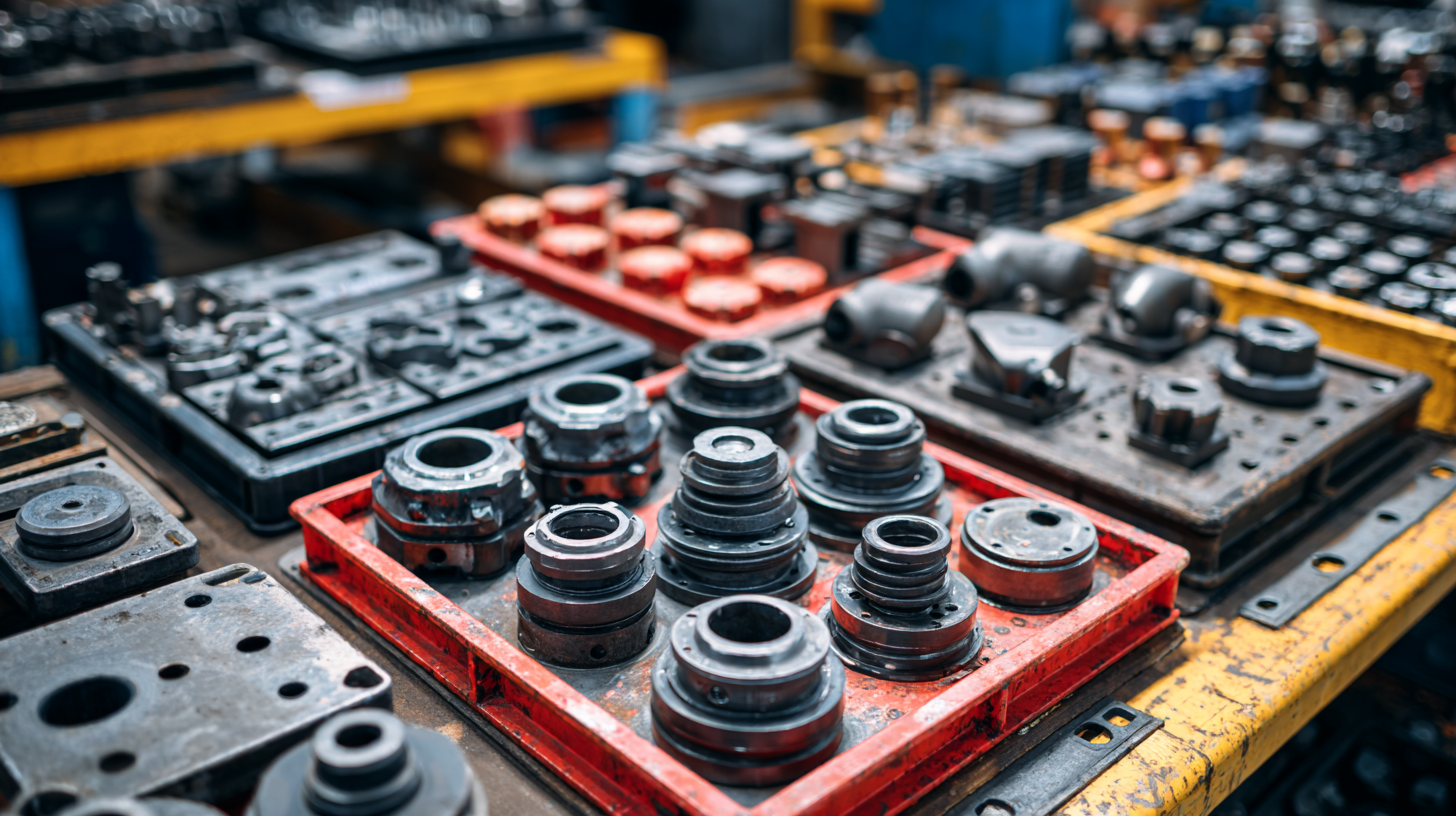

In an increasingly interconnected global marketplace, the importance of high-quality casting parts cannot be overstated. According to a recent report by Allied Market Research, the global casting market is projected to reach $263 billion by 2025, driven by the growing demand for automotive, aerospace, and industrial machinery sectors. This surge highlights the critical role that casting parts play in various supply chains, where precision and reliability are paramount. As manufacturers seek to enhance production efficiency and foster innovation, the reliance on trusted casting parts emerges as a key factor in ensuring quality and consistency. With China's advanced manufacturing capabilities and a commitment to excellence, businesses can leverage these dependable casting solutions to meet their global operational challenges. Ultimately, investing in superior casting parts not only optimizes supply chain performance but also reinforces a brand's reputation for quality across international markets.

The global supply chain is heavily reliant on the quality of casting parts, as they play a critical role in ensuring the efficiency and stability of production processes across various industries. Quality casting components not only enhance the integrity of finished products but also address the evolving demands of high-end manufacturing. In recent years, as highlighted by industry experts, the automotive supply chain has seen significant changes, with a clear shift toward more sophisticated and integrated supply relationships. Here, the importance of quality casting parts becomes even more pronounced, as they are essential for meeting the standards required for advanced vehicles and other high-tech applications.

