In today's industrial landscape, the significance of casting pump parts cannot be overstated. According to the latest reports by the Research Institute for Advanced Manufacturing, the global market for cast metal products, which prominently includes pump components, is projected to surpass $95 billion by 2026. This growth emphasizes the critical role that high-quality casting plays in enhancing the performance and durability of pumps used across various sectors, including oil and gas, water management, and chemical processing.

With the demand for efficient and reliable pumping systems escalating, manufacturers are increasingly turning to advanced casting techniques to ensure optimal function and lifespan of their products. Understanding the impact of casting pump parts not only aligns with industry standards but also drives innovation, ultimately leading to greater operational efficiency and sustainability in industrial applications.

With the demand for efficient and reliable pumping systems escalating, manufacturers are increasingly turning to advanced casting techniques to ensure optimal function and lifespan of their products. Understanding the impact of casting pump parts not only aligns with industry standards but also drives innovation, ultimately leading to greater operational efficiency and sustainability in industrial applications.

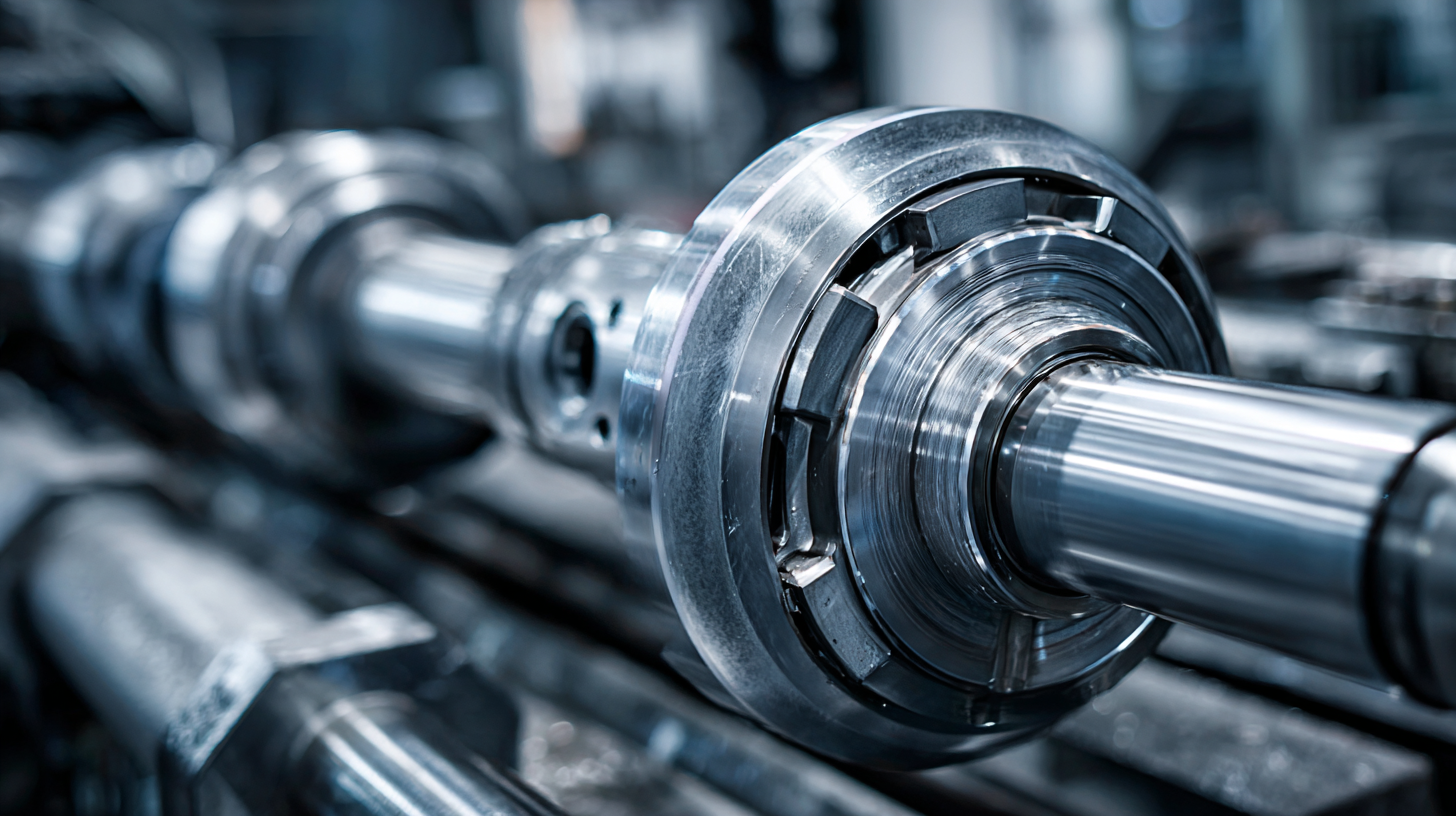

In the realm of industrial applications, the design and durability of pump components are crucial for efficiency and reliability. Casting plays a pivotal role in this context, as it allows for the creation of complex geometries that meet the specific requirements of various pumping systems. Through processes like sand casting or die casting, manufacturers can produce intricate designs that can accommodate the flow dynamics and stress distributions expected in operational environments. These techniques not only facilitate the production of custom shapes but also ensure that the components are engineered to withstand harsh conditions, such as corrosive liquids or high-pressure scenarios.

