Metal Part Fabrication is a critical process in industries ranging from automotive to aerospace, influencing the efficiency and quality of manufacturing. According to a report by MarketsandMarkets, the global metal fabrication market is expected to reach $23.2 billion by 2025, growing at a CAGR of 3.5%. This growth is driven by the increasing demand for precision-engineered components that meet stringent regulatory standards. To thrive in such a competitive landscape, manufacturers must adopt best practices that enhance productivity and ensure the quality of their metal parts. From selecting the right materials to optimizing fabrication techniques, every detail counts in achieving superior outcomes. In this blog, we will delve into seven essential tips for achieving the best Metal Part Fabrication, ensuring that your operations not only meet industry demands but also drive innovation and success.

The global metal fabrication market is witnessing significant shifts, driven by emerging technologies and changing consumer demands. According to a recent report by MarketsandMarkets, the metal fabrication market is projected to reach $20.70 billion by 2025, growing at a CAGR of 3.5% from 2020. This growth presents both challenges and opportunities for businesses in the industry. Companies must navigate supply chain disruptions and rising material costs, while also adapting to the increasing demand for customized and complex metal parts.

As the market evolves, automation and advanced manufacturing technologies are becoming critical competitive advantages. A survey by McKinsey found that companies that adopt automation in their fabrication processes can increase productivity by up to 30%, effectively addressing labor shortages and improving efficiency. However, the challenge lies in the initial investment and training required to implement such technologies. Businesses that can effectively balance these challenges with the opportunities presented by technological advancements will be well-positioned to thrive in the dynamic global landscape of metal fabrication.

