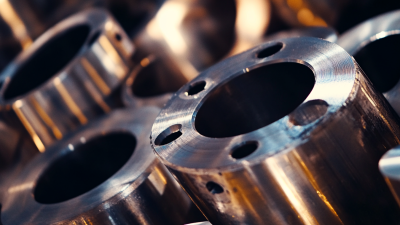

In the rapidly evolving landscape of modern industry, Metal Parts Manufacturing has emerged as a cornerstone for innovation and efficiency. According to a report by MarketsandMarkets, the global metal fabrication market is projected to reach USD 18.7 billion by 2025, growing at a CAGR of 3.5% from 2020. This growth is indicative of the increasing reliance on metal components across diverse sectors such as automotive, aerospace, and electronics. The precision and durability of metal parts enhance product life cycles and performance, making them indispensable in high-tech applications. Furthermore, advancements in manufacturing technology, such as additive manufacturing and CNC machining, are streamlining production processes, reducing waste, and allowing for more complex designs. As industries continue to seek competitive advantages, understanding the key benefits of metal parts manufacturing becomes essential for driving operational success and meeting market demands.

The landscape of metal parts manufacturing has been significantly transformed by innovative technologies that enhance efficiency and precision in production processes. Advanced techniques such as additive manufacturing, also known as 3D printing, allow for the creation of complex geometries that are both lightweight and strong.

This technology not only reduces material waste but also accelerates prototyping and production timelines, enabling manufacturers to respond swiftly to market demands.

