Choosing the right Steel Casting Foundry is crucial for the success of your project. According to industry expert John Smith, "The foundation of a great project lies in selecting the right foundry." A foundry's capabilities can greatly affect the final product's quality and performance. It’s not just about finding the cheapest option; the expertise and technology at a foundry play a significant role.

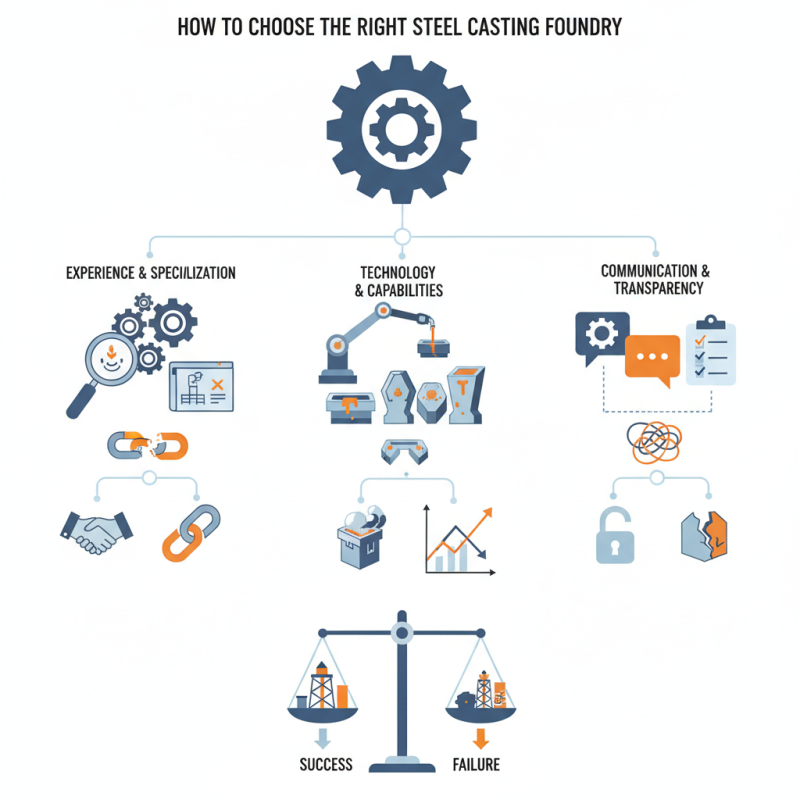

When selecting a Steel Casting Foundry, factors such as experience and specialization matter. A foundry that has worked on similar projects might better understand your needs. Nevertheless, some may overlook this aspect, leading to significant issues down the line. It's a common pitfall in the industry.

Communication is another critical factor. Proper dialogue can reveal a foundry's commitment to quality and service. However, some foundries may not provide clear information, creating confusion. It's essential to reflect on the importance of transparency. Ultimately, the right Steel Casting Foundry can be the difference between a project’s success and failure.

Steel casting is a method used to shape steel into various forms, enabling its wide application across industries. It involves pouring molten steel into a mold, where it cools and hardens. This process is essential in producing complex shapes that would be difficult or impossible to create otherwise. According to a report by Market Research Future, the global steel casting market is projected to reach $250 billion by 2025, reflecting its vital role in sectors like automotive and construction.

Applications of steel casting are myriad. It is used to manufacture critical components such as engine blocks, gears, and construction fittings. However, challenges exist in achieving quality and performance consistency. A study revealed that nearly 30% of steel casting defects stem from temperature variations during production. This illustrates the need for foundries to maintain strict control measures. Understanding these nuances is crucial for selecting the right foundry for a specific project.

