In the rapidly evolving landscape of modern manufacturing, the significance of high-quality CNC parts cannot be overstated. As industries increasingly rely on precision engineering, reports indicate that companies utilizing advanced CNC machinery can enhance production efficiency by up to 30%, while reducing operational costs by nearly 20%. The importance of maintaining optimal functionality through effective after-sales support and minimized repair costs becomes paramount. A 2022 industry survey revealed that nearly 60% of manufacturers prioritize the longevity and reliability of CNC parts, underscoring their critical role in sustaining production lines.

Strong after-sales service is essential not only for troubleshooting and repairs but also for ensuring that businesses maximize the return on investment from their CNC systems. Therefore, understanding the intricate connection between CNC parts and service efficiency is vital for companies striving to remain competitive in today's market.

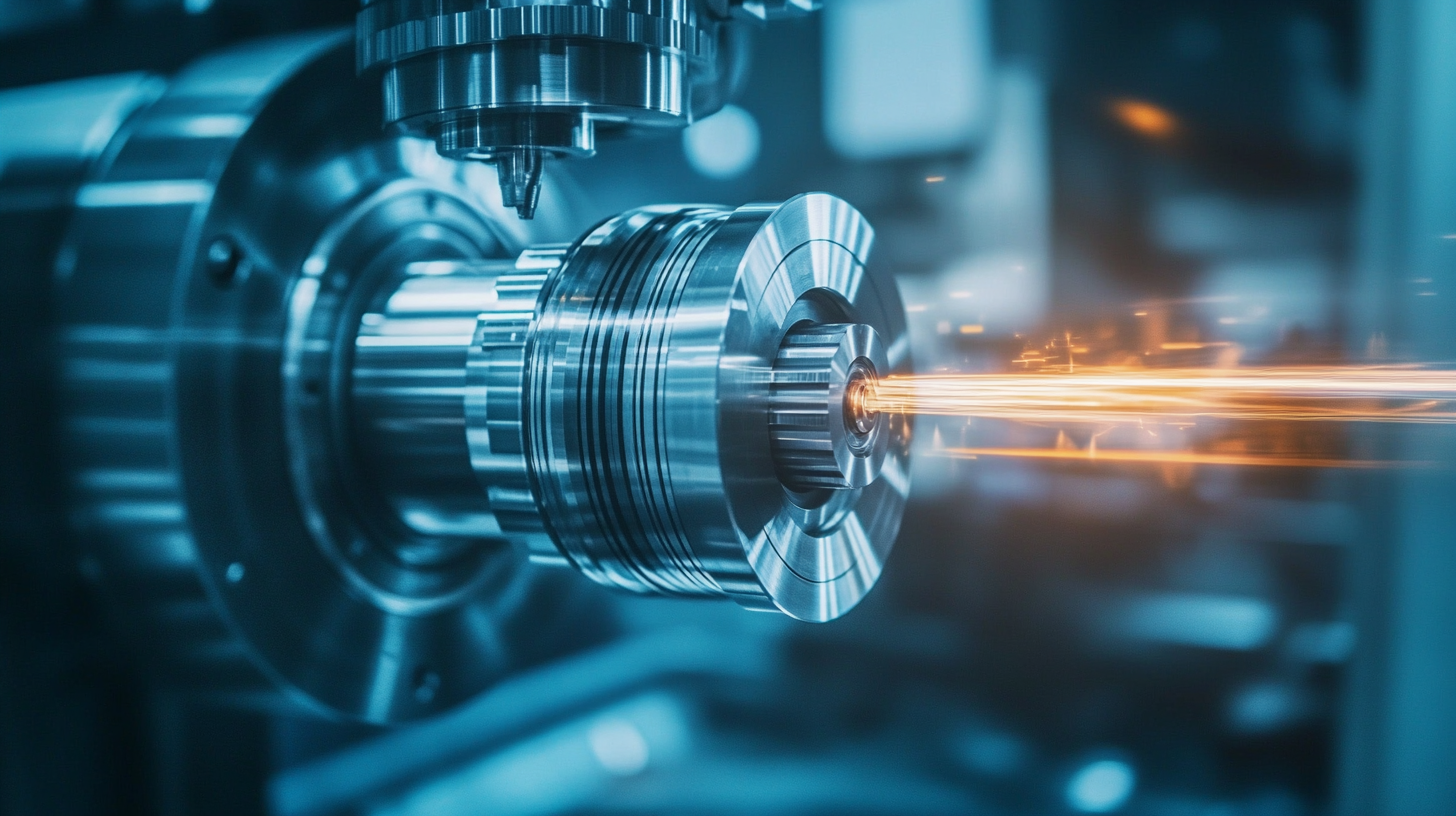

In modern manufacturing, CNC parts play a pivotal role in enhancing efficiency and ensuring precision. As the industry continues to evolve, the integration of advanced technologies such as automation and artificial intelligence into CNC machining processes has become paramount. For instance, automating CNC systems allows manufacturers to significantly increase productivity while maintaining high precision. This transition not only reduces production time but also minimizes human error, leading to more reliable outcomes.