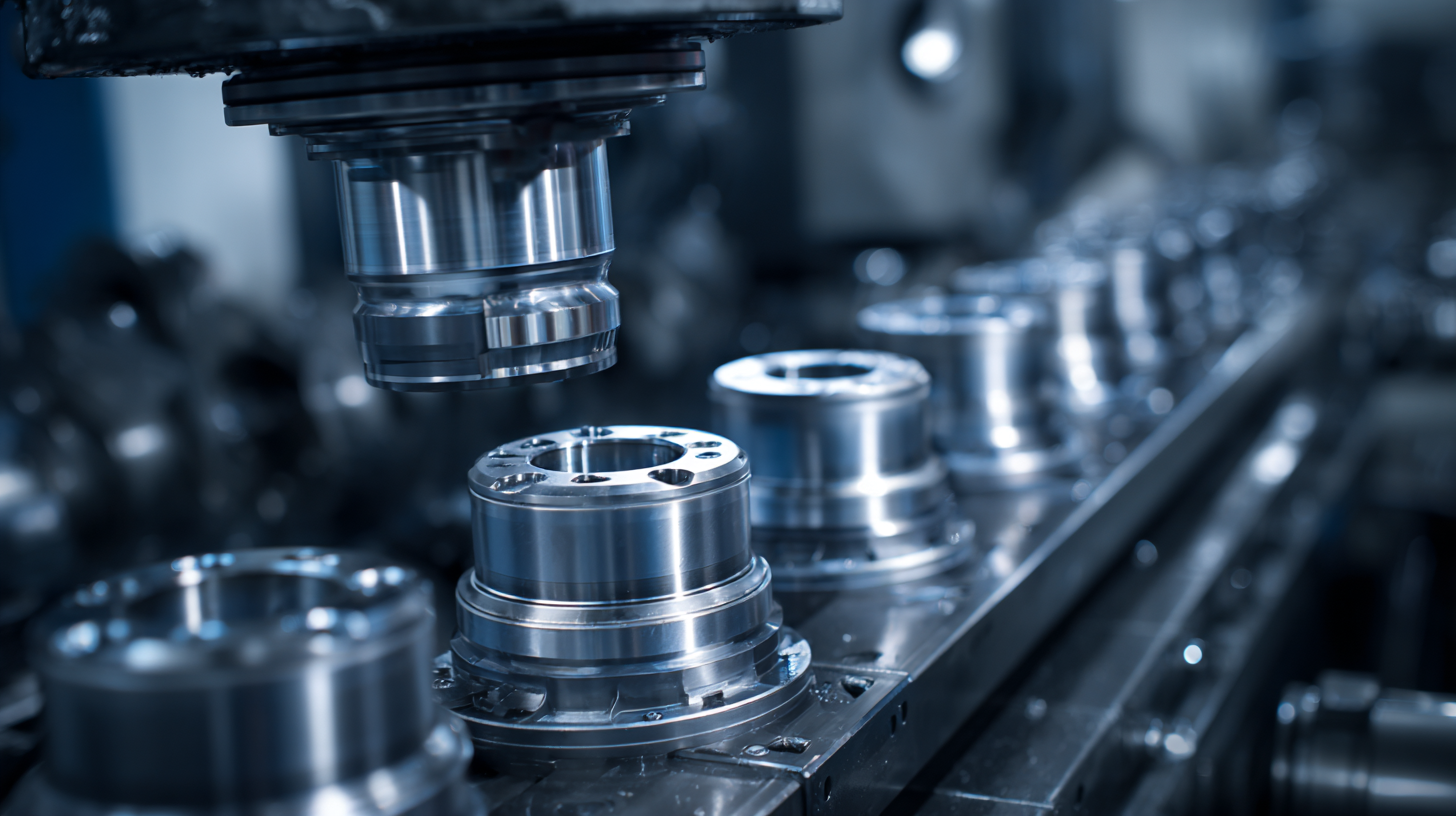

Moreover, the integration of automation and robotics in metal parts manufacturing has further streamlined operations. Automated systems enhance precision in tasks like machining and assembly, minimizing human error and increasing throughput. Additionally, the implementation of smart manufacturing technologies, including the Internet of Things (IoT) and artificial intelligence (AI), allows for real-time monitoring and predictive maintenance of equipment.

This capability ensures uninterrupted production and maximizes operational efficiency, ultimately leading to cost savings and improved product quality in the highly competitive industry.

Sustainability is becoming a focal point in modern metal parts manufacturing, with the industry striving to reduce waste and lower energy consumption. A recent report from the International Energy Agency indicates that metal production alone accounts for approximately 7% of global CO2 emissions. By implementing advanced recycling techniques and using recycled materials, manufacturers can significantly decrease their environmental impact. For instance, using 100% recycled aluminum can result in energy savings of up to 95% compared to extracting new aluminum from ore.

Sustainability is becoming a focal point in modern metal parts manufacturing, with the industry striving to reduce waste and lower energy consumption. A recent report from the International Energy Agency indicates that metal production alone accounts for approximately 7% of global CO2 emissions. By implementing advanced recycling techniques and using recycled materials, manufacturers can significantly decrease their environmental impact. For instance, using 100% recycled aluminum can result in energy savings of up to 95% compared to extracting new aluminum from ore.

To further enhance sustainability efforts, industries can adopt lean manufacturing principles that streamline operations and minimize waste. According to a study by the World Economic Forum, organizations that implement these principles can reduce waste by 30% while simultaneously improving operational efficiency.

Tip: Consider investing in energy-efficient machinery and technology to optimize metal parts production. Not only does this contribute to a lower carbon footprint, but it can also lead to long-term cost savings.

Additionally, fostering a culture of continuous improvement among employees can lead to innovative ideas for reducing excess material usage. Empower your workforce to identify areas where waste can be minimized, as this collective effort can lead to remarkable sustainability gains while enhancing production efficiency.

The shift towards enhanced design flexibility in metal parts manufacturing is significantly driven by advances in technology, particularly in 3D printing. This innovative approach allows for the creation of highly customized components tailored to specific industry needs. As reported, the orthopedic sector has already begun to witness transformative changes through these technologies, enabling practitioners to produce bespoke implants that perfectly fit the unique anatomical requirements of patients. The customization capabilities offered by modern manufacturing techniques not only enhance performance but also reduce waste and lead times, aligning well with the growing demand for personalization across various sectors.

