The Investment Casting Process has long been regarded as a cornerstone of precision manufacturing. Industry expert Dr. Robert Mason once stated, "Precision is the heart of investment casting." This process delivers intricate designs and optimal mechanical properties, making it invaluable in sectors like aerospace and automotive.

However, perfection in the Investment Casting Process remains elusive. Many manufacturers struggle with defects such as inclusions or dimensional inaccuracies. These issues can lead to increased costs and delays. For instance, a small misalignment can compromise a component's performance in critical applications.

As the industry moves toward 2026, it becomes essential to refine best practices. Innovations and training can help mitigate common pitfalls. A focus on quality control and material selection will be vital. Continuous improvement in the Investment Casting Process is not just a goal; it’s a necessity for sustainable success.

Investment casting, also known as lost-wax casting, is a precise manufacturing process. It allows for the creation of intricate designs and complex shapes. The process begins with a wax pattern that is coated in a ceramic shell. Once hardened, the shell is heated, and the wax is melted away, leaving a cavity for metal. This method is often used in aerospace and medical industries due to its ability to produce high-detail parts.

Tips: Always ensure proper design considerations. Avoid overly complex geometries that can complicate the process. Regularly assess your materials and equipment. Even slight variations in temperature can impact the final product quality.

After the metal is poured, it cools and solidifies. This stage requires careful monitoring to prevent defects. Common issues include bubbles and inclusions. These problems can lead to significant delays and extra costs. So, maintaining a clean workspace is crucial.

Tips: Implement consistent quality checks. Regular maintenance of your molds can enhance durability. Learn from each batch to improve your next run. Even small adjustments can lead to noticeable improvements.

Investment casting is a precise manufacturing process that relies heavily on the choice of materials. One of the key materials is the wax used for creating patterns. The wax must have a low melting point to facilitate easy removal, yet it should be durable enough to maintain detail. Finding the right wax can be challenging, as variations in composition can affect the final product's quality.

Another important material is the shell. Typically made from a mixture of silica and other bonding agents, the shell must withstand high temperatures. The thickness of the shell plays a crucial role in determining precision. A thinner shell can offer finer details, but it may require careful handling. Some foundries struggle with shell consistency, often leading to defects that necessitate rework.

Metals are the final component. Common choices include aluminum, steel, and bronze. Each metal has unique properties that affect strength and ductility. Some metals may be more prone to oxidation during casting, impacting the finish. Observing how these materials interact during the process can lead to improved outcomes. A meticulous approach can reduce waste and enhance productivity.

Investment casting is a complex process, often requiring careful planning. To start, a master pattern is created. This pattern outlines the desired shape and dimensions. It is typically made of metal or wax. The quality of the pattern is critical. Any imperfections can lead to flaws in the final product.

Next, a ceramic shell is formed around the pattern. This shell provides a mold for the molten metal. The thickness of the shell must be managed carefully. Too thick, and it adds unnecessary weight; too thin, and it may not hold up during casting. After drying, the shell is heated to remove the pattern. This step is crucial for creating a hollow cavity.

Once the shell is ready, molten metal is poured in. The temperature and timing here are key. Rushing this stage can result in defects. Finally, after cooling, the shell is broken away. The result reveals a cast that often requires additional finishing. It's important to evaluate the process and identify areas for improvement. Each step carries potential risks that must be addressed for a better outcome.

Investment casting often faces challenges that can significantly affect production efficiency and part quality. One common issue is mold wear, which can lead to dimensional inaccuracies in the final product. According to a recent industry report, 30% of manufacturers experience mold failures at least once during production. This can arise from improper materials or inadequate cooling systems. Implementing timely inspections and quality controls can mitigate these risks, ensuring better mold longevity.

Tip: Regularly assess your mold materials. Using high-performance alloys can enhance durability and precision.

Another significant challenge is controlling the filling rate during pouring. If the metal fills too quickly, it can cause defects like gas entrapment. Studies show that up to 15% of defects in cast parts result from improper pouring techniques. Operators should be trained to adjust speeds based on the specific characteristics of the metal and the design of the part. Continuous education can prevent costly errors.

Tip: Optimize pouring temperatures. Too high or too low can lead to serious quality issues.

Understanding these challenges is essential for success in investment casting. Operators must regularly revisit their processes, emphasizing adjustments and improvements. Making data-driven decisions can help identify where changes are needed. Regularly reviewing production metrics will support ongoing improvements.

