Choosing the best Stainless Foundry is crucial for high-quality metal castings. A reliable foundry can dramatically impact the final product. Quality castings ensure durability and performance in various applications.

When selecting a Stainless Foundry, consider several factors. Experience matters. A long history often indicates a commitment to high standards. Look for certifications and customer testimonials. These can provide insights into their capabilities.

Not all foundries are the same. Some might lack precision in their processes. Others may not prioritize quality control. Reflect on past projects and how they align with your needs. Examine potential shortcomings. Finding the perfect fit requires careful consideration. It’s not just about the price; it’s about value and reliability.

Choosing the right stainless foundry significantly impacts the quality of metal castings. A high-quality foundry employs skilled artisans and uses advanced technology. This combination ensures precision in every piece. Quality raw materials are also crucial. Inferior materials lead to weak castings. It's essential to assess the foundry's sourcing practices.

Communication with the foundry is vital. Clear expectations must be outlined from the start. This includes sharing specific design details and performance requirements. Misunderstandings can cause delays and subpar products. Regular check-ins provide opportunities to address potential issues. Trust in the foundry's expertise balances innovation and tradition.

Many companies prioritize cost over quality. While saving money is important, it can compromise product integrity. In the long run, poor castings can lead to failures, impacting safety and performance. It’s a dilemma between budget constraints and the risk of substandard quality. Engaging a foundry with a proven track record may require a larger initial investment but pays off over time.

When evaluating high-quality stainless foundries, several factors come into play. Firstly, the foundry's capabilities in producing complex geometries are crucial. Reports indicate that about 70% of metal casting failures arise from design flaws. This highlights the need for precision in design and production processes. The foundry's experience with various stainless steel alloys also affects quality. Foundries familiar with specific grades tend to yield better results.

Another important criterion is the quality control measures in place. A recent industry survey revealed that 60% of foundries lack stringent quality checks, leading to inconsistencies in castings. This can result in significant rework costs. It's essential to assess whether the foundry employs advanced techniques like non-destructive testing or real-time monitoring during production.

Additionally, customer feedback provides insight into a foundry's reliability and performance. A study found that 55% of buyers will reconsider future orders if they experience subpar service or product variability. For high-stakes projects, a foundry’s reputation can heavily influence business outcomes. Investing time in due diligence is critical. Every detail matters in ensuring the final product meets industry standards.

| Criteria | Rating Scale | Importance (1-5) | Comments |

|---|---|---|---|

| Material Quality | 1-10 | 5 | High-grade stainless steel ensures durability and corrosion resistance. |

| Production Techniques | 1-10 | 4 | Advanced CNC machining and casting methods are preferred. |

| Certifications | Pass/Fail | 5 | ISO 9001 or other relevant certifications demonstrate quality standards. |

| Lead Time | Days | 3 | Timely production and delivery are crucial for project scheduling. |

| Customer Service | 1-10 | 4 | Responsive communication and support enhance collaboration. |

| Post-Sale Support | 1-10 | 3 | Assistance with installation and troubleshooting is beneficial. |