Tip: To maximize efficiency, consider implementing optical inspection systems directly on the shop floor. These technologies enable real-time part assessment, ensuring that any defects are identified and addressed swiftly, which further streamlines the manufacturing process.

As the CNC controller market is projected to grow substantially, manufacturers are encouraged to invest in high-quality CNC parts that can withstand the demands of modern production. Partnering with leaders in the field to adopt innovative solutions can drive substantial improvements in both quality and reliability.

Tip: Invest in cutting-edge CNC lathe and turning technologies, which are designed to enhance wear resistance and precision. Staying ahead with the latest advancements can significantly impact your production capabilities and competitiveness in the market.

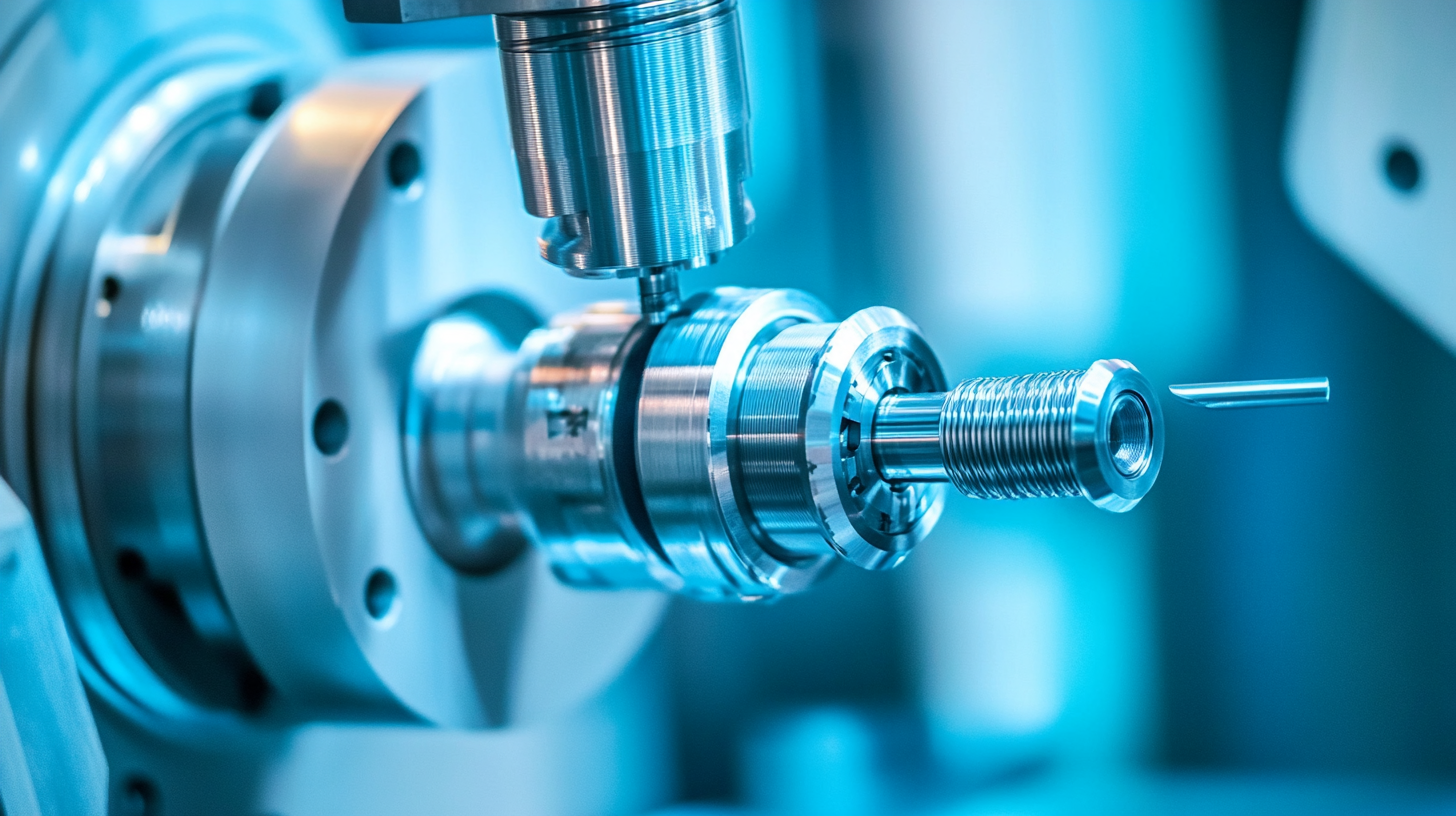

In the realm of modern manufacturing, CNC parts play a crucial role in achieving precision and efficiency. When selecting quality CNC parts, there are several key features that should be prioritized. First and foremost, material quality is essential. Opt for CNC parts made from durable materials such as aluminum or steel that can withstand high-stress conditions. These materials not only enhance the longevity of the parts but also ensure consistent performance within the manufacturing process.

Another vital aspect to consider is precision engineering. High-quality CNC parts are designed with exact specifications to minimize errors during production. Look for parts that boast tight tolerances and superior surface finishes. This will significantly reduce the need for additional machining and ensure a smoother workflow.

Tips for choosing CNC parts effectively include researching the manufacturer’s reputation and previous work. A reputable supplier often provides detailed documentation and instance where their parts have performed successfully. Additionally, consider the availability of after-sales support and warranty options. Having reliable support can offer peace of mind and aid in addressing any issues that may arise post-purchase.

| Feature | Description | Importance |

|---|---|---|

| Material Quality | High-quality materials ensure durability and performance. | Critical for achieving long life and performance reliability. |

| Precision | Tight tolerances allow for accurate machining. | Essential for ensuring parts fit together correctly. |

| Surface Finish | Smooth surface reduces friction and wear. | Important for minimizing maintenance and operational costs. |

| Compatibility | Parts should be compatible with existing equipment. | Crucial for seamless integration and function. |

| Certification | Certification may indicate adherence to quality standards. | Provides assurance of quality and reliability. |