The advantages extend beyond customization to include the integration of Industry 4.0 technologies, which further optimize production processes. For instance, utilizing machine learning and artificial intelligence in conjunction with advanced manufacturing methods can streamline operations and improve supply chain management. Studies show that companies leveraging these technologies can reduce operational costs by as much as 30%, highlighting the financial and efficiency benefits of adopting modern manufacturing solutions. As industries continue to evolve, the ability to produce tailored metal parts on-demand will be a critical factor in maintaining competitive advantage and driving innovation.

This chart represents the scores of key advantages of metal parts manufacturing in modern industries. Each advantage is rated on a scale of 1 to 10, indicating its significance in enhancing flexibility and efficiency in manufacturing processes.

Metal parts manufacturing has emerged as a critical component of modern industry, especially in competitive markets where cost-effectiveness is paramount. Recent market insights indicate that the global powder metallurgy market is expected to be worth USD 6.38 billion by 2034, growing at a CAGR of 8.62% (Custom Market Insights). This growth reflects the increasing demand for efficient and resilient manufacturing processes that can produce quality components at lower costs. Companies are progressively leaning towards powder metallurgy not only for its cost advantages but also for its capacity to create complex geometries that are often unattainable through traditional methods.

Metal parts manufacturing has emerged as a critical component of modern industry, especially in competitive markets where cost-effectiveness is paramount. Recent market insights indicate that the global powder metallurgy market is expected to be worth USD 6.38 billion by 2034, growing at a CAGR of 8.62% (Custom Market Insights). This growth reflects the increasing demand for efficient and resilient manufacturing processes that can produce quality components at lower costs. Companies are progressively leaning towards powder metallurgy not only for its cost advantages but also for its capacity to create complex geometries that are often unattainable through traditional methods.

Additionally, reports highlight that the North American metal fabrication market is projected to grow at a CAGR of 5.75% from 2025 to 2033. The growth is fueled by advancements in technologies that enhance productivity and reduce material wastage. As businesses look to optimize their operations, adopting innovative fabrication techniques becomes essential.

Tips: When considering metal parts manufacturing, evaluate the specific technologies that offer cost savings without compromising quality. Furthermore, staying informed about emerging trends and market forecasts can provide a competitive edge in this rapidly evolving industry.

In today's competitive industrial landscape, metal parts manufacturing stands out for its emphasis on quality control measures. Enhanced quality assurance processes have become integral to metal production, ensuring products not only meet but exceed industry standards. Utilizing advanced technologies such as automated inspection systems and real-time monitoring helps detect anomalies early in the production line. This proactive approach significantly reduces defects and ensures consistency in product quality.

Tips: Implementing a robust quality management system (QMS) can streamline the inspection process and enhance traceability. Consider adopting tools such as Statistical Process Control (SPC) to monitor process variations in real time.

In addition to technology, employee training plays a crucial role in quality control. Skilled professionals who understand quality requirements are indispensable in maintaining high production standards. Regular training sessions and workshops on best practices in metal manufacturing can empower workers to spot potential issues before they escalate, fostering a culture of quality throughout the organization.

Tips: Encourage a continuous improvement mindset among your workforce. Regular feedback loops and incentive programs can motivate employees to take ownership of quality in their respective roles.

| Advantage | Description | Impact on Production | Examples of Implementation |

|---|---|---|---|

| Enhanced Durability | Metal parts are inherently stronger and more resistant to wear and tear. | Reduces replacement costs and maintenance frequency. | High-performance automotive components. |

| Precision Manufacturing | Advanced machining techniques ensure high tolerance and precision. | Improves assembly accuracy and product reliability. | CNC machining in aerospace industry. |

| Cost Efficiency | Bulk production reduces per-unit costs. | Increases profit margins through optimized production. | Mass production of consumer electronics. |

| Sustainability | Recyclability of metals supports eco-friendly practices. | Enhances corporate responsibility and public image. | Use of recycled metals in automotive parts. |

| Technological Advancements | Integration of IoT and automation improves monitoring. | Enables real-time quality assessment and control. | Smart factories employing AI for quality management. |