In addition to quality, cost is a significant factor. High-quality steel casting can come at a premium. Yet, compromising on quality may lead to higher long-term costs due to unsatisfactory products. A delicate balance must be struck between price and quality. Being aware of these factors can guide decision-making in the steel casting selection process.

| Casting Process | Material Used | Typical Applications | Advantages | Considerations |

|---|---|---|---|---|

| Sand Casting | Carbon Steel | Automotive Parts, Machinery Components | Cost-effective, Versatile | Surface Finish, Dimensional Tolerances |

| Investment Casting | Stainless Steel | Aerospace, Medical Equipment | High Precision, Complex Shapes | Higher Cost, Longer Lead Time |

| Die Casting | Aluminum Alloy | Consumer Electronics, Automotive | High Production Rate, Excellent Finish | Initial Tooling Cost, Limited Alloys |

| Shell Molding | Gray Iron | Heavy Equipment, Valve Bodies | Good Dimensional Accuracy, Smooth Surface | Material Limitations, Cost |

Choosing the right steel casting foundry can significantly impact your project's success. Key factors include quality, capacity, and technical expertise. According to the World Steel Association, the global steel production reached 1.9 billion tons in 2022. This underscores the vast supply chain involved in casting. However, not all foundries can meet high-quality standards.

Quality control is crucial. A foundry should have robust testing procedures. Look for certifications like ISO 9001. Reports indicate that 30% of casting defects occur due to inadequate quality assurance. This can lead to project delays. Understanding a foundry's production capacity is likewise critical. A mismatch may hinder your project's timeline.

Communication and technical support are often overlooked. A foundry with responsive customer service is essential. Establish dialogue and understand their design capabilities. In an industry where 60% of projects face unforeseen challenges, reflecting on these aspects can reveal missed opportunities. Don't underestimate the value of a foundry's expertise and experience. It can make all the difference in your project's outcome.

This bar chart illustrates the importance ratings of various factors to consider when selecting a steel casting foundry. Factors like experience and quality control are rated higher in importance, which highlights their critical role in ensuring a successful casting project.

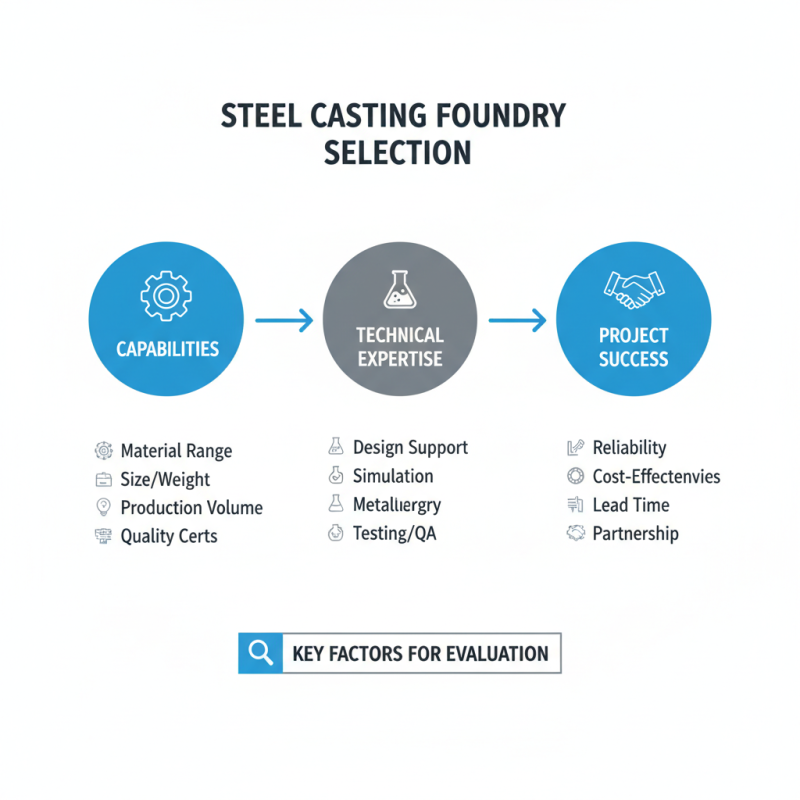

Choosing the right steel casting foundry is crucial for project success. Evaluating their capabilities and technical expertise can seem daunting. However, there are key factors to consider that can simplify this process.

First, assess the foundry’s experience in your specific industry. A foundry with a proven track record in similar projects is preferable. Look for case studies or references. These insights can reveal their strengths and weaknesses. You might find that some foundries are excellent in design but struggle with quality control.

Tips: Ask for samples. They can showcase the foundry's craftsmanship and attention to detail. A well-crafted sample often reflects their commitment to quality.