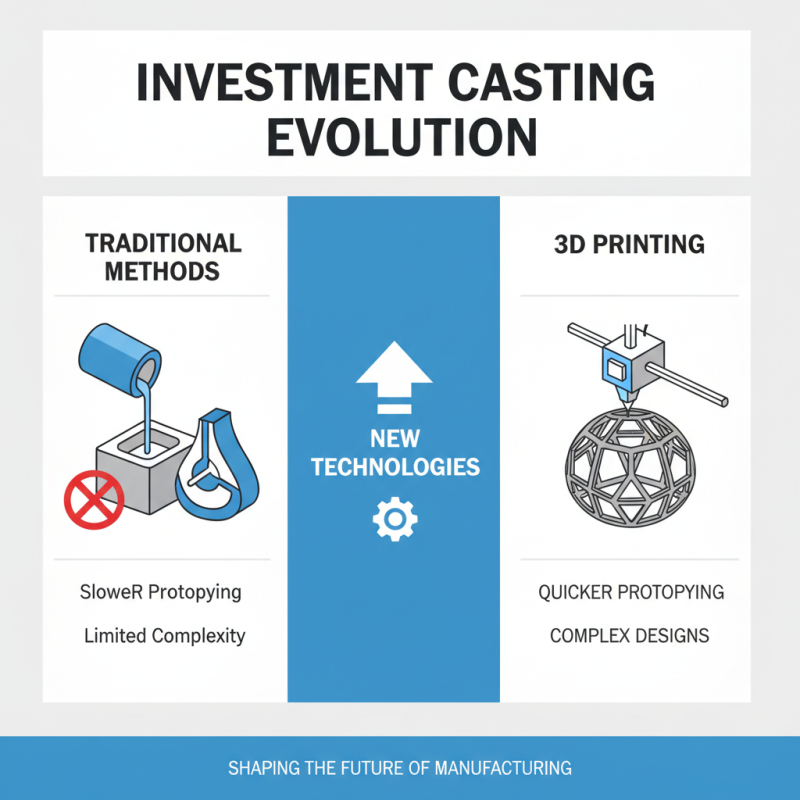

The investment casting process is evolving rapidly. New technologies are shaping the future of this industry. For example, 3D printing is making waves. It allows for quicker prototyping and more complex designs. Traditional methods often struggle with intricate shapes. 3D printing can handle these challenges with ease.

Tips: Always evaluate your designs for printing feasibility. Complex designs may need adjustments. Collaborate with engineers early in the process.

Moreover, sustainable practices are gaining traction. Manufacturers are focusing on reducing waste. Reusable materials and energy-efficient operations are key trends. However, implementing these changes can be difficult. It requires upfront investment and training.

Tips: Assess your current processes for waste generation. Make small, incremental changes. It’s often easier than a complete overhaul.

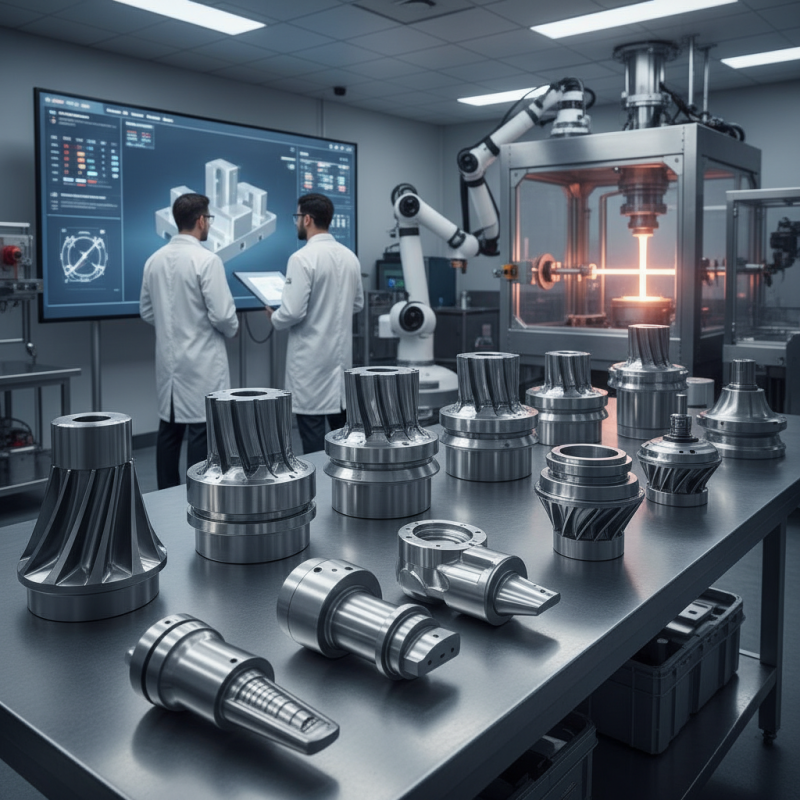

Lastly, automation is becoming prevalent. Robots can perform repetitive tasks with precision. This can increase efficiency and reduce errors. However, relying too much on machines can be risky. Human oversight is still crucial for quality assurance.

Tips: Regularly monitor automated systems. Ensure they align with project standards. Balancing technology and human skill is essential.