Choosing the right casting parts for your project is crucial. The right components can enhance functionality and durability. However, the process can be daunting. Many factors must be considered.

Casting parts come in various materials and styles. Each option has its own advantages and disadvantages. For example, aluminum casting is lightweight yet strong. On the other hand, iron casting offers excellent wear resistance. Knowing the intended use of your project helps narrow down your choices.

It’s also important to reflect on your budget. High-quality casting parts may cost more upfront. However, they can save money in the long run by reducing maintenance needs. Ultimately, selecting the right casting parts requires careful thought and research. Taking the time to explore various options will lead to better outcomes.

When selecting casting parts, understanding materials is crucial. There are several casting materials available, each with unique properties. Aluminum is lightweight and resistant to corrosion. It covers a broad range of applications, with nearly 40% of the casting market. Notably, it excels in producing complex shapes and intricate designs.

Steel casting is another significant option. It is known for its strength and durability. It often accounts for around 30% of the market share. This material is suitable for heavy-duty applications. However, it can also lead to longer production times due to its density. Cast iron is favored for its excellent wear resistance and machinability. It serves well in automotive and industrial applications.

Despite these advantages, choosing the wrong material can lead to issues. Miscalculating thermal expansion can cause cracking. Many reports indicate that 20% of casting failures arise from material selection errors. It’s crucial to weigh the application requirements against the material properties. Understanding these factors can significantly impact project outcomes.

When evaluating project requirements for casting parts, it's crucial to consider material properties. Different materials offer various strengths, durability, and costs. According to industry reports, aluminum casts are known for their lightweight traits but may lack the strength of steel. This can impact the end product's performance.

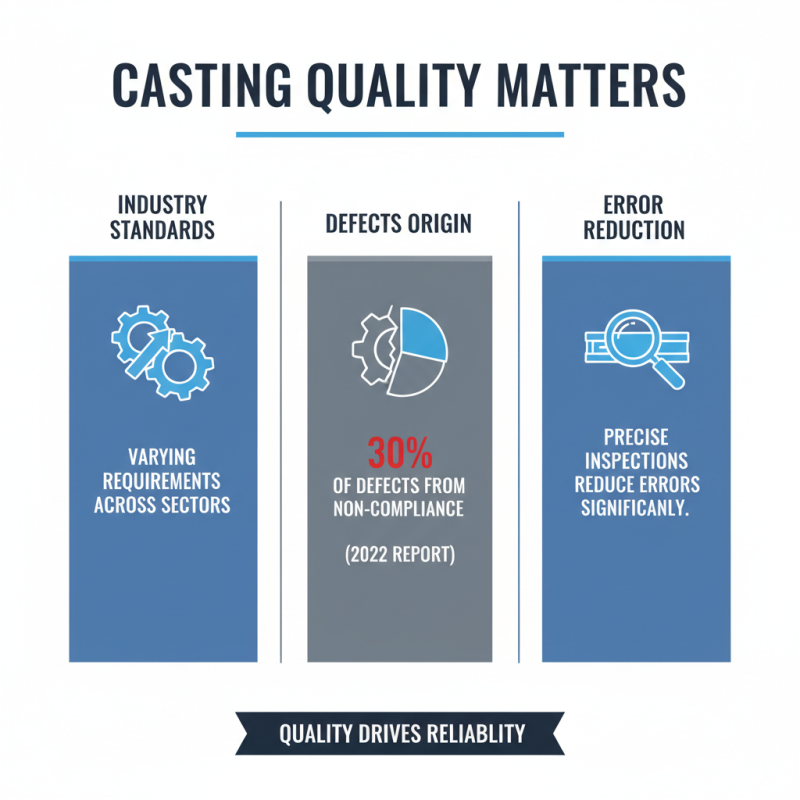

Size and complexity of your design should also be analyzed. Complex geometries may require advanced casting techniques, increasing production time and costs. A survey from the Casting Industry Association revealed that 30% of manufacturers face challenges with intricate designs in casting. Rethink your designs to streamline the casting process.

Lastly, consider the environment in which the assembled part will function. Factors such as temperature and exposure to chemicals can dictate the choice of material. Ignoring these conditions can lead to failures and higher operational costs. Strive to make informed choices throughout the design process.

When selecting casting parts, understanding quality standards is essential. Different industries have varying requirements that influence the casting process. According to a 2022 industry report, nearly 30% of casting defects stem from non-compliance with quality standards. Yet, precise inspections can reduce these errors significantly.

Tip: Always request quality assurance documentation from your supplier. This can clarify their adherence to standards.

The ASTM (American Society for Testing and Materials) outlines several criteria, such as dimensional accuracy and material properties. A casting with poor dimensional control can produce costly machine downtimes. Reports suggest that tolerances should ideally remain within ±0.5%.

Tip: Consider the expected working conditions of your project. This will determine the material and process best suited for durability.

Each casting method has its pros and cons. For example, sand casting might offer flexibility but often results in surface roughness. Reflecting upon these imperfections can lead to better decisions in future projects. As casting technology advances, staying informed on quality standards becomes vital.

Researching suppliers and manufacturers for casting parts is crucial for project success. A thorough search can uncover various options. Start by identifying local manufacturers. They often provide quicker service and easier communication. Reach out to industry networks or forums. Personal recommendations can lead to hidden gems.

Check the credibility of each supplier. Look for reviews and testimonials. They reveal experiences of previous clients. Ensure the manufacturer specializes in the type of casting you need. Not all providers are equipped for every project. Ask for samples. This will help you gauge quality.

Tips: Consider the production capacity of your chosen supplier. Make sure they can meet your deadlines. Another suggestion is to compare quotes. The best price doesn’t always mean quality. Reflect on your choices. If something feels off, trust your instincts. Finding the right partner takes time and effort.

| Casting Material | Common Applications | Benefits | Considerations |

|---|---|---|---|

| Aluminum | Automotive, Aerospace | Lightweight, Corrosion Resistant | Higher production costs compared to iron |

| Steel | Construction, Machinery | High strength, Durability | Heavier, Prone to corrosion without coating |

| Iron | Pipelines, Engine Blocks | Excellent castability, Cost-effective | Brittle, Heavier than aluminum |

| Copper | Electrical Components, Marine Applications | Excellent conductivity, Corrosion resistance | Higher cost, Weighs more than aluminum |

| Magnesium | Aerospace, Automotive | Very lightweight, High strength-to-weight ratio | Lower ductility, Requires special handling |

Budgeting for casting components requires careful planning. Costs can vary widely based on material choice, size, and complexity. For example, aluminum casts might be cheaper compared to bronze, yet durability can differ. It’s essential to consider not only the initial price but also long-term performance.

Contingency funds are crucial. Unexpected expenses often arise in projects. For instance, additional modifications might be necessary after the initial casting. Always leave room in your budget for these surprises. A 10-15% cushion is reasonable. Using precise specifications can reduce errors. However, imperfect communication can lead to costly adjustments. Reflecting on past projects can help estimate costs more accurately. Each component plays a role, no matter how small. High-quality parts can save money over time.