Investment Casting is a versatile manufacturing process used widely in various industries. By 2026, the demand for this technology is projected to grow significantly, driven by advancements in materials and techniques. According to a report from Future Market Insights, the investment casting market is expected to reach $23 billion by 2027. This figure underscores the importance of exploring how investment casting is evolving.

In 2026, investment casting will be more efficient due to innovations in 3D printing and automation. These advancements allow for complex geometries and reduced production times. Techniques like vacuum investment casting are becoming more prevalent. However, challenges remain, such as the need for high-quality molds and the inherent limitations in material selection.

While investment casting offers precision, it is not without flaws. Companies may face issues with defects such as porosity or surface finish. Continuous improvements in quality control are necessary. As the industry grows, understanding its intricacies will be crucial for manufacturers looking to stay competitive.

Investment casting, also known as lost-wax casting, is a precise manufacturing method used in various industries. In 2026, the investment casting market is projected to reach approximately $22 billion, driven by sectors like aerospace and automotive. The process involves creating a wax pattern, which is then coated with a refractory material. Once the material hardens, the wax is removed, leaving a cavity for molten metal. This creates highly detailed and complex shapes.

Using investment casting, manufacturers can achieve tight tolerances and excellent surface finishes. A report by Allied Market Research states that the aerospace sector accounts for over 40% of the investment casting market share. The ability to produce lightweight components is crucial for aerospace applications. Yet, challenges remain, particularly cost management and material waste. Companies must evaluate their processes regularly to enhance efficiency.

In addition to aerospace, investment casting finds applications in medical devices and industrial machinery. Each sector demands precision and reliability. However, the high setup costs and longer lead times are areas for improvement. Companies need to innovate while balancing quality and cost. Crafting the perfect casting remains a pursuit that drives ongoing research and development in the field.

| Aspect | Description |

|---|---|

| Process | Investment casting, also known as lost-wax casting, is a precision manufacturing process used to create complex metal parts. |

| Materials Used | Commonly used materials include aluminum, steel, brass, and various alloys, allowing for a range of applications. |

| Applications | Widely used in industries like aerospace, automotive, medical devices, and general manufacturing for producing intricate components. |

| Advantages | High accuracy, ability to produce complex shapes, and excellent surface finish are some of the key benefits of investment casting. |

| Disadvantages | Higher initial costs compared to simpler casting methods and longer lead times for mold creation may be considered drawbacks. |

| Future Trends | In 2026, advancements in automation and materials technology are expected to improve efficiency and reduce costs in investment casting. |

| Environmental Impact | Focus on sustainable practices, including recycling materials and reducing emissions, is becoming increasingly important in the industry. |

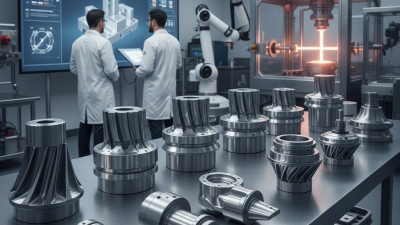

Investment casting is a sophisticated method extensively used in industries requiring precision. The materials chosen for this process significantly impact the final product's quality. Common materials employed include steel alloys, aluminum, and nickel-based alloys, each selected for specific properties.

Steel alloys, for example, are favored for their strength and durability. Reports from industry experts highlight that these materials can achieve tensile strengths exceeding 1,500 MPa. This makes them ideal for heavy machinery components. Aluminum, lightweight and corrosion-resistant, is often utilized in automotive applications. It offers ease of fabrication, though its lower melting point requires careful temperature management during casting.

Another important material is nickel-based alloys. They possess excellent heat resistance, making them suitable for aerospace applications. However, handling these materials can be challenging. They might require complex processing methods, and small errors can lead to defects. This is a crucial point for engineers to consider. Each material's unique properties can create both opportunities and challenges in the investment casting field.

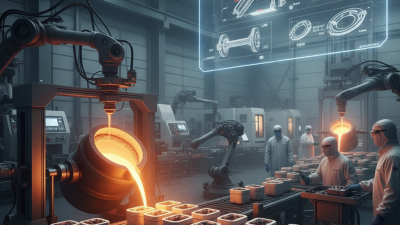

Investment casting is a precision process used to create intricate metal components. This method, also known as lost-wax casting, allows for detailed designs. The process begins with creating a wax pattern. This pattern is a replica of the desired part. The wax is then coated with a ceramic shell, typically made from fine sand. After the shell hardens, the wax is melted away, hence the name lost-wax.

