In the competitive realm of Stainless Steel Fabrication, staying ahead of trends is crucial for success. Expert John Smith, a renowned figure in the industry, emphasizes, “Innovation shapes the future of fabrication.” As we approach 2026, a fresh wave of trends emerges, promising to revolutionize processes and enhance productivity.

Manufacturers must keenly observe advancements like automation, digitalization, and sustainable practices. These trends can seem overwhelming, yet they are vital. Embracing new technologies can streamline production and reduce waste in Stainless Steel Fabrication. However, many companies struggle to adapt quickly, risking their competitive edge.

Reflecting on past challenges can guide businesses today. Mistakes in neglecting new trends can lead to missed opportunities. Staying informed and responsive is essential, not just an option. As the industry evolves, the fabricators who adapt will pave the way for future success.

Emerging technologies in stainless steel fabrication are reshaping the industry landscape for 2026.

Automation is gaining traction. Robotics and AI streamline processes, reducing labor costs and error rates.

These innovations improve efficiency significantly.

Manufacturers can produce complex designs with precision and speed, giving them a competitive edge.

Advanced materials are also on the rise. New stainless steel alloys offer better corrosion resistance and strength.

Incorporating these materials can lead to longer-lasting products. However, switching to new alloys may require a review

of existing processes. This adjustment can be challenging.

Tips: Focus on training your workforce to adapt.

Invest in development programs that cover new technologies. Keep an eye on industry trends to stay ahead.

Experiment with small-scale projects before full implementation. Embrace failure,

as it provides valuable lessons.

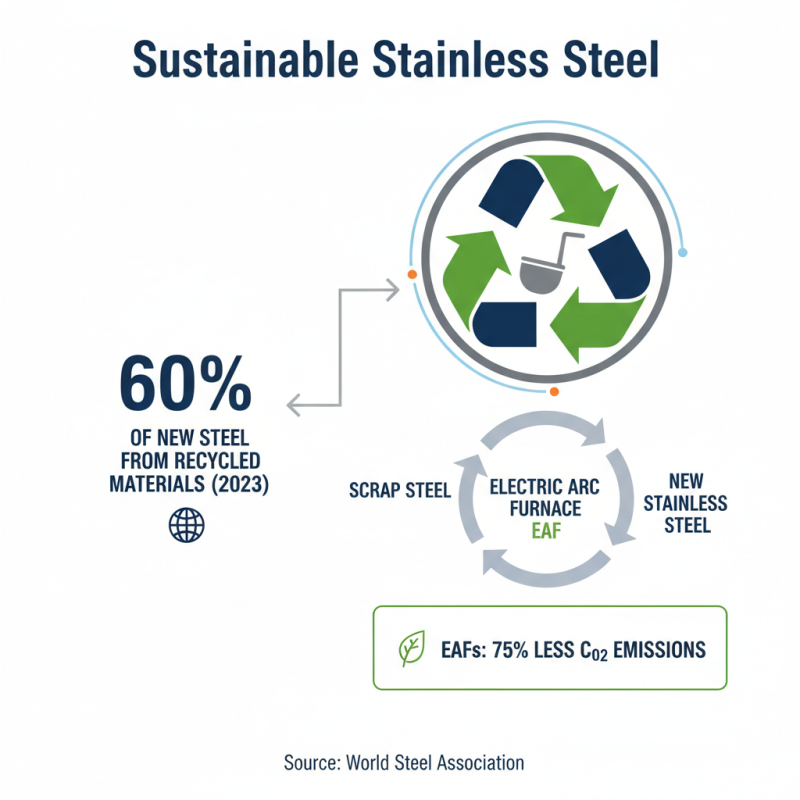

Sustainability in stainless steel production is gaining momentum. In 2023, the World Steel Association reported that 60% of the steel produced came from recycled materials. This data highlights the industry's shift toward circular economy practices. Many manufacturers are now utilizing electric arc furnaces, which use scrap steel instead of virgin materials. This process emits 75% less carbon dioxide.

Design practices are also evolving. Designers are prioritizing materials with lower environmental impact. Using stainless steel minimizes waste and enhances product lifespans. Steel's corrosion resistance reduces maintenance needs, further contributing to sustainability goals. According to a recent study, 30% of designers now factor sustainability into their initial concepts.

However, challenges remain. Sourcing recycled materials can be inconsistent. This inconsistency affects production timelines and costs. It's crucial for businesses to refine their supply chains. The industry must collectively address these hurdles while maintaining a focus on sustainable practices. Adopting innovative solutions is vital for future success in stainless steel fabrication.

The global demand for stainless steel is on the rise. Various industries, such as construction, automotive, and manufacturing, are driving this trend. Stainless steel is known for its durability and resistance to corrosion. These characteristics make it ideal for many applications.

In the construction sector, architectural designs increasingly incorporate stainless steel. It adds an element of modernity and strength. The automotive industry is also embracing lightweight materials. Stainless steel components can enhance fuel efficiency and performance. However, not all manufacturers adapt quickly. Some struggle with supply chain issues and sourcing high-quality materials.

Environmental concerns are also shaping the market. Companies face pressure to use sustainable practices. This includes recycling and reducing waste. While many are taking steps, some may not be doing enough. The challenge remains in balancing cost and sustainability. The evolving landscape requires constant adaptation to consumer expectations and industry standards. Companies must remain vigilant to succeed in this shifting market.

| Trend | Impact on Industry | Projected Growth (%) | Key Drivers |

|---|---|---|---|

| Sustainability Initiatives | Increased demand for eco-friendly products | 15% | Regulations, Consumer Preferences |

| Advanced Fabrication Techniques | Improved product quality and efficiency | 20% | Technological Advancements, R&D Investments |

| Customization and Flexibility | Tailored solutions for various industries | 10% | Client Demand, Market Competition |

| Digital Transformation | Streamlined operations and analytics integration | 25% | Automation, IoT Adoption |

| Market Diversification | Expansion into emerging markets | 30% | Global Trade, Economic Policies |

Innovative equipment and tools are transforming stainless steel fabrication. Advancements in technology lead to increased efficiency and precision. Semi-automated systems are gaining popularity. They reduce human error while improving output. However, the initial investment can be significant. Smaller businesses might struggle to adapt.

New cutting technologies are also emerging. Laser cutting is precise and versatile. It allows for intricate designs without extensive material waste. CNC machines enable complex shapes and sizes. Yet, these machines require skilled operators, creating a training challenge. Finding personnel with the right expertise is crucial for success.

Additionally, there is a growing trend toward sustainable practices. Energy-efficient machinery is becoming common. Businesses feel pressured to lower their carbon footprint. However, integrating these green technologies often raises costs upfront. Balancing sustainability and profitability is not straightforward. The industry must find ways to navigate these challenges effectively.

Quality control in stainless steel fabrication is vital for achieving excellence. Consistent quality checks can prevent defects and ensure durability. Regular inspections during the welding process can help identify issues early. It's often overlooked, but simple methods can make a big difference.

Using digital tools to monitor measurements can enhance precision. However, relying solely on technology without skilled operators can lead to errors. Training staff in quality benchmarks is necessary, but it's a challenge. Ongoing education should be a priority to address knowledge gaps.

Emphasizing communication among team members can improve outcomes. Feedback loops during production can reveal weaknesses in the process. Sometimes, teams assume everything is fine, but mid-production audits often tell a different story. Balancing real-time data with hands-on checks can bridge this gap.

This chart displays the anticipated growth in various trends in stainless steel fabrication for 2026. The data showcases the percentage increase in areas such as automation, eco-friendly practices, and advanced welding techniques, which are crucial for business success and quality control in the industry.