In modern manufacturing, CNC (Computer Numerical Control) parts play a pivotal role in enhancing precision and efficiency. The choice of materials used in CNC machining directly impacts the performance, durability, and cost-effectiveness of the final product. Among the most common materials utilized are aluminum, steel, and plastics, each offering distinct benefits that cater to various industrial needs.

In modern manufacturing, CNC (Computer Numerical Control) parts play a pivotal role in enhancing precision and efficiency. The choice of materials used in CNC machining directly impacts the performance, durability, and cost-effectiveness of the final product. Among the most common materials utilized are aluminum, steel, and plastics, each offering distinct benefits that cater to various industrial needs.

Aluminum is widely favored for its lightweight nature and excellent machinability, making it ideal for applications in aerospace and automotive industries. According to a report by Research and Markets, the global aluminum market for CNC machining is projected to grow at a CAGR of 5.4% from 2023 to 2028, indicating a strong trend towards using aluminum in precision parts. On the other hand, steel, particularly stainless steel, is prized for its strength and corrosion resistance, making it suitable for heavy-duty applications in manufacturing and engineering. Data from Grand View Research highlights that the stainless steel CNC machining market is expected to reach $2.3 billion by 2027, showcasing its rising adoption.

Plastics, such as Nylon and Polycarbonate, are also critical in CNC machining due to their flexibility and lower production costs, with a projected market growth of 4.5% over the next five years, according to a report by Allied Market Research. This versatility allows manufacturers to create complex designs while maintaining budget constraints, thus broadening the scope of possibilities in modern CNC applications.

Choosing the right CNC parts is crucial for optimizing efficiency and precision in modern manufacturing processes. When selecting CNC components, consider the material and design specifications that align with your project requirements. High-quality materials like aluminum or steel can enhance durability, while precision-engineered parts will ensure consistent performance. It's essential to evaluate the compatibility of parts with your existing machinery to avoid operational disruptions.

Additionally, assess the supplier's reputation and customer support services. Reliable suppliers not only provide quality parts but also offer guidance and assistance during the selection process. Pay attention to customer reviews and case studies, as these can give insights into the supplier's reliability and the performance of their parts in real-world applications. Understanding these factors will empower you to make informed decisions that elevate your manufacturing capabilities.

