessment. |

| Industry 4.0 Implementation | Smart manufacturing practices using IoT and big data. | Enables predictive maintenance and enhances overall efficiency. | Data analysis for predictive quality control. |