In the rapidly evolving landscape of manufacturing and technology, selecting the right CNC parts has become crucial for staying competitive in 2025 and beyond. As industries embrace advancements such as automation, smart manufacturing, and sustainability, the demand for high-quality CNC components continues to grow. This blog aims to guide businesses in navigating these trends by providing insights into the characteristics of top-tier CNC parts that align with future industry needs. From understanding the materials and precision required to evaluating supplier reliability and innovation, we will explore how making informed choices in CNC parts can drive efficiency and productivity. As we look ahead, it’s essential to comprehend the factors influencing the marketplace and to prepare strategically—ensuring that your operations are not only current but future-ready.

In the rapidly evolving landscape of CNC manufacturing, understanding the importance of import and export certifications is crucial for businesses looking to stay competitive. These certifications not only ensure compliance with international standards but also enhance the credibility of CNC parts. By securing the necessary certifications, companies can minimize risks related to quality and regulatory compliance, ultimately facilitating smoother transactions across borders.

When selecting CNC parts, it's essential to prioritize suppliers that hold relevant certifications. This not only guarantees the quality of the products but also simplifies the import and export process by ensuring that all required documentation is in order. Companies should also stay informed about the changing regulations in different markets, as this knowledge can influence procurement decisions.

Tips for navigating the certification landscape include conducting thorough research on regional requirements and seeking suppliers with a proven track record in certification compliance. Additionally, consider investing in training programs for your team to understand the nuances of international trade regulations better. By doing so, you're positioning your business to capitalize on emerging market opportunities while minimizing compliance-related challenges.

