Metal Part Fabrication plays a crucial role in various industries. It transforms raw materials into precise components. Understanding key practices is essential for success.

Every project presents challenges. Poor planning or mistakes can lead to wasted materials and time. Attention to detail is vital. Proper techniques and tools make a significant difference.

Investing in training can improve skills. Learning from past errors helps avoid repeating them. Collaboration among team members fosters better outcomes. Emphasizing quality assurance ensures reliable results.

In the metal fabrication industry, efficiency and quality are paramount. Reports indicate that nearly 70% of manufacturers struggle with production delays due to inefficient processes. Streamlining operations can significantly enhance output and reduce costs. Critical elements include the optimization of workflow and machinery. Correct machine calibration plays a vital role. A misalignment can lead to wasted materials and increased rework.

Moreover, workforce skills directly impact quality. A survey revealed that 60% of quality issues stem from operator error. Training programs must be prioritized. Investing in skilled labor can yield better results in terms of precision and efficiency.

Material selection also influences fabrication success. For instance, using the right alloy can enhance durability and reduce machining time. However, many companies overlook the implications of poor material choices. This often leads to subpar final products, costing time and reputation. These sectors need continuous reflection and improvement.

Metal fabrication is a critical process in various industries. Understanding the techniques involved can lead to enhanced efficiency and product quality. Common methods include welding, cutting, and bending. Each technique has distinct advantages and applications.

Welding is a foundational technique. It joins metal pieces through heat and pressure. Reports indicate that nearly 50% of fabricated metal products use welding. The selection of the right welding method matters. Consider the types of metals, thickness, and desired strength. Think about the environment too. For instance, some methods are better for outdoor use.

Cutting techniques, including laser and plasma cutting, are gaining traction. They allow for precise shapes and details. According to industry data, laser cutting can improve efficiency by 20%. Tip: Always assess the specifics of your project. Review material thickness and tolerances before choosing a cutting method.

Bending processes are essential for creating specific angles or shapes. They can involve mechanical or hydraulic presses. Mistakes in bending can lead to wasted materials. It’s critical to plan and execute bends at the correct angle. This often requires adjustments and fine-tuning. Work closely with your team to ensure accuracy.