Next, molten metal is poured into the cavity left by the wax pattern. Cooling and solidifying follow this step. Finally, the ceramic shell is removed, revealing the casted part. This method allows for tight tolerances and smooth finishes. However, it requires precision at every stage. Small mistakes can lead to defects in the final product.

Tip 1: Ensure that the wax pattern is flawless. Minor imperfections can translate into significant issues later. Always double-check your mold and tools.

Tip 2: Monitor the cooling rate closely. Uneven cooling can cause warping or cracking. Consistency is key to achieving quality output.

Investing time in refining each step is vital. Reflection on previous projects can guide improvements. Embrace the learning curve as part of the investment casting journey.

Investment casting plays a pivotal role across numerous industries in 2026. This method allows for complex shapes and intricate designs that traditional casting techniques cannot achieve. In the aerospace sector, for instance, lightweight components made through investment casting are gaining traction. The global market for investment casting in aerospace is expected to reach over $5 billion by 2026, according to recent industry reports.

In the automotive industry, investment casting provides precision and efficiency. Manufacturers utilize this method for producing engine parts and transmission components. Data shows a growth of 4.5% annually in this sector, highlighting the technique's importance. Moreover, the medical device industry also benefits from investment casting. Customized surgical instruments and implants are produced with remarkable accuracy.

Tips: When considering investment casting, prioritize design simplicity. Complex designs can lead to higher costs. Evaluate the material properties needed for your application. This approach can prevent costly mistakes.

However, challenges persist. The initial costs may be higher than traditional methods. Production timelines can also be lengthy. These factors require careful planning and execution. Companies must assess their needs realistically.

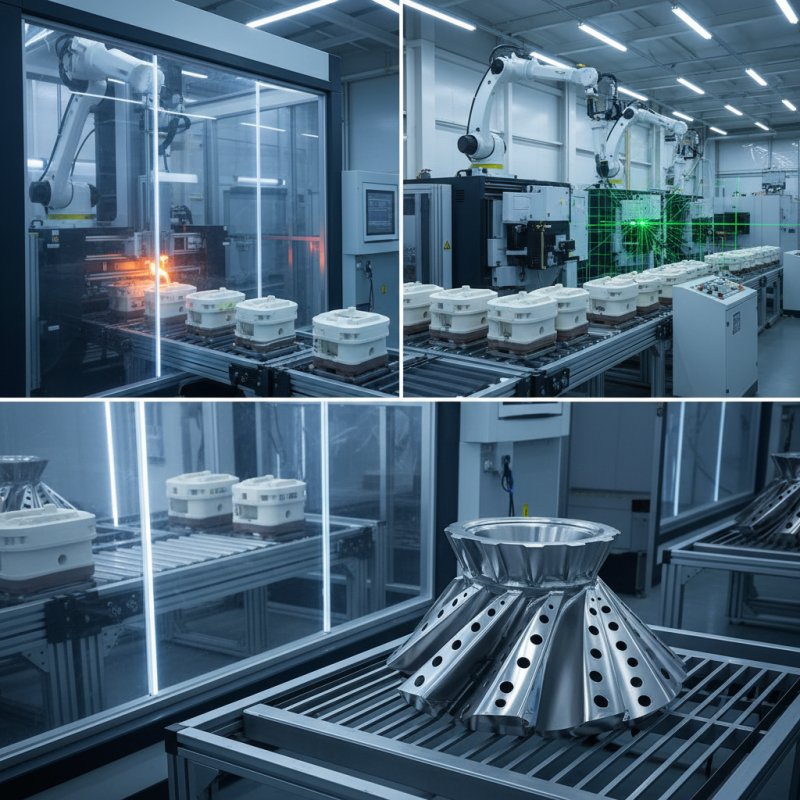

Investment casting technology is evolving rapidly in 2026. This approach has always been about precision and detail. New techniques are enhancing design capabilities. More intricate shapes are possible, which saves time and resources.

Sustainability is becoming crucial. Many manufacturers are adopting eco-friendly materials in their processes. For example, using recycled wax patterns can reduce waste significantly. Such innovations, however, require careful management to ensure quality. Balancing sustainability with high standards is a challenge many face.

Digital advancements also play a role. 3D printing is being integrated into investment casting. This integration allows for complex designs that were once impossible. Yet, the transition isn't seamless. Companies must train their teams and adapt workflows. Embracing these changes can lead to better efficiency and creativity in the long run.