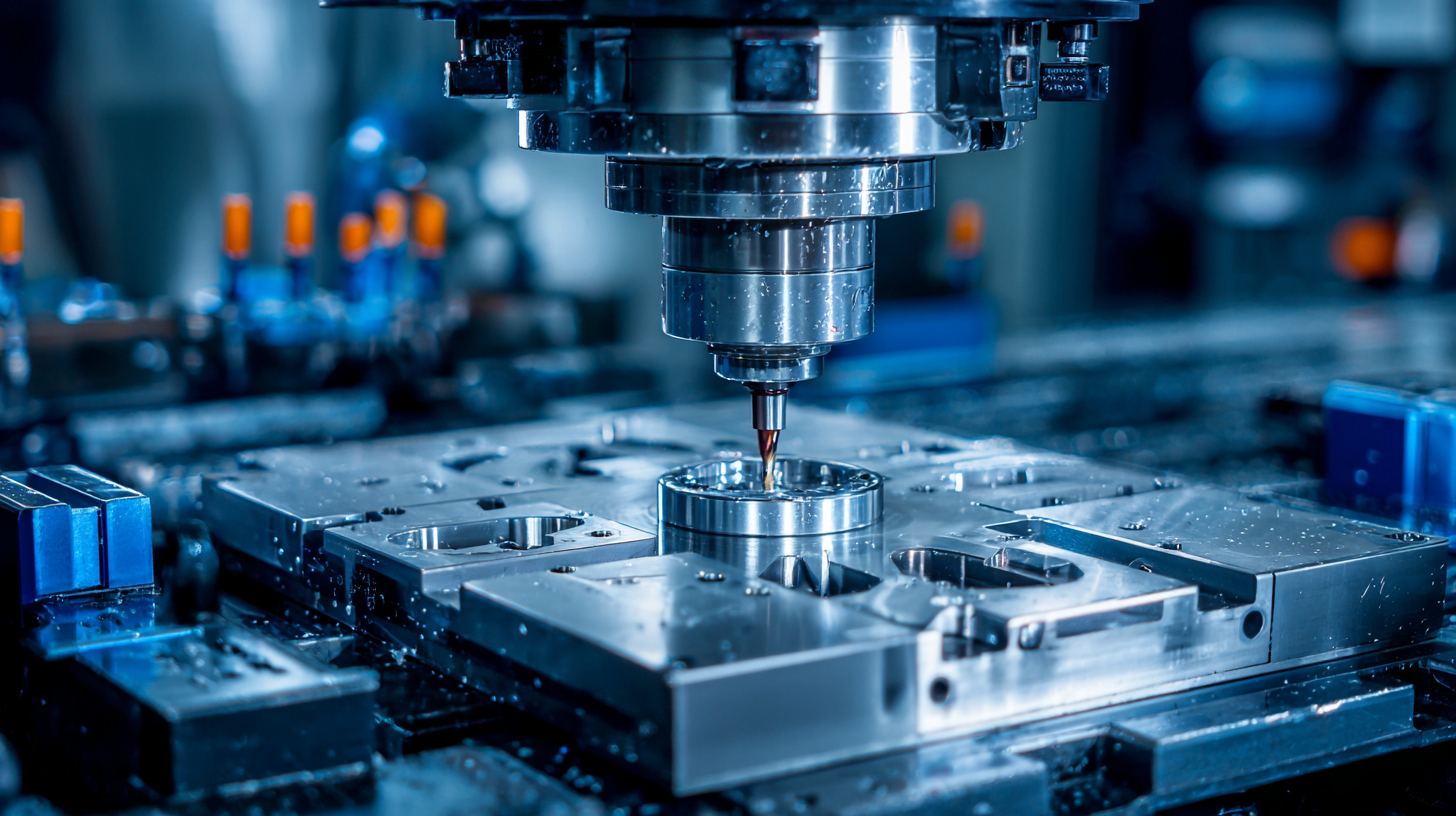

In the rapidly evolving landscape of manufacturing, the importance of streamlining processes in CNC parts production cannot be overstated. With the global CNC machining market projected to reach $100 billion by 2025, optimizing manufacturing workflows is essential for staying competitive. According to a recent industry report, effective implementation of advanced CNC technologies can enhance production efficiency by up to 30%, significantly lowering lead times and costs. This allows manufacturers to meet the increasing demand for precision-engineered components in sectors such as aerospace, automotive, and medical devices. By adopting best practices and innovative strategies, businesses can elevate their CNC parts manufacturing processes, ensuring not only higher quality but also greater adaptability in an ever-changing market. Embracing these essential tips will be crucial for organizations aiming to thrive in this competitive environment.

In CNC parts manufacturing, precision is paramount, with critical metrics playing a vital role in ensuring quality and efficiency. A fundamental aspect is the tolerances specified during the design phase, which often dictate the acceptable limits of deviation in dimensions. According to industry reports, maintaining tolerances within ±0.001 inches can significantly enhance product performance and reduce waste, making it essential to adopt rigorous quality control measures. This demands real-time data collection and analysis from the manufacturing process, allowing manufacturers to monitor deviations and implement corrective actions swiftly.

Moreover, predictive maintenance has emerged as a transformative approach to enhance manufacturing precision. Recent studies comparing deep learning models for predictive maintenance highlight the impact of sensor data in identifying potential machine failures before they occur. By leveraging advanced algorithms, manufacturers can reduce downtime by up to 30%, thereby increasing output consistency. This capability not only aligns with the growing need for operational efficiency in the face of global competition but also ensures that production aligns with precise specifications, reaffirming the significance of precision in CNC parts manufacturing.