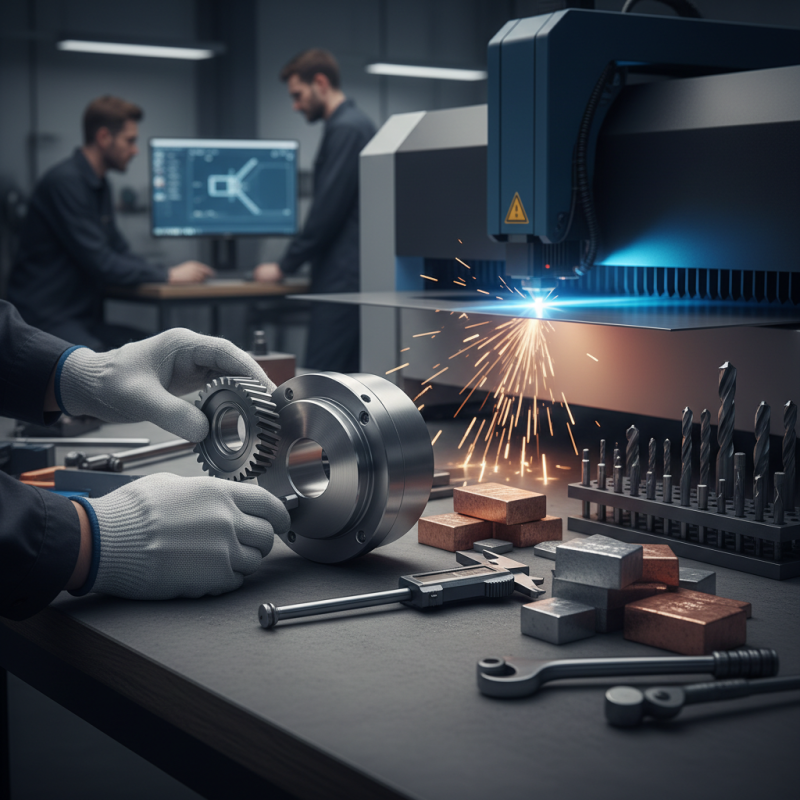

Precision metal fabrication relies heavily on the right tools and equipment. A recent industry report indicated that up to 40% of fabrication errors stem from inadequate tooling. Choosing the proper equipment can significantly reduce these mistakes. Common tools include CNC machines, laser cutters, and welding machines, which are essential for achieving accuracy.

CNC machines enhance precision and efficiency, but they require skilled operators. Many companies overlook the importance of training, leading to production setbacks. Moreover, laser cutting provides clean edges, but it comes with a steep learning curve. Equipment maintenance is also critical. Regular inspections can prevent costly downtime. A study found that 20% of small fabricators struggle with equipment reliability.

Investing in high-quality tools is important, but so is understanding their limitations. For instance, some high-tech machines may not suit every project. Fabricators need to assess their specific needs. It's crucial to balance cutting-edge technology with practical applications. Often, simpler tools can deliver better results for smaller tasks. Reflecting on these elements can lead to improved processes and outcomes in metal fabrication.

| Tool/Equipment | Purpose | Key Features | Recommended Use |

|---|---|---|---|

| CNC Machine | Precision cutting and shaping of metal parts | High accuracy, programmable control, multi-axis capabilities | For complex geometries and large production runs |

| Laser Cutter | Cutting materials with high precision | Quick setup, minimal material waste, intricate cuts | Ideal for prototyping and custom parts |

| Press Brake | Bending metal sheets | Customizable bending profiles, various tonnage options | For creating angles and complex profiles |

| Welding Machine | Joining metal pieces | Various welding methods (MIG, TIG), adjustable heat settings | For fabricating assemblies and structural components |

| Metal Shear | Cutting sheets and plates | Heavy-duty blades, precise cuts, automatic or manual operation | For high volume cutting and sheet metal processing |

In the fast-evolving field of metal fabrication, integrating advanced technologies like automation and artificial intelligence (AI) is no longer optional. A recent report from the International Federation of Robotics highlighted that global robot sales in the manufacturing sector reached approximately 384,000 units in 2022. This reflects a growing trend towards automation in fabrication processes. Automation enhances precision, reduces waste, and significantly decreases production time.

One essential tip for successful metal part fabrication is to embrace automation. Investing in automated systems can streamline operations. For instance, robotic welding can improve joint quality and reduce errors. This leads to better consistency in outputs, which is crucial in meeting customer demands.

Incorporating AI can further optimize the fabrication process. Using AI-driven analytics, companies can monitor machine performance in real time. This allows for predictive maintenance, minimizing downtime. However, some businesses struggle to adapt to these technologies. Their systems may lack the integration needed for full efficiency. Thus, continuous evaluation of your technology stack is critical. Without it, potential gains may remain untapped.

In metal fabrication, industry standards and quality control play crucial roles. Adhering to established protocols can significantly enhance the final product's integrity. According to a recent report by the Fabricators & Manufacturers Association (FMA), companies that implement stringent quality control measures can reduce defects by up to 30%. This reduction not only saves costs but also boosts customer trust.

Quality control includes regular inspections and testing throughout the fabrication process. Techniques like non-destructive testing are essential. These methods can identify potential failures early. However, even firms with robust quality systems experience occasional oversights. In fact, the National Institute of Standards and Technology (NIST) reports that human error still accounts for approximately 15% of quality failures in metal fabrication. Addressing this requires continuous training and process evaluation.

Staying updated with industry standards is vital. The ISO 9001 certification sets a benchmark for quality management. Yet, many smaller firms struggle to meet these standards due to resource constraints. The gap in achieving compliance can lead to inconsistencies. Emphasizing a culture of quality can close this gap and drive success in fabrication processes.