When embarking on a project that requires Stainless Steel Parts, choosing the right components can be challenging. Expert David Thorne, a recognized figure in the stainless steel industry, once said, "Quality and precision are key when selecting parts." His insight encapsulates the essence of making informed choices.

The world of Stainless Steel Parts is vast and varied. Each project has unique requirements that affect the selection process. Factors include the part's intended use, the environment it will face, and budget constraints. Many forget to consider how different grades of stainless steel influence durability and performance.

Many users face unanticipated issues during their selection process. They might overlook the compatibility of parts or the specifications required for optimal performance. Understanding these nuances can prevent costly mistakes. It's essential to reflect on what you need from Stainless Steel Parts to avoid future complications.

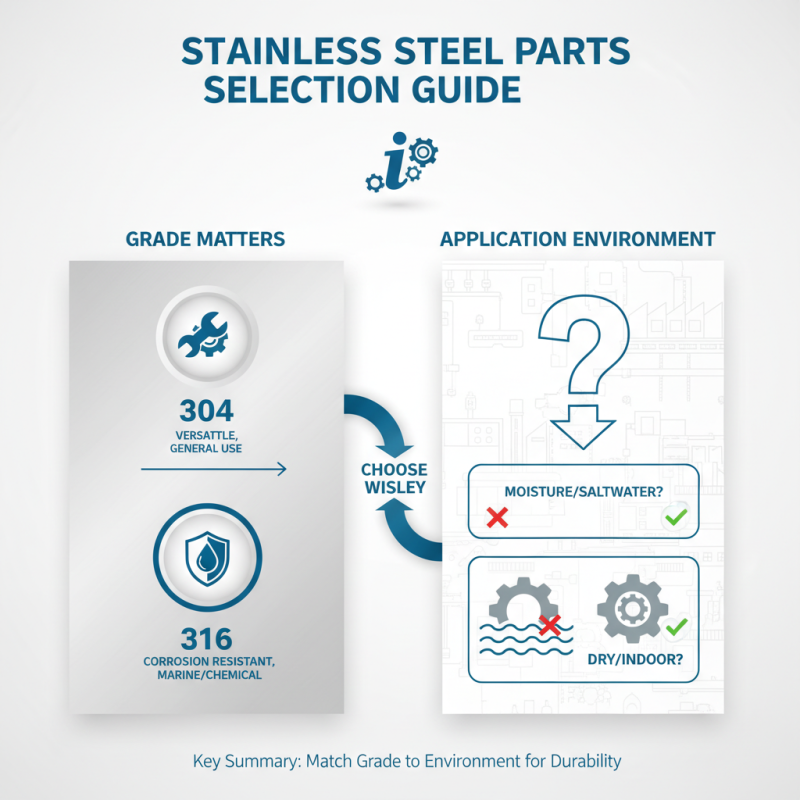

Stainless steel alloys come in various types, each with distinct characteristics. Understanding these differences is crucial for selecting the right parts for your project. For example, 304 stainless steel is known for its excellent corrosion resistance. It is often used in kitchen appliances. However, it might not be suitable for marine environments. That’s where 316 stainless steel shines, offering better protection against saltwater.

Another option is 430 stainless steel, which is magnetic and less expensive. It’s often found in home appliances. However, its corrosion resistance is not as robust as 304 or 316 grades. If you need a part that can handle heat, look into stainless steel alloys like 321. They maintain strength at high temperatures but can be more challenging to source. Choosing the right alloy depends on the specific demands of your project.

When selecting stainless steel parts, several factors demand attention. The grade of stainless steel matters. Different grades have unique properties. For example, 304 is versatile, while 316 offers better corrosion resistance. Consider where the parts will be used. Will they face moisture? If so, a higher grade may be essential.

Cost is another consideration. Stainless steel can be expensive. Sometimes, it’s tempting to choose cheaper alternatives. This could lead to issues down the road. Think about the long-term benefits of investing in higher quality. Reflect on the project's requirements. Do the parts need to withstand extreme temperatures? This may restrict your options further.

Another critical aspect is the finish of the parts. A polished surface might appeal visually but can alter performance. Look into how the finish impacts functionality. Additionally, sizing and dimensions are crucial. A minor miscalculation can derail your project. Always double-check your measurements before making a decision.

When evaluating the cost and availability of stainless steel options, several factors come into play. Stainless steel is widely used across various industries, valued for its durability and corrosion resistance. The price can fluctuate based on type, grade, and market demand. According to industry reports, the cost of stainless steel has seen a rise of approximately 15% over the past year, affecting procurement strategies.

Availability is another critical aspect. Many suppliers face challenges in sourcing specific grades due to raw material shortages. The global pandemic significantly disrupted the supply chain, leading to delays. Inventory levels have not fully recovered, impacting project timelines. It’s essential to consider local suppliers versus international ones, as shipping costs can affect overall budgeting.

Investing more upfront might seem unappealing. However, cheaper options frequently result in quality compromises. With stainless steel, durability often translates to long-term savings. Selecting the wrong grade can lead to increased maintenance costs later. This imbalance highlights the need for careful assessment of both immediate costs and future needs.

When selecting stainless steel parts, performance and durability are critical. Stainless steel offers corrosion resistance, but not all types are equal. Assess the specific environment the parts will face. For example, marine applications require higher resistance to saltwater corrosion. Consider the grade of stainless steel. For instance, 304 is common, but 316 stands out for harsher conditions.

It's essential to evaluate the manufacturing process. Poor techniques can lead to defects that compromise durability. Look for parts with consistent finishes. Surface quality matters; rough surfaces may trap contaminants. However, aesthetic appeal shouldn't dominate your decision. Functionality often prevails over looks.

Many overlook maintenance. Even durable stainless steel corroded in the long run if neglected. Regular cleaning can prolong life. Think about the application. Whether for construction or small machinery, every project has unique needs. Misjudgments can be costly. Understanding the specific requirements is vital for successful outcomes.

When sourcing stainless steel parts, safety is paramount. Understand the specifications that meet your project’s requirements. According to industry reports, over 30% of sourcing failures arise from incorrect material selection. It's critical to review the certification of the stainless steel you plan to buy. Look for compliance with standards such as ASTM or ISO. These certifications assure quality and durability.

Pricing is often a reflection of quality in the stainless steel market. Research suggests that many buyers overlook the importance of supplier reputation. Selecting a supplier with a strong track record can significantly reduce risks. Scams do occur, with counterfeit materials infiltrating the market. Always request documentation to verify the supplier's claims. Also, consider small batch testing before placing larger orders. This step may cost more upfront but can save money in the long run.

Communication with your supplier is essential. Be clear about your specifications and expectations. Many misunderstandings arise due to vague descriptions. A staggering 25% of project delays stem from miscommunication. Establishing a strong dialogue ensures both parties align on quality needs. This may lead to revisions in your order and delays, but it fosters better long-term partnerships.