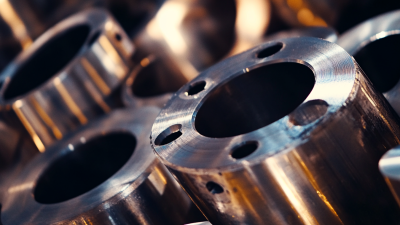

The steel machining industry is witnessing significant growth in 2023, largely driven by technological advancements and increasing demand across various sectors, including automotive, aerospace, and construction. According to a recent report by MarketsandMarkets, the global steel machining market is projected to reach USD 125 billion by the end of this year, growing at a compound annual growth rate (CAGR) of 8.3%. This surge can be attributed to the rising need for precision components and the growing emphasis on lightweight, high-strength materials. Factors such as the implementation of Industry 4.0 technologies, sustainable manufacturing practices, and the expansion of the electric vehicle market are further propelling this trend. As the landscape evolves, understanding the key drivers behind the steel machining industry's expansion becomes essential for stakeholders aiming to leverage emerging opportunities.

The steel machining industry is on the cusp of a significant transformation, propelled by emerging technologies that are redefining traditional manufacturing processes. At the forefront of this revolution is artificial intelligence (AI), which experts identify as a pivotal factor in optimizing manufacturing efficiency and enhancing precision in machining operations. According to recent industry reports, AI-driven technologies can improve supply chain management and procurement processes by up to 20%, signifying a remarkable potential for cost reduction and increased productivity.

In parallel, additive manufacturing continues to revolutionize steel machining. Techniques such as 3D printing are enabling companies to produce complex geometries and structures that were previously impossible with conventional methods. Innovations in AI-powered 3D printing are particularly impressive, as they facilitate quicker production times and enhance the mechanical properties of machined steel products.

Reports indicate that the market for metal 3D printing is projected to grow by more than 30% annually over the next five years, underscoring the critical role these technologies play in the industry's evolution. With the integration of AI and advanced materials, the steel machining industry is set to experience unprecedented growth and efficiency in 2023 and beyond.

In 2023, the steel machining industry is significantly influenced by global demand fluctuations, which are primarily driven by economic conditions and technological advancements. As countries rebound from recent economic challenges, the demand for steel and the components manufactured from it are steadily increasing. This uptick can be attributed to sectors such as automotive and construction, which rely heavily on high-quality steel products. Additionally, increased investment in infrastructure projects around the world is further amplifying the need for innovative machining solutions to meet rigorous quality standards.

Moreover, the market dynamics are also shaped by the shift towards advanced manufacturing technologies. The integration of AI and automation into manufacturing processes is enhancing efficiency and optimizing production. For instance, the growth of the global 5-axis CNC machining centers market underscores the industry’s transition towards more complex and precise machining capabilities. As companies grapple with supply chain challenges and inflationary pressures, embracing these technological advancements becomes critical for maintaining competitiveness. Consequently, players in the steel machining sector must remain agile and responsive to these global demand shifts while investing in future-ready solutions that can withstand market volatility.

The steel machining industry is undergoing substantial transformation in 2023, driven in large part by sustainability initiatives that are reshaping operational practices. According to a recent report from Market Research Future, the global steel industry is projected to reach $1.3 trillion by 2025, with a significant push from eco-friendly processes and materials. As industries strive to reduce their carbon footprints, steel manufacturers are increasingly adopting energy-efficient technologies and sustainable raw materials, aligning themselves with global goals to combat climate change.

Investing in advanced machining techniques is another key to driving sustainability. Companies are leveraging innovations such as additive manufacturing and high-performance steel alloys that require less energy to process. Tips for businesses looking to enhance their sustainability efforts include conducting energy audits, resourcing eco-friendly materials, and staying updated on regulatory changes that affect industry standards. By prioritizing these aspects, manufