When it comes to selecting the right stainless steel casting for your project, the decision can significantly impact the performance, longevity, and functionality of the final product. Stainless steel casting is a versatile manufacturing process that allows for the creation of complex shapes with high precision, making it ideal for a variety of applications across industries. However, with numerous choices available in the market, choosing the right stainless steel casting can be challenging. Understanding the key factors that influence this decision is essential for ensuring quality and cost-effectiveness. In this blog, we will provide you with five essential tips that will guide you in making an informed choice, ensuring that your stainless steel casting meets your specific requirements and stands the test of time.

When it comes to selecting the right stainless steel casting for your project, the decision can significantly impact the performance, longevity, and functionality of the final product. Stainless steel casting is a versatile manufacturing process that allows for the creation of complex shapes with high precision, making it ideal for a variety of applications across industries. However, with numerous choices available in the market, choosing the right stainless steel casting can be challenging. Understanding the key factors that influence this decision is essential for ensuring quality and cost-effectiveness. In this blog, we will provide you with five essential tips that will guide you in making an informed choice, ensuring that your stainless steel casting meets your specific requirements and stands the test of time.

When embarking on a project that requires stainless steel casting, it is crucial to first identify your specific project requirements. Understanding the intended use of the casting will guide you toward selecting the most suitable type of stainless steel. Consider factors such as the casting's exposure to corrosion, temperature extremes, and mechanical stress. This initial assessment will help narrow down the grade of stainless steel that best meets the demands of your project.

When embarking on a project that requires stainless steel casting, it is crucial to first identify your specific project requirements. Understanding the intended use of the casting will guide you toward selecting the most suitable type of stainless steel. Consider factors such as the casting's exposure to corrosion, temperature extremes, and mechanical stress. This initial assessment will help narrow down the grade of stainless steel that best meets the demands of your project.

One essential tip is to evaluate the environment in which the stainless steel casting will operate. For example, if your project involves a marine environment, look for stainless steel grades with higher corrosion resistance, such as 316 stainless steel. Additionally, consider the casting process itself; different methods like sand casting or investment casting may yield different results in terms of precision and finish. Selecting the appropriate casting technique is just as vital as choosing the right material.

Lastly, don’t underestimate the importance of working with experienced suppliers who can offer insights based on your requirements. A knowledgeable supplier can assist you in selecting the right grade and fabrication method, ensuring that the final product not only meets your project specifications but also adheres to any industry standards. By taking these steps, you can ensure a successful outcome for your stainless steel casting needs.

When it comes to choosing the right stainless steel for casting applications, understanding the different grades of stainless steel is crucial. Stainless steel is renowned for its corrosion resistance and durability, making it a popular choice across various industries. The most commonly used grades include 304 and 316.

Grade 304, often referred to as 18/8 stainless steel, contains chromium and nickel, providing a balance of corrosion resistance and strength. It’s an ideal choice for applications where cleanliness is essential, such as cookware.

On the other hand, Grade 316 offers enhanced resistance to corrosion, especially in marine environments, due to the addition of molybdenum. This makes it suitable for chemical processing equipment and outdoor applications where exposure to harsh conditions is likely. When selecting stainless steel for casting, it's important to consider the specific requirements of your application, such as temperature fluctuations and exposure to corrosive substances. Ultimately, understanding these grades will help you make an informed decision, ensuring the longevity and reliability of your stainless steel products.

When evaluating stainless steel casting manufacturers, it’s essential to consider various key factors that can significantly influence the quality of your final product. Start by assessing the manufacturer's experience and expertise in stainless steel casting. A company with a long-standing reputation and a portfolio of successful projects is more likely to deliver high-quality castings that meet your specifications. Additionally, check for certifications and compliance with industry standards, as this reflects the manufacturer’s commitment to quality and safety.

Another crucial aspect is the manufacturer’s production capabilities and technology. Inquire about the equipment they use for casting and any advanced techniques they may employ that can enhance precision and reduce defects. Furthermore, don’t hesitate to ask about their quality control processes. Understanding how they monitor and ensure quality throughout the production process can give you confidence in their ability to provide reliable products. Engaging with the manufacturer during your evaluation can reveal their responsiveness and willingness to collaborate, which are vital for maintaining a strong working relationship.

When it comes to stainless steel castings, the decision often boils down to a crucial balance between cost and quality. Choosing the right casting is not just about selecting the cheapest option available; it's about understanding the impact of material quality on the final product. High-quality stainless steel castings offer better durability, corrosion resistance, and can ultimately lead to long-term savings by minimizing maintenance and replacement costs. Therefore, manufacturers should weigh the short-term savings of lower-cost castings against the potential long-term implications of inferior quality.