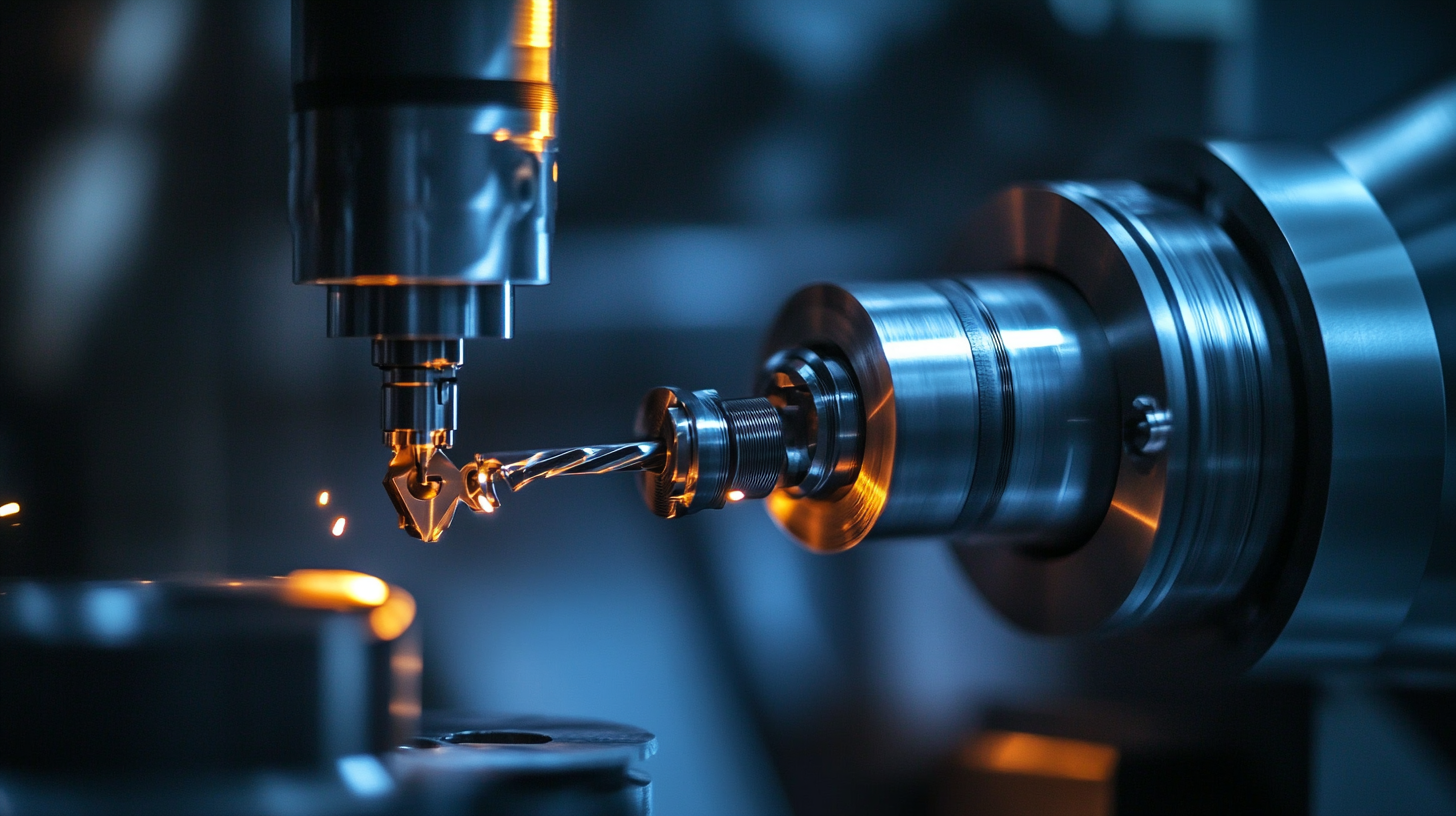

The future of CNC technology is poised for remarkable growth, with the global CNC machine market expected to expand from $101.22 billion in 2025 to an astonishing $195.59 billion by 2032. This impressive growth, driven by a compound annual growth rate of 9.9%, highlights the increasing significance of CNC parts in modern manufacturing processes. As industries seek precision and efficiency, CNC machines are becoming essential for producing high-quality components across various sectors.

The evolution of CNC technology is not just about advancements in machinery; it’s also about the refinement of manufacturing strategies. The integration of 3D printing and CNC operations is creating new possibilities for the production of intricate and customized parts, which can lead to a transformative impact on consumer electronics. As manufacturers invest in innovative technologies and improved precision, the demand for high-quality CNC parts is expected to surge, boosting the industry's growth and positioning it at the forefront of manufacturing excellence.