Collectively, these practices illustrate the critical nature of precision metrics in optimizing both product quality and manufacturing processes.

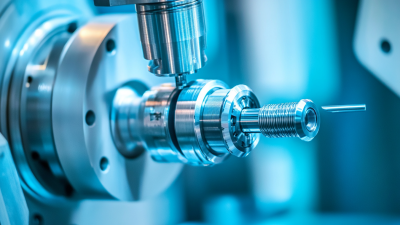

The integration of advanced technologies such as automation and robotics is revolutionizing the CNC parts manufacturing process. Automation not only enhances efficiency but also significantly improves precision, resulting in higher quality products and reduced waste. According to market analysis reports, the integrated servo motor market is projected to reach significant growth, driven by both AC and DC motors which cater to varying voltage requirements across different industries, from automotive to aerospace. This trend highlights the essential role of advanced technology in optimizing manufacturing processes and meeting the increasing demand for precise and reliable parts.

Furthermore, the shift towards automated solutions is creating new job opportunities within sectors like North Penn, where traditional manufacturing has evolved into more sophisticated environments. As factories adopt robotics, they require skilled technicians to maintain and program these systems, thereby fostering innovation and creating a demand for a workforce adept in digital technologies. Recent studies indicate that industries leveraging automation not only elevate production capabilities but also drive workforce transformation, underscoring the impact of advanced manufacturing in contemporary job creation.

As the global automotive industry pivots toward electrification and lightweighting, the selection of materials for CNC parts manufacturing takes on heightened significance. Magnesium alloys, recognized for their excellent strength-to-weight ratio, are emerging as a preferred choice in this evolving landscape. According to a report by the International Magnesium Association, magnesium can reduce vehicle weight by up to 30% compared to aluminum, which in turn enhances fuel efficiency and extends electric vehicle ranges. This strategic material selection not only improves performance but also meets stringent environmental regulations.

In the aerospace sector, where precision and efficiency are critical, the integration of advanced alloys such as titanium has been a game-changer. In particular, Ti6Al4V alloy has seen extensive use due to its excellent mechanical properties. However, traditional machining challenges, such as wear and abrasion resistance, necessitate innovative solutions. Recent studies demonstrate that cryogenic treatment of Ti6Al4V significantly improves its machinability by enhancing its hardness and reducing tool wear. Multi-objective optimization techniques, such as MOAVOA and MOGA, are increasingly being employed to refine the machining process, ultimately leading to reduced production times and improved part quality in high-stakes aerospace applications.

Implementing effective quality control measures is crucial for enhancing the CNC parts manufacturing process. One of the most effective techniques is Statistical Process Control (SPC), which utilizes statistical methods to monitor and control manufacturing processes. By measuring and analyzing the statistical variation in production, manufacturers can identify trends that may indicate potential defects before they escalate. This proactive approach allows teams to make necessary adjustments in real-time, significantly reducing waste and ensuring higher product quality.

Incorporating SPC into the manufacturing process involves establishing key performance indicators that reflect the critical aspects of production. Control charts can be employed to visualize production data, highlighting any deviations from established limits. This visualization empowers operators to react swiftly and maintain optimal performance. Additionally, regular training on SPC techniques fosters a culture of quality awareness among employees, ensuring that quality control is a shared responsibility throughout the organization. By prioritizing these methods, manufacturers can dramatically minimize defects, improve efficiency, and enhance customer satisfaction in the highly competitive CNC industry.

| Tip No. | Tip Description | Statistical Process Control Technique | Expected Outcome |

|---|---|---|---|

| 1 | Establish a clear quality plan | Control Charts | Improved defect detection |

| 2 | Train employees on quality standards | Capability Indices | Higher operational competency |

| 3 | Implement regular equipment maintenance | Pareto Analysis | Reduced machine downtime |

| 4 | Monitor process variations frequently | Histogram | Enhanced process understanding |

| 5 | Utilize feedback loops for continuous improvement | Scatter Plots | Greater insight into correlations |

| 6 | Incorporate supplier quality assessments | Control Charts | Improved supplier quality |

| 7 | Regularly review and update quality processes | Root Cause Analysis | Sustainable quality improvements |

Sustainability in CNC manufacturing has become a critical focus as industries seek to minimize their ecological footprint. By integrating sustainable practices, manufacturers can effectively reduce waste and energy consumption, resulting in both environmental benefits and potential cost savings. According to a report by the World Economic Forum, the manufacturing sector is responsible for approximately 20% of global energy consumption, highlighting the urgent need for improvement in this area.

One of the essential tips to reduce waste is to optimize your production processes through advanced CNC programming and automation. By utilizing software that ensures precision and efficiency, manufacturers can decrease scrap rates significantly. The National Institute of Standards and Technology reported that optimized machining processes can reduce material waste by up to 30%, driving both sustainability and profitability.

Another key approach is to incorporate energy-efficient machinery and renewable energy sources in your production facilities. Switching to equipment that meets or exceeds Energy Star specifications can lower energy usage dramatically. The U.S. Department of Energy estimates that energy-efficient technologies can lead to energy savings of 10-30%, making a substantial impact on overall resource consumption in CNC operations. Implementing these strategies not only supports a greener future but also positions manufacturers as leaders in sustainability within the industry.