Next, consider their technical capabilities. Check if they possess advanced machinery and technologies. Modern tools can increase efficiency and precision. Yet, some foundries may have outdated equipment. This could lead to delays and inconsistencies. Don’t hesitate to visit the facility. Observing their operations can provide valuable insight.

Tips: Engage with their engineers. Their expertise can be an asset. You’ll want to ensure they understand your requirements clearly. Communication here is key. Misunderstandings can lead to complications later.

In the end, choosing a foundry is about finding a partner in your project. Be diligent, and don’t rush this critical decision. Understanding their strengths and limitations is vital.

Choosing the right steel casting foundry is crucial for project success. Quality standards and certifications matter a lot. They help ensure that the foundry meets specific requirements. You should check for ISO certifications. These certifications indicate a standard level of quality.

It's also important to look for industry-specific standards. Some foundries may have certifications that cater to unique industries. For instance, automotive or aerospace certifications can showcase a foundry's expertise. However, not all foundries maintain these standards consistently. Some may hold expired certifications, which could be a red flag.

Ask for recent quality control reports. These documents can provide insights into the foundry’s operational practices. Regular quality audits are also a good indicator of a foundry’s commitment to excellence. However, keep in mind that even highly certified foundries can experience issues. Quality can fluctuate based on many factors. Transparency about these aspects is key. While certifications help, you should not rely solely on them.

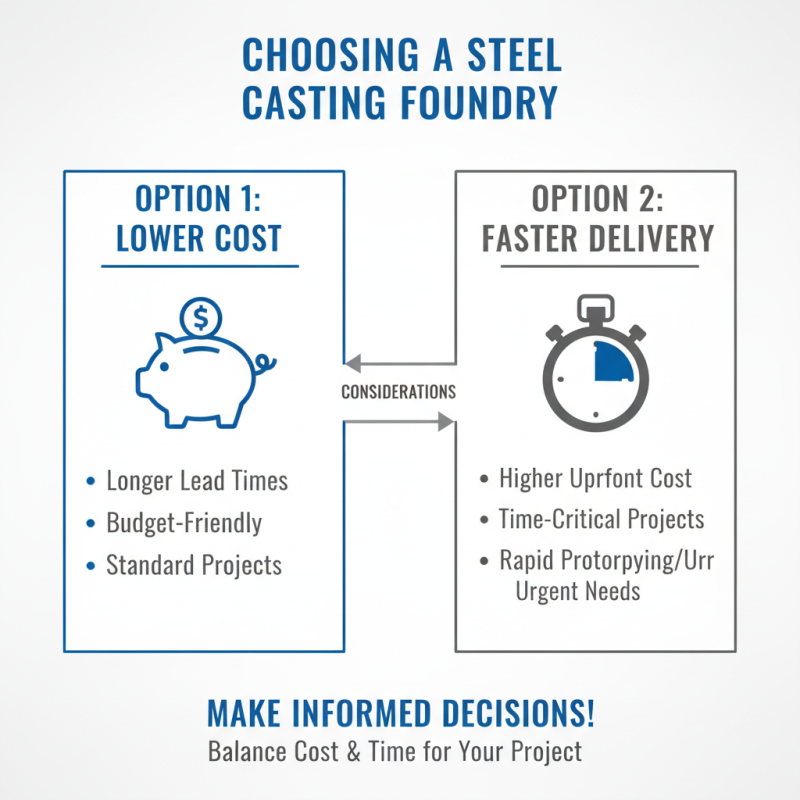

Choosing the right steel casting foundry is crucial for your project. Costs and lead times can vary significantly. Understanding these differences helps in making an informed decision. Some foundries may offer lower pricing but take longer to deliver. Others may provide quicker turnarounds but at a higher cost.

Consider what’s most important for your project. Are you tightly bound by budget constraints? Or is time your primary concern? Engaging multiple foundries for quotes may reveal surprising disparities. Remember, the cheapest option might not necessarily meet your quality standards.

Lead times can be impacted by various factors. A foundry with a full order book may delay your project. Conversely, a foundry eager for business might expedite your order. Each option comes with trade-offs. Weighing these pros and cons is vital. Reflect on your priorities as you explore your choices. A well-informed decision leads to better results.