In the world of Steel Investment Casting, choosing the right process is crucial. Expert John Smith, a renowned authority in casting technologies, once stated, "The right process can make or break your project." This emphasizes the importance of understanding various casting methods.

Steel Investment Casting offers flexibility and precision. It is often used in industries like aerospace and automotive. However, selecting the best approach requires careful consideration. Factors like cost, lead time, and product complexity play a role. Ignoring these elements may lead to production delays.

Many newcomers to Steel Investment Casting overlook vital details. They might focus solely on pricing instead of quality. This can result in a disappointing final product. Understanding the nuances of each casting process is essential. As John Smith noted, it’s about making informed decisions that align with project goals.

Investment casting is a precise method for creating complex steel parts. This technique involves pouring molten metal into a mold. The mold is typically made of a ceramic material, which can withstand high temperatures. The process allows for fine details and excellent surface finishes.

Understanding the basics of steel investment casting is crucial. The initial step involves creating a wax model of the desired part. This model is coated with ceramic to form a shell. Once the shell hardens, the wax is melted and drained away. This leaves a cavity that matches the original shape. However, achieving the perfect shell can be challenging. If the shell is too thin, it may crack. If it's too thick, it can lead to casting defects.

Factors such as temperature control and cooling rates play a significant role. Steel must be heated to precise levels before pouring. If the temperature is incorrect, defects can occur. Practicing this method requires patience and attention. Sometimes, even experienced manufacturers encounter issues. Continuous reflection on processes can lead to improvements.

| Casting Method | Advantages | Disadvantages | Best Use Cases |

|---|---|---|---|

| Traditional Investment Casting | High precision and excellent surface finish | Long lead times and higher costs | Complex shapes and low to medium volume production |

| Vacuum Investment Casting | Minimizes inclusions and improves mechanical properties | More expensive setup and process | Aerospace components and critical applications |

| Centrifugal Casting | Good for cylindrical shapes and high-density products | Limited to specific shapes and sizes | Pipes, tubes, and other round steel products |

| Shell Molding Casting | Outstanding dimensional accuracy and surface finish | Limited to smaller parts | Small parts with intricate details |

When selecting a steel investment casting process, consider several key factors.

Material properties are crucial.

The type of steel being used can influence durability. Different steel grades offer various strengths,

corrosion resistance, and thermal properties. Understanding the end use of the component also guides material selection.

The complexity of the design matters significantly. Intricate designs may require specialized molds and processes.

It’s vital to assess whether the design is feasible for casting. Sometimes, designs need to be simplified for effective production.

This can lead to compromises in aesthetic appeal, but it’s often necessary for functionality.

Another factor is production volume. High-volume production may benefit from automated processes.

In contrast, smaller batches could warrant hand-finished casting. The choice between these options reflects on

cost efficiency and lead time.

Balancing quality with budget constraints can be challenging. Reflecting on these aspects can help refine decisions.

Making the right choice isn’t always straightforward, and that’s okay.

When selecting the right steel investment casting process, various techniques come into play. Each method has unique benefits and drawbacks. For instance, the traditional lost-wax casting offers high precision, making it ideal for intricate designs. However, it can be costly and time-consuming. The meticulous work required raises questions about efficiency.

Another technique is ceramic shell casting. This method allows for larger components. It provides good surface finish and excellent dimensional control. However, the initial setup can be expensive and complex. Many find it challenging to balance cost with quality in every project.

Lastly, there's the sand casting option, known for flexibility and lower costs. Sand casting is suitable for large quantities. Yet, surface finish might not meet high standards. One must evaluate whether trade-offs align with project goals. The choice of technique can significantly affect both timeframes and costs, requiring thoughtful consideration.

When evaluating the cost-effectiveness of steel investment casting methods, consider various factors. One key aspect is the initial setup cost. High precision requires advanced molds, which can be expensive. Analyze how this affects your overall budget.

Tips: Remember that cheaper processes may result in lower quality. Evaluate the long-term savings of using higher-quality methods. Quality defects can lead to more expenses later.

Another factor is production volume. If you're producing large quantities, investment casting can be cost-effective. However, for small runs, the upfront costs might outweigh benefits. Measure your projected needs carefully.

Tips: Think about flexibility. Some methods allow for rapid changes in design. This can save time and money if adjustments are necessary. Calculate the potential costs of modifications for different processes.

Raw material prices also play a crucial role. Fluctuations can impact your budget significantly. Always keep an eye on the market for steel prices. Your choice of steel can also affect durability and performance. Reflect on what you truly need in the end product.

This chart compares the cost-effectiveness of different steel investment casting processes based on their production volume and cost per unit. The data is based on industry standards and practices.

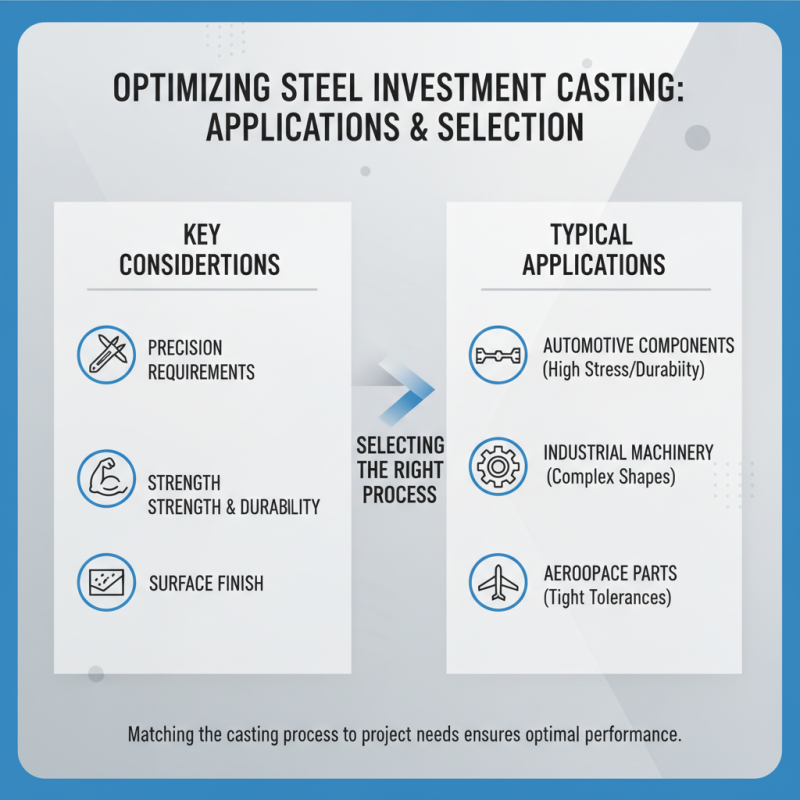

When considering the right steel investment casting process, it’s essential to analyze the potential applications for cast steel parts. Different projects might require varying degrees of precision, strength, and surface finish. For instance, automotive components often demand high strength and durability. These parts endure significant stress, making the selection of the casting method critical.

Another example is in energy sectors. Here, components must withstand extreme conditions. The choice of casting can impact not only functionality but also safety. A poorly chosen process can lead to premature failure. Engineers must reflect on design requirements and operating environments. There are many factors to weigh, including temperature extremes and corrosive materials.

Sometimes, it’s easy to overlook specifics. What might work for one industry may not suit another. Revisiting design criteria is vital to avoid issues later. Testing prototypes or using simulations can reveal unexpected flaws before full-scale production. The right process should align with the intended use and performance expectations. This careful analysis ultimately leads to more reliable and effective steel cast parts.