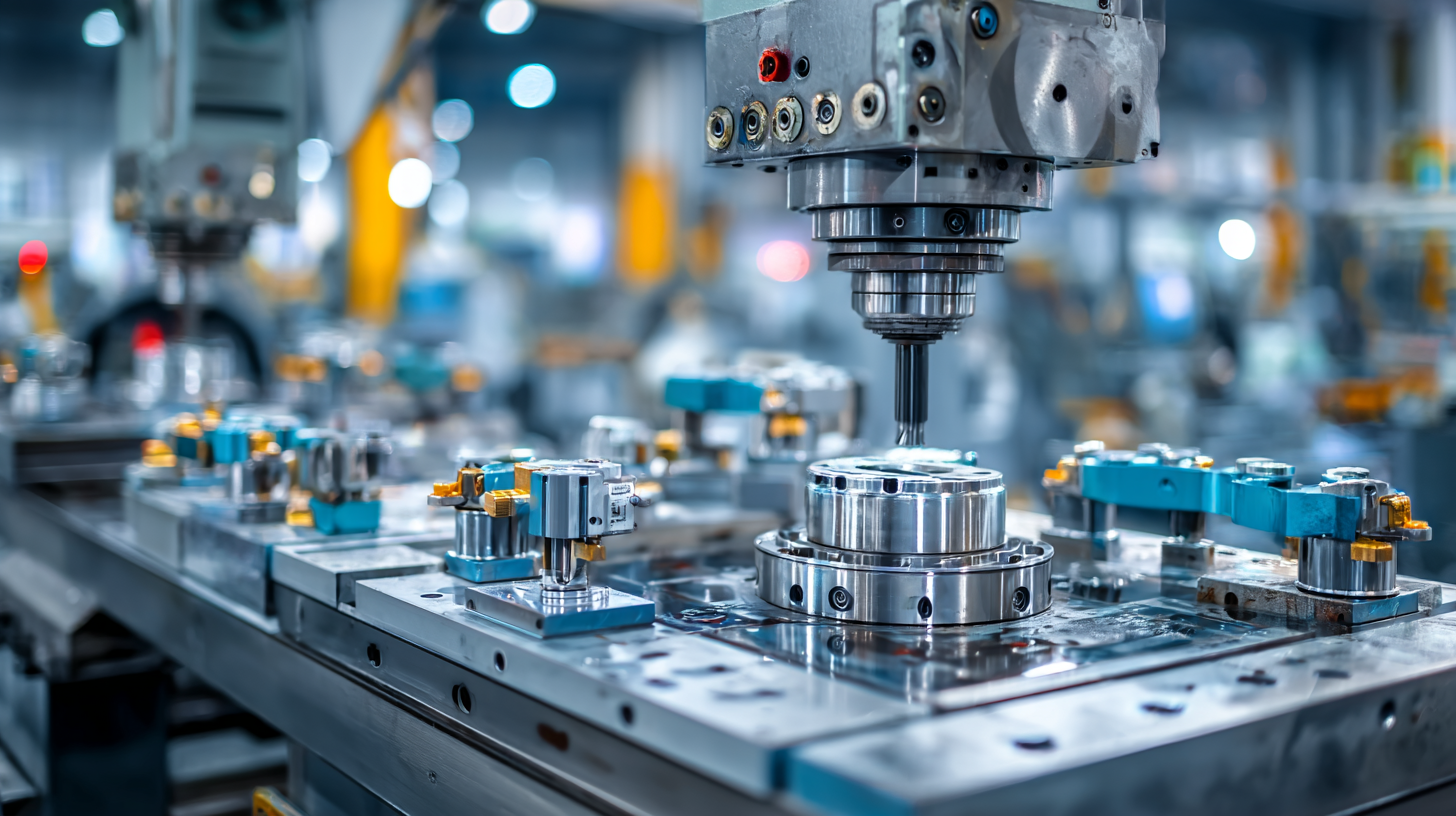

As we look ahead to 2025, several key industry trends are set to shape the landscape of CNC parts manufacturing. According to a report by Grand View Research, the global CNC machine market is expected to reach $100 billion by 2025, driven primarily by advancements in automation and smart manufacturing technologies. This shift is pushing manufacturers to adopt more sophisticated CNC parts that enhance productivity and reduce operational costs, highlighting the need for businesses to stay ahead of technological innovations.

Sustainability is another critical trend influencing the selection of CNC parts. A study by Market Research Future indicates that the demand for environmentally friendly manufacturing practices is anticipated to grow, compelling companies to seek CNC components made from recyclable materials or those that improve energy efficiency. As sustainability becomes a cornerstone of corporate strategy, the choice of CNC parts will increasingly reflect a commitment to reducing the environmental footprint, impacting not just production processes but also brand reputation and customer loyalty in a competitive market.

| Trend | Description | Impact on CNC Parts | Recommended CNC Parts |

|---|---|---|---|

| Increased Automation | Growing reliance on automated processes to enhance efficiency. | Higher demand for precision CNC components. | High-precision spindles, automated tool changers. |

| Sustainable Manufacturing | Shift towards environmentally friendly processes and materials. | Increased interest in recyclable and bio-based materials for CNC parts. | Eco-friendly lubricants, biodegradable tooling materials. |

| Smart Manufacturing | Integration of IoT and AI in manufacturing processes. | Need for CNC parts that are IoT-compatible. | Sensors, smart controllers, data analysis software. |

| Customization and Personalization | Demand for tailor-made products increases across industries. | CNC parts must support flexible and varied production runs. | Versatile CNC machines, modular tooling systems. |

| Workforce Development | Emphasis on skilled labor and ongoing training programs. | Need for CNC components that are easy to operate and maintain. | User-friendly interfaces, simplified machine setups. |

In the fast-evolving landscape of CNC manufacturing, navigating regulatory compliance is essential for maintaining competitiveness and ensuring product quality. As industries anticipate technological advancements and evolving customer demands, manufacturers must prioritize obtaining the necessary certifications. Key certifications, such as ISO 9001, ensure that companies adhere to international quality management standards, which can significantly enhance customer trust and open new market opportunities.

Moreover, understanding industry-specific certifications can further bolster a manufacturer's credibility. For example, obtaining AS9100 certification is crucial for businesses involved in aerospace applications, ensuring strict adherence to quality demands in this highly regulated sector. Similarly, FDA compliance is paramount for manufacturers producing CNC parts for medical devices, emphasizing the need for precise tolerances and reliability. As we move toward 2025, embracing these certifications will not only mitigate risks associated with non-compliance but also position manufacturers as leaders in quality and innovation within their respective industries.

In the rapidly evolving landscape of CNC machining, understanding the impact of certifications on part quality and performance is crucial for industrial success. Certifications serve as benchmarks that ensure compliance with industry standards and regulations. They not only validate the manufacturing process but also enhance customer trust by demonstrating a commitment to quality. As industries gear up for the trends of 2025, the role of certifications cannot be overstated; they often dictate the competitive edge a company can attain.

Moreover, the cost evaluation of machining per part underscores the importance of selecting certified CNC parts. Various factors, such as setup costs, tool utilization, and machinery amortization, all play a vital role in determining the overall efficiency and cost-effectiveness of the machining process. Choosing components backed by certifications can mitigate risks associated with non-compliance and poor quality, leading to more reliable performance and potentially lower costs in the long run. As we navigate future advancements, prioritizing certified options will be key to achieving both operational excellence and sustainable growth in the industry.

In the fast-evolving landscape of CNC machining, ensuring that your supply chain is future-proof is critical. One of the cornerstones of a resilient supply chain is effective management of certification documentation. As industries strive to adhere to stringent regulations and quality standards, maintaining accurate and accessible documentation is paramount. Companies should adopt a centralized digital system for managing certification records, which not only streamlines access but also helps in quick compliance checks during audits. This proactive approach can greatly reduce downtimes and operational hiccups when sourcing CNC parts.

Another best practice is to regularly review and update certification requirements in alignment with industry trends. As we approach 2025, technologies like automation and IoT are reshaping the CNC landscape, prompting shifts in quality criteria and supplier standards. Industry players must stay ahead by investing in technology that facilitates real-time monitoring and documentation management. By fostering strong relationships with suppliers and encouraging transparency, businesses can ensure that they not only meet current standards but also adapt seamlessly to future changes in the market.