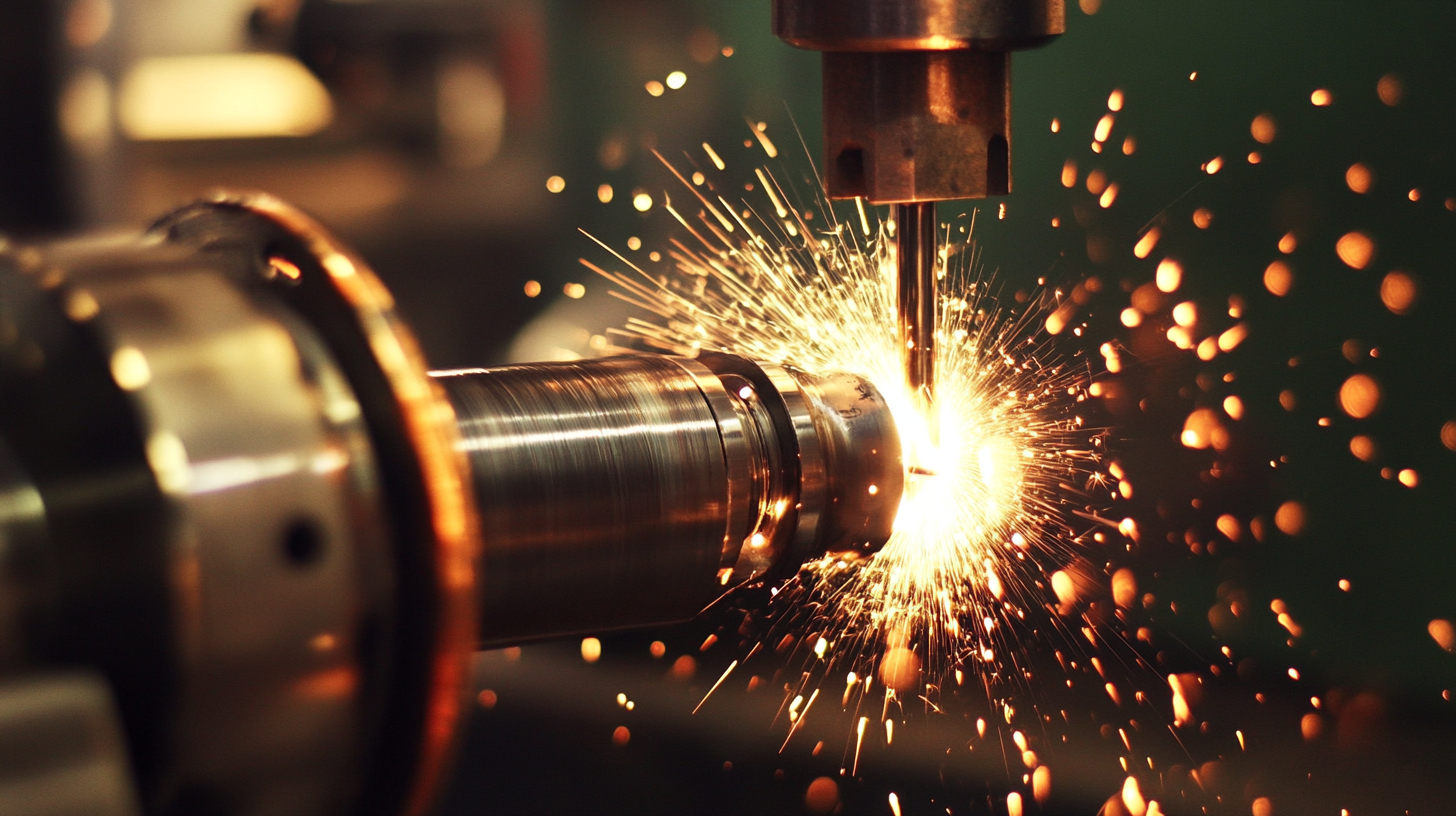

When it comes to metal part fabrication in today's competitive industries, mastering key techniques is essential for delivering high-quality products. One of the most fundamental approaches is investing in advanced machining technologies. CNC (Computer Numerical Control) machines, for instance, provide precise control over the fabricating process, enabling intricate designs and tight tolerances that manual methods struggle to achieve. Moreover, adopting automation not only boosts efficiency but also minimizes the risk of human error, resulting in consistently superior parts.

Another critical technique involves selecting the right materials for specific applications. Different metals display varying properties such as strength, weight, and corrosion resistance, which can drastically affect the performance and durability of the final product. Additionally, incorporating techniques like laser cutting and waterjet cutting can further enhance precision while reducing waste. By prioritizing these advanced methods and material choices, manufacturers can significantly elevate their metal fabrication processes, ensuring they remain competitive in an ever-evolving marketplace.

In today's competitive manufacturing landscape, the role of innovation and technology in metal fabrication is becoming increasingly vital for quality improvement. According to a report by MarketsandMarkets, the global metal fabrication market is projected to reach $20 billion by 2025, driven in large part by advancements in automation and robotics. These technologies are not only streamlining production processes but also enhancing precision, which is crucial in sectors like aerospace and automotive, where tolerances are tight and quality standards are high.

Moreover, digital fabrication technologies, such as 3D printing and computer numerical control (CNC) machining, have revolutionized the way metal parts are produced. A study conducted by Deloitte highlights that companies leveraging these technologies can achieve an up to 40% reduction in production lead time. This efficiency not only translates to faster turnaround times but also enhances the overall quality of the final product by allowing for more complex designs that were previously unfeasible. Embracing these innovations is essential for manufacturers looking to not only meet but exceed industry standards and customer expectations in metal part fabrication.

In today's complex global supply chains, the importance of quality control and standards cannot be overstated. Ensuring compliance with rigorous standards is crucial for manufacturers, particularly in the metal fabrication industry, where precision and reliability directly impact product performance. A recent report highlights that over 70% of companies sourcing components internationally have faced significant challenges related to compliance and quality assurance, underscoring the need for extensive due diligence in supplier networks. This includes evaluating providers’ adherence to sustainable practices and respect for human rights, which are increasingly becoming prerequisites for business partnerships.

Moreover, technologies such as blockchain are revolutionizing supply chain transparency and traceability. A study indicates that 92% of leaders in the manufacturing sector are investing in enhanced visibility solutions to better manage their supply chains. This shift not only bolsters operational efficiency but also aligns with the growing consumer demand for ethically sourced and responsibly produced goods. Emphasizing quality control and compliance not only mitigates risks but also fosters long-term sustainability, essential for thriving in an evolving marketplace.

| Tip # | Tip Description | Importance | Quality Control Method |

|---|---|---|---|

| 1 | Choose the Right Material | Ensures durability and functionality | Material Certification and Testing |

| 2 | Invest in Advanced Technology | Increases precision and efficiency | Regular Equipment Calibration |

| 3 | Develop a Comprehensive Design Plan | Facilitates better fabrication processes | Design Reviews and Simulations |

| 4 | Implement Strict Quality Standards | Reduces waste and increases reliability | Quality Audits and Compliance Checks |

| 5 | Train Skilled Workforce | Enhances skill level and output quality | Ongoing Training Programs |

| 6 | Utilize Efficient Supply Chain Management | Streamlines processes and reduces costs | Supplier Performance Evaluations |

| 7 | Conduct Regular Evaluations and Feedback | Improves processes through actionable insights | Post-Production Quality Reviews |

Building strong partnerships is critical for the success of international metal fabrication. In today’s competitive landscape, manufacturers are increasingly recognizing the value of strategic alliances that can help them expand their reach and enhance operational efficiency. By collaborating with trusted partners, businesses can share resources, reduce costs, and access new markets, ultimately driving innovation and growth.

To maximize these partnerships, here are a few essential tips: First, identify partners whose values and goals align with yours, ensuring a mutually beneficial relationship. Second, invest in building robust communication channels to facilitate knowledge sharing, which can help both parties navigate challenges and seize opportunities. Lastly, leverage digital tools to streamline processes and enhance collaborative efforts, as the ongoing shift towards digitalization is transforming manufacturing landscapes.

As manufacturing companies navigate the complexities of global supply chains, forming solid partnerships will not only help them remain competitive but also enable them to adapt to evolving market demands. Emphasizing collaboration and innovation is key to achieving success in international metal fabrication.