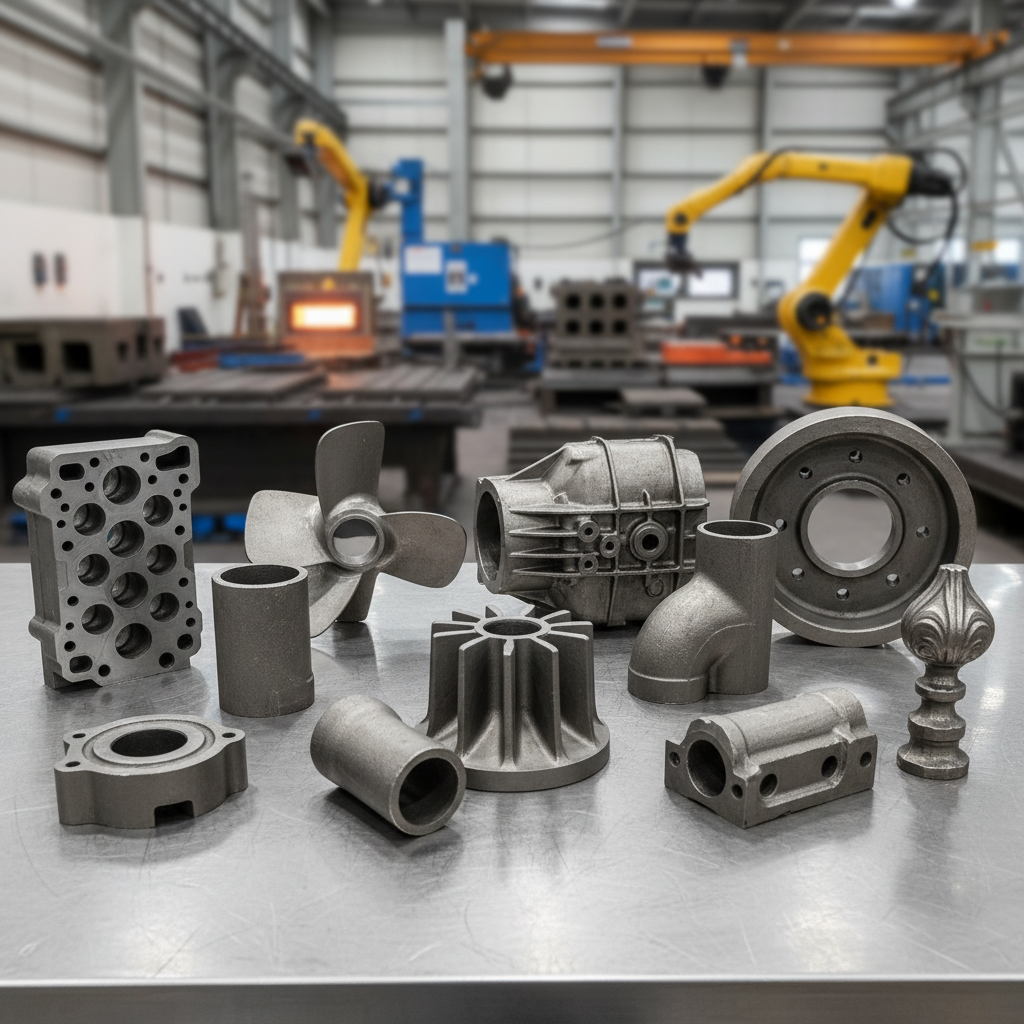

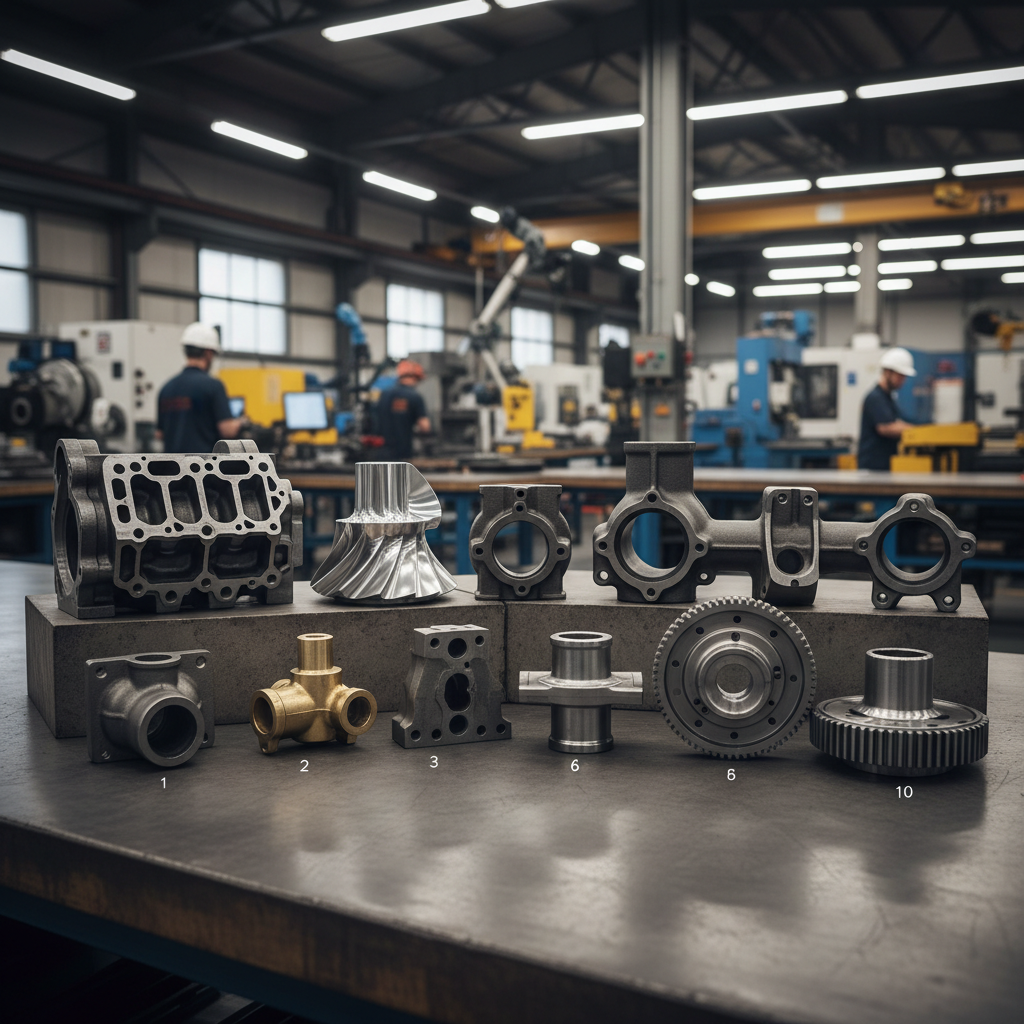

The manufacturing industry heavily relies on various components to ensure efficiency and quality, among which

casting parts play a pivotal role. According to a 2023 report by

MarketsandMarkets, the global casting parts market is projected to reach

USD 226 billion by 2026, growing at a CAGR of 5.1%. As industries ranging

from automotive to aerospace increasingly prioritize reliability and performance, understanding the

essential casting parts becomes paramount for manufacturers aiming for perfection in production.

Expert John Smith, a leading authority in the casting industry, emphasizes the significance

of mastering these components: "The key to optimal manufacturing lies in

the precision and quality of casting parts. They are not merely components but the backbone of any industrial product."

With the various types of casting processes available, including sand, investment, and die casting, each has

its unique set of advantages that cater to specific manufacturing needs. This article will explore the

top 10 essential casting parts that every manufacturer must know to

enhance their production capabilities and achieve exceptional results.

In the realm of manufacturing, casting is a pivotal process that shapes the foundation for many industrial applications. Understanding the core components involved in casting is essential for achieving optimal results. A report by the National Institute of Standards and Technology indicates that the quality of casting directly impacts the mechanical properties of the finished product, which affects approximately 70% of the cost-effectiveness in production lines. This highlights the importance of selecting the right materials and ensuring precision in the casting process.