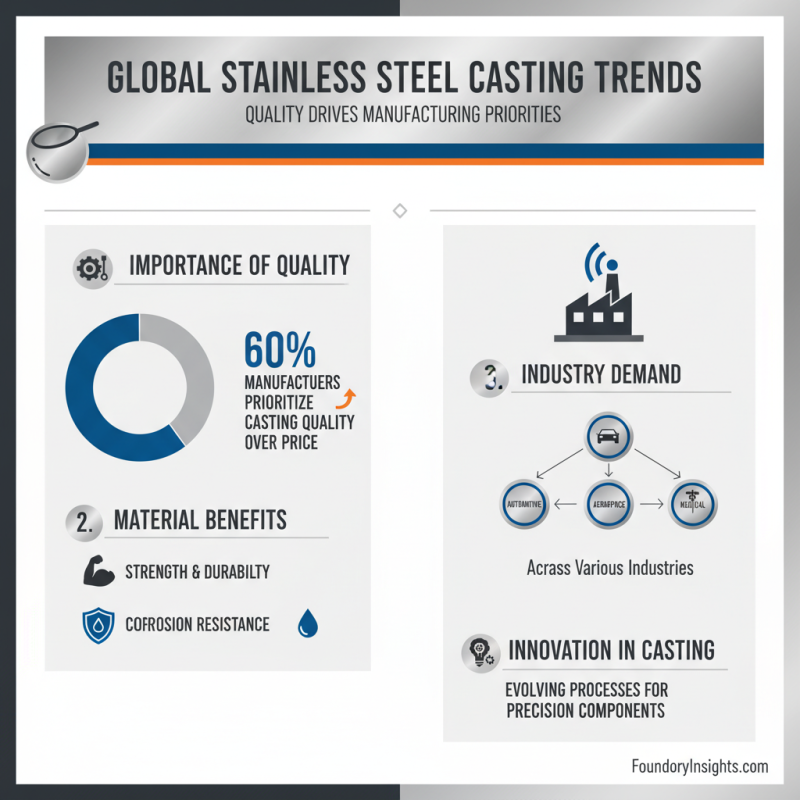

The search for top stainless foundries often highlights the importance of quality metal castings. Reliable data indicates that approximately 60% of manufacturers prioritize casting quality over price. This reflects a growing demand for durable and precise components across various industries. Stainless steel castings are particularly favored for their strength and resistance to corrosion. As industries evolve, the need for innovative solutions in casting processes becomes paramount.

Many foundries have developed a reputation for excellence. They achieve this through advanced techniques like investment casting and sand casting. Recent studies show that these methods can enhance dimensional accuracy by over 15%. However, not all foundries deliver consistency. Some struggle with quality control, resulting in defects that can compromise the reliability of castings. Industry experts suggest that suppliers must focus on regular audits and employee training to minimize these issues.

Selection of a foundry requires diligence. Quality certifications, such as ISO, are essential indicators. They illustrate a foundry's commitment to maintaining high standards. Despite this, even certified foundries may face challenges, particularly with fluctuating raw material costs. This can lead to variability in the final product. Thus, finding the best stainless foundry is a nuanced process, requiring careful consideration of both quality and reliability.

Innovative techniques in stainless steel casting are transforming the industry. Many foundries are adopting advanced methods to enhance production efficiency and improve quality. For instance, the use of 3D printing for mold creation has reduced lead times significantly. Recent reports indicate that companies using this technology can cut production time by up to 40%. This shift allows for more complex designs without compromising quality.

Tips: Consider the importance of mold design. Investing in high-quality molds can lead to better final products. Regular maintenance of equipment is also crucial. This helps avoid defects in castings, which can be costly.

While progress is evident, challenges remain. Not all foundries can keep pace with technological advancements. Some still rely on traditional methods, leading to longer production cycles. This can hinder competitiveness in a rapidly evolving market. Data suggests that about 30% of foundries have yet to adopt modern casting techniques. Acknowledging and addressing these gaps is essential for future growth.

In the world of metal castings, the quality of materials is crucial. High-quality stainless steel significantly improves the performance of casted products. It resists corrosion and extends the lifecycle of components. Moreover, it enhances overall strength and durability, making castings more reliable under stress.

Not all foundries prioritize material quality. Some may cut costs, using subpar materials. This can lead to failures or defects in the final product. Even a slight compromise in material quality can drastically affect performance. It’s essential to scrutinize the foundry's practices. How do they source their materials? This question matters.

A foundry’s reputation often hinges on its commitment to quality. Premium materials should be a standard, not an exception. Check for certifications and quality control measures. If a foundry lacks transparency, that could be a red flag. Quality assurance is an ongoing journey, not a destination. Businesses must continuously evaluate their choices to assure long-term success.