Moreover, the durability of cast pump parts is significantly enhanced through the selection of appropriate materials and casting techniques. Advanced alloys and composites can be used to improve resistance to wear and tear, extending the life of the pumps they compose. The casting process itself allows for better control over the material properties, leading to a more uniform structure that mitigates the risk of failure under load. As industries increasingly seek sustainable solutions, understanding how casting contributes to the design and longevity of pump components becomes essential for optimizing performance and reducing operational costs.

| Dimension | Casting Material | Application | Durability | Cost Efficiency |

|---|---|---|---|---|

| 5 inches | Ductile Iron | Water Pumps | High | Moderate |

| 8 inches | Cast Steel | Slurry Pumps | Very High | High |

| 10 inches | Aluminum | Chemical Pumps | Moderate | Low |

| 12 inches | Bronze | Marine Pumps | High | Moderate |

In industrial applications, the choice of materials for casting pump parts is critical to ensure efficiency, durability, and reliability. One of the most commonly used materials is cast iron, well-known for its excellent wear resistance and ability to withstand high pressure. Its self-lubricating properties reduce friction in moving parts, enhancing performance and minimizing maintenance costs. Additionally, cast iron’s ability to absorb vibrations makes it suitable for various pump types, contributing to a smoother operation.

Another important material in the casting of pump parts is stainless steel, recognized for its corrosion resistance and strength. Particularly beneficial in environments where pumps come into contact with aggressive chemicals, stainless steel parts offer longevity and reliability. Furthermore, alloys such as bronze and aluminum are also utilized for their lightweight nature and resistance to corrosion, making them ideal for specific applications where weight constraints are a consideration.

Ultimately, the careful selection of materials in casting not only optimizes pump performance but also extends the lifespan of the equipment, ensuring smoother operations in industrial sectors.

In the realm of industrial applications, the casting of pump parts plays a critical role in enhancing performance and ensuring reliability. Common casting techniques, such as sand casting, investment casting, and die casting, provide manufacturers with the flexibility to produce complex geometries and durable components.

Sand casting, for instance, is widely favored due to its cost-effectiveness and the ability to create large parts, which is crucial for pumps handling substantial fluid volumes. According to a recent market research report by Research and Markets, the global industrial pump market is projected to reach $80 billion by 2027, indicating the growing demand for high-quality casting techniques that can withstand harsh operating conditions.

Sand casting, for instance, is widely favored due to its cost-effectiveness and the ability to create large parts, which is crucial for pumps handling substantial fluid volumes. According to a recent market research report by Research and Markets, the global industrial pump market is projected to reach $80 billion by 2027, indicating the growing demand for high-quality casting techniques that can withstand harsh operating conditions.

Investment casting, another prominent technique, allows for high precision and a superior surface finish, which is essential for reducing friction and wear in pump applications. This method results in more intricate designs, permitting manufacturers to create lightweight components without sacrificing strength. Data from a recent study by Grand View Research highlights that pumps manufactured using advanced casting methods can lead to efficiency gains of up to 15%, significantly impacting overall operational costs for industries reliant on heavy-duty pump systems. As such, the choice of casting technique is instrumental in meeting the performance standards required in today's competitive industrial landscape.

In industrial applications, cast pump parts play a crucial role in efficiency and reliability. To maintain their performance and extend their lifespan, it's essential to adhere to best practices in maintenance. Regular inspections are paramount; by identifying wear and potential issues early, operators can prevent costly downtime and extend the service life of the pumps.

Tips: Always schedule periodic maintenance checks based on the manufacturer’s recommendations. During these inspections, focus on checking for signs of corrosion, cracks, or other materials that could impact the integrity of the cast components. Keeping a detailed maintenance log helps track performance and maintenance schedules.

Another key practice involves proper cleaning techniques. Accumulation of debris or corrosive substances can lead to premature failure of cast parts. Using appropriate cleaning solutions that are compatible with the materials of the pump ensures a longer life.

Tips: After each cleaning session, inspect the pump parts for any signs of wear or damage. Implementing a routine cleaning schedule can significantly minimize the risk of damage and ensure optimal performance in demanding industrial environments.

In today's industrial landscape, the cost-effectiveness of cast components in pump engineering cannot be overstated. According to a report by the Global Casting Market Insights, the casting industry is projected to reach a valuation of $150 billion by 2026, driven by increasing demand for durable and customizable components across various sectors, including water, oil, and energy. Cast pump parts, such as casings and impellers, play a crucial role in enhancing the efficiency and longevity of pumping systems. Their ability to withstand high pressures and corrosive environments makes them a preferred choice for manufacturers.

Furthermore, a study published by the American Foundry Society highlights that incorporating cast components can reduce overall manufacturing costs by up to 30%. This reduction is primarily due to economies of scale, reduced machining times, and lower material wastage. As industries continue to seek both performance and operational efficiency, adopting cast components for pump applications proves to be a strategic investment. The initial costs of casting may be higher compared to other manufacturing processes, but the long-term benefits, including maintenance savings and improved operational reliability, make cast pump parts a viable solution for industrial applications today.

This chart illustrates the cost comparison between different materials used in pump engineering, highlighting the significance of cast components. The data represents the average cost per unit for various pump parts and showcases the advantages of using cast materials in industrial applications.