Core components, including molds, cores, and gating systems, play a crucial role in determining the efficiency and quality of casting operations. For instance, the American Foundry Society emphasizes that the design of gating systems can influence metal flow and temperature control, crucial for minimizing defects. Moreover, investing in high-quality cores can reduce the likelihood of scrap rates by over 20%, as better core integrity leads to improved dimensional accuracy. Therefore, manufacturers must prioritize understanding and optimizing these essential casting parts to enhance the overall performance and reliability of their products.

The selection of casting materials plays a crucial role in manufacturing processes across various industries, and several key factors influence this decision. According to a recent report by the American Foundry Society, approximately 70% of foundries consider material properties, including strength, ductility, and resistance to wear, as primary criteria when selecting casting materials. For instance, metals such as aluminum and bronze are favored in applications requiring lightweight yet durable components, while cast iron remains a staple for its excellent machinability and cost-effectiveness.

Another critical factor is the environmental impact of the materials used. The global push towards sustainability is shaping material selection, driving the use of recycled and eco-friendly options. The International Aluminum Institute reports that recycling aluminum saves more than 90% of the energy required to produce new aluminum, highlighting the economic and ecological benefits of selecting recycled materials. Additionally, advancements in casting technologies, such as 3D printing, are expanding the range of materials available, enabling manufacturers to choose materials that enhance product performance while adhering to sustainable practices.

In the realm of manufacturing, precision is paramount, particularly when it comes to casting parts. Essential techniques that facilitate achieving such precision include the adoption of advanced technologies like micromanufacturing and 3D printing. These methods allow for the production of increasingly smaller components with high accuracy, catering to industries where every detail matters. Automation further enhances the manufacturing process by minimizing human error, ensuring that each cast part meets stringent quality standards.

Moreover, understanding the intricacies of surface roughness is crucial, especially in complex geometries typical in sectors like dental prototyping. As manufacturers strive for flawless finishes, implementing machine learning-based approaches for predicting surface characteristics becomes essential. This not only streamlines workflow but also helps in achieving the desired aesthetic and functional outcomes in cast parts, reinforcing precision as a vital aspect of modern manufacturing practices.

When it comes to casting, understanding common defects is crucial for achieving flawless manufacturing outcomes. Among the most frequent issues faced in casting processes are

shrinkage,

porosity, and

hot tearing.

Shrinkage occurs when metal cools and contracts, potentially creating voids within the final product. To mitigate this problem, it is essential to design molds that allow for proper cooling and to use materials with a lower contraction rate.

Porosity, another prevalent issue, can result from trapped gas in the molten metal, leading to weak spots. Utilizing vacuum or low-pressure techniques during casting can significantly reduce this risk.

Furthermore, hot tearing, which happens during solidification, can often be avoided by carefully controlling the cooling rate and ensuring that the mold design accounts for the flow of the molten alloy. By simulating casting conditions and understanding the underlying mechanics, manufacturers can implement strategies to minimize these defects and enhance production quality.

In the casting manufacturing industry, maintaining high-quality standards is essential to ensure the durability and performance of the final products. According to a recent industry report by the American Foundry Society, nearly 20% of defects in cast parts can be attributed to inadequate quality control measures. Implementing best practices in quality control can significantly reduce these defects and enhance production efficiency. Regular inspections throughout the manufacturing process, including initial mold inspections and final product testing, can detect potential issues early, saving time and reducing waste.

Another crucial element is the use of advanced technologies for monitoring casting quality. The integration of artificial intelligence and machine learning algorithms into production lines has been shown to improve accuracy in detecting anomalies. A study published by the International Journal of Advanced Manufacturing Technology indicates that facilities employing such technologies report a 30% decrease in rejection rates. By focusing on these best practices, manufacturers can not only improve the quality of their cast parts but also position themselves competitively in a market that increasingly prioritizes reliability and sustainability.