Furthermore, the trend towards globalization in sectors such as automotive and machinery manufacturing underscores the necessity for reliable casting parts. As companies expand their operations internationally, the ability to source high-quality components becomes critical for maintaining competitive advantage and ensuring the security of the supply chain. With projections indicating substantial growth in the global metal casting market, industries must prioritize the acquisition of superior casting parts to navigate the complexities of today's supply chain dynamics effectively. High-quality casting not only optimizes production efficiency but also positions companies at the forefront of the market, allowing them to tackle future challenges confidently.

In today's competitive landscape, after-sales services play a crucial role in enhancing customer satisfaction and loyalty. According to a report by PwC, 73% of consumers state that customer experience influences their purchasing decisions, highlighting the importance of effective after-sales support in retaining clients. When businesses prioritize robust after-sales services, they not only address issues promptly but also foster a sense of trust and reliability among their customers. This ultimately reinforces brand loyalty, as a satisfied customer is likely to return and make repeated purchases.

To maximize the impact of after-sales services, companies should implement proactive communication strategies. Tips for success include regularly reaching out to customers post-purchase to gather feedback and identify areas for improvement. Additionally, providing comprehensive training and resource materials enables customers to utilize products fully, reducing potential frustrations and enhancing their overall experience. Research from the American Express Global Customer Service Survey indicates that 78% of consumers have backed out of a purchase due to poor customer service, making it imperative for businesses to prioritize support systems.

Another essential aspect is the integration of technology in after-sales processes. Utilizing customer relationship management (CRM) systems can help in tracking interactions and preferences, allowing businesses to offer personalized services that resonate with their clientele. A study by Salesforce revealed that 70% of consumers expect a company to understand their unique needs and preferences, underscoring the necessity of tailored after-sales strategies to cultivate long-lasting relationships.

Superior casting components play a crucial role in reducing maintenance costs within a global supply chain. According to a report by the American Foundry Society, the correct choice of casting materials can decrease maintenance expenditures by up to 25%. This reduction primarily stems from enhanced durability and performance, which translates into fewer downtimes and extended service life for critical machinery parts.

Moreover, advanced casting techniques, such as sand casting or die casting, have been shown to improve the precision and quality of components. A study from the International Journal of Advanced Manufacturing Technology indicates that precision cast components can reduce the need for replacements by 30%, further solidifying their economic benefits. By investing in high-quality casting parts, companies can not only enhance operational efficiency but also contribute to a more resilient supply chain capable of meeting global demands without frequent interruptions.

Sourcing casting parts in international markets can be a complex endeavor, but adhering to best practices can streamline the process and ensure quality. First, it's crucial to establish clear specifications and standards for the casting parts required. This clarity allows suppliers to provide accurate quotes and aligns their production capabilities with your expectations. Engaging with potential suppliers early in the process helps to build relationships and fosters open communication, which can lead to better negotiation outcomes and quality assurance.

Next, conducting thorough due diligence on potential suppliers is vital. This includes assessing their manufacturing capabilities, quality control processes, and financial stability. Visiting facilities, if possible, can offer invaluable insights into their operations and reliability. Additionally, considering local regulations and compliance standards is essential to avoid supply chain disruptions. By prioritizing these best practices, companies can source high-quality casting parts that not only meet technical requirements but also enhance overall supply chain efficiency.

| Reason | Description | Impact on Supply Chain |

|---|---|---|

| Quality Assurance | High-quality casting parts reduce defects and enhance product reliability. | Improves customer satisfaction and reduces return rates. |

| Cost Efficiency | Sourcing the right casting parts can lower production costs and increase margins. | Enhances overall financial performance of the supply chain. |

| Time to Market | Efficient sourcing and use of casting parts expedite the production process. | Gives a competitive edge by launching products faster. |

| Global Collaboration | Working with diverse suppliers fosters innovation and diverse solutions. | Enhances adaptability and resilience in the supply chain. |

| Sustainability | Utilizing sustainable casting materials contributes to environmental goals. | Improves brand image and meets regulatory compliance. |

In the competitive landscape of global supply chains, leveraging technology to improve the efficiency and performance of casting parts is critical. According to a recent report by MarketsandMarkets, the global investment in manufacturing technology, including casting processes, is projected to reach $1 trillion by 2026. This highlights a growing recognition of the importance of technological integration in production efficiency. Innovative techniques like additive manufacturing and advanced simulation software allow companies to optimize design and reduce waste, significantly impacting both cost and output quality.

Moreover, real-time data analytics and IoT (Internet of Things) applications have transformed how manufacturers track their casting processes. A study from McKinsey reveals that companies utilizing IoT technologies can achieve a 30% increase in operational efficiency. By monitoring machine performance and analyzing casting behavior, businesses can pinpoint inefficiencies and implement predictive maintenance strategies. This not only enhances the quality of casting parts but also ensures reliability across the supply chain, fostering a more resilient global operation. Embracing these technologies is no longer optional; it's essential for maintaining a competitive edge in the market.