Investing in quality stainless steel castings pays off in various ways. For instance, better quality materials can improve the performance and lifespan of components, especially in demanding environments. Conducting thorough research on suppliers and seeking recommendations can help ascertain a provider's reputation for quality. While it may be tempting to choose a provider based solely on price, a more informed approach will prioritize material specifications, manufacturing processes, and after-sales support, ensuring that the casting not only meets budgetary constraints but also aligns with the overall operational needs and durability expectations of the project.

| Tip | Description | Cost Factor | Quality Indicator |

|---|---|---|---|

| Material Grade | Choose the correct stainless steel grade for your application. | Higher grade costs may increase overall casting cost. | Higher grades offer better corrosion resistance and durability. |

| Design Complexity | Consider the complexity of your design, which can affect casting costs. | More complex designs can increase production costs. | Complex designs may require higher skill levels or technology, indicating better quality. |

| Production Volume | Assess your expected production volume for cost-effectiveness. | Higher volumes typically reduce unit costs. | Higher production volumes can improve consistency and quality. |

| Supplier Reputation | Research potential suppliers’ track records and reviews. | Reputable suppliers may charge a premium. | Established suppliers often ensure higher quality standards. |

| Post-Casting Processes | Evaluate the need for machining, surface treatment, or finishing. | Additional processes can significantly increase costs. | Finishing processes enhance the aesthetic and functional quality. |

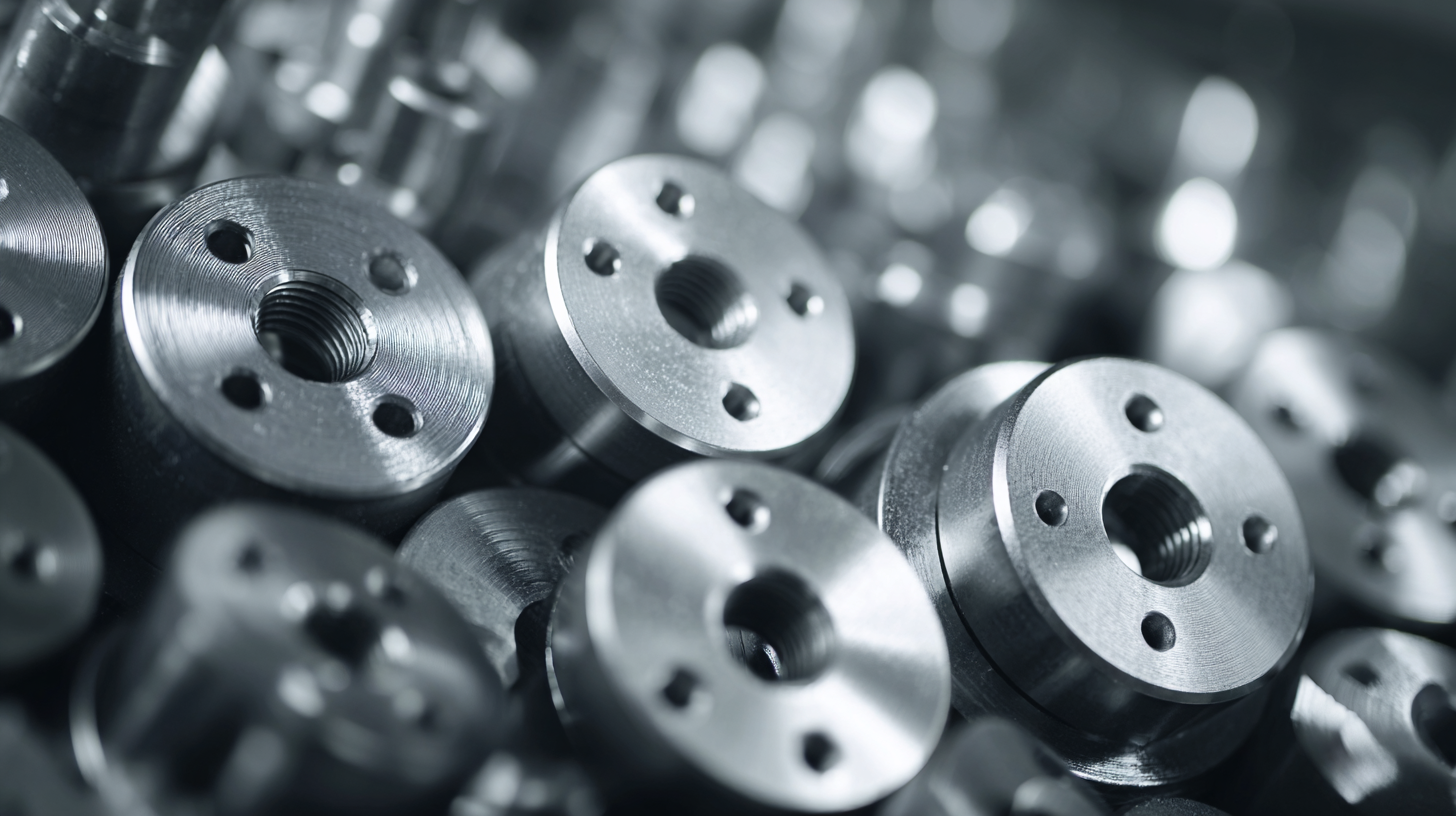

Post-casting processes play a crucial role in ensuring that stainless steel castings meet stringent quality standards and functional requirements. After the initial casting, finishing processes such as machining, surface treatment, and polishing are vital to achieve the desired surface quality and dimensional accuracy. These steps not only enhance the aesthetic appeal of the final product but also contribute significantly to its durability and performance. By paying close attention to these finishing processes, manufacturers can eliminate defects, improve corrosion resistance, and ensure that the castings meet specific engineering tolerances.

Quality control is another essential aspect of post-casting processes that cannot be overlooked. Implementing rigorous inspection protocols helps in identifying any inconsistencies or flaws early in the production cycle. Techniques such as non-destructive testing, dimensional analysis, and visual inspection are commonly employed to ensure that each piece adheres to required specifications. This commitment to quality not only saves time and resources but also builds trust with customers, ensuring that the end products perform reliably in their intended applications.