The world of Metal Fabrication is evolving rapidly. As we approach 2026, it's essential to understand the emerging techniques and trends. John Smith, a renowned expert in the industry, once stated, "Innovation in metal fabrication will shape the manufacturers of tomorrow." His words highlight the importance of adapting to change.

New technologies are changing how we fabricate metals. Advanced welding methods, automated processes, and sustainable practices are becoming standard. These innovations not only improve efficiency but also reduce waste. However, challenges persist. Many companies struggle to keep up with these trends. A lack of skilled workers and high costs can hinder progress.

As we explore the best metal fabrication techniques to know in 2026, we must reflect on our practices. Embracing new ideas can be daunting. The industry must confront these issues head-on. Success requires a balance between tradition and modernity. Understanding these dynamics will ensure a robust future in metal fabrication.

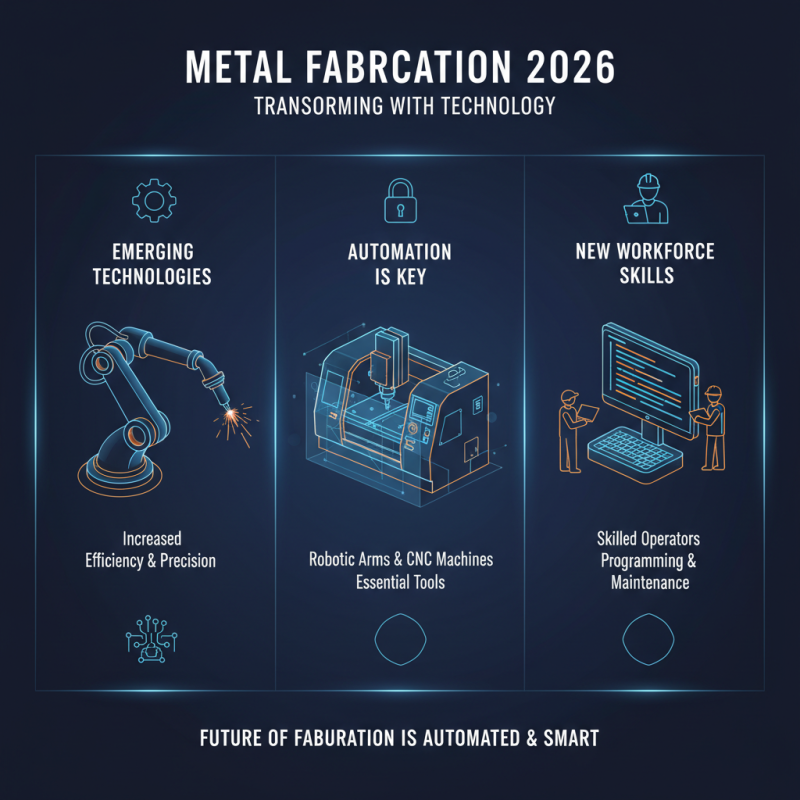

The landscape of metal fabrication is transforming rapidly as we approach 2026. Emerging technologies are driving efficiency and precision in the industry. Automation is becoming crucial. Robotic arms and computer numerical control (CNC) machines are not just trends; they are essential tools for the modern fabricator. These systems increase productivity but require skilled operators to program and maintain them.

Tips for adopting these technologies include investing in staff training. Workers need to be comfortable with both machines and software. Another tip is to conduct regular maintenance checks. Equipment downtime can lead to significant losses. It's also vital to stay flexible. Embrace change and be prepared to adapt processes as new techniques and tools emerge.

Additive manufacturing is another hot topic. It's not just for prototypes anymore; advanced techniques are allowing for end-use parts. This can save materials and reduce waste. Yet, it's important to analyze costs versus benefits. Not every project suits these new methods. It's crucial to weigh options and consider the project's unique needs before diving in. Flexibility and a willingness to learn will be key factors in navigating this evolving landscape.

The landscape of metal fabrication is evolving rapidly. One of the key trends is the integration of automation. With robotic systems taking on repetitive tasks, shops are seeing increased efficiency. Yet, this shift raises concerns. How do smaller businesses adapt to technology?

Another notable trend is the rising use of advanced materials. Lightweight alloys and composites are gaining traction. These materials promise strength without added weight. However, transitioning to new materials can be challenging. Fabricators must invest in training and equipment.

Sustainability is now a focal point in fabrication techniques. The push for eco-friendly practices shapes future methods. Recycling metal and minimizing waste are essential. Yet, balancing sustainability with profitability often proves difficult for many. As the industry moves forward, these trends highlight both opportunities and challenges.

Sustainability is crucial in metal fabrication for 2026. Companies are exploring eco-friendly practices. These methods reduce waste and energy consumption. There's a push toward using recycled materials. The goal is to minimize environmental impact.

Tip: Start by assessing your current processes. Identify areas with excessive waste. Small adjustments can lead to big improvements. For example, refining scrap handling can boost efficiency.

Aluminum is becoming popular again. It's lightweight and recyclable. Investing in technology helps reduce emissions during manufacturing. However, some firms face challenges in adopting these innovations. It's not easy, but every step helps.

Tip: Engage your team in sustainability efforts. Their insights can reveal hidden opportunities. Establish clear goals to drive change. Celebrate small wins to keep morale high.

As the metal fabrication industry evolves, new skill requirements emerge. Advanced techniques and technologies are reshaping the job landscape. According to a recent report by the Fabricators and Manufacturers Association, 52% of metal fabricators struggle to find skilled workers. This indicates a growing skills gap.

Welding automation is becoming a significant focus. Automated processes improve efficiency but demand new capabilities. Metal fabricators need to learn programming and maintenance of robotic systems. Familiarity with Industry 4.0 technologies is crucial. Fabricators should embrace data analysis and connectivity.

Soft skills are equally important. Communication and teamwork enhance productivity. Many professionals overlook these abilities. Understanding client needs can drive better outcomes. Embracing a culture of continuous learning is essential. The industry is not just about technical skills anymore; it is also about adaptability and foresight.

This chart represents the importance of various metal fabrication techniques in 2026, ranked on a scale of 1 to 10. The data reflects current trends and skill requirements for metal fabricators in an evolving industry.

The metal fabrication market is experiencing significant growth, fueled by rising industrial demand. In 2026, the market is projected to expand rapidly. Various sectors seek efficiency and precision. This need influences fabrication techniques.

Adoption of automation is changing the trade. Robotic systems are becoming more common. They enhance accuracy and reduce labor costs. However, there are concerns about job displacement. Some workers may need to adapt or learn new skills. Traditional methods still hold value. Balancing old techniques with modern ones is crucial.

Sustainability is another important focus. Many companies are exploring eco-friendly materials. Recycling metal has gained traction. Yet, not all processes are environmentally sound. Some practices still contribute to waste. The industry must address these conflicts to thrive and innovate.

| Technique/Trend | Description | Projected Growth (%) | Market Size (USD Billion) | Key Benefits |

|---|---|---|---|---|

| Laser Cutting | Highly precise cutting technique using laser technology. | 15 | 6.5 | Precision, speed, and minimal material waste. |

| 3D Metal Printing | Innovative additive manufacturing for complex metal structures. | 20 | 4.2 | Design flexibility and reduced lead times. |

| CNC Machining | Computer-controlled machining for high accuracy. | 10 | 8.0 | Consistency and ability to produce complex parts. |

| Robotic Welding | Automated welding process utilizing robotics for efficiency. | 18 | 7.5 | Increased production speed and quality control. |

| Sheet Metal Fabrication | Techniques for shaping and assembling sheet metal components. | 12 | 5.0 | Versatile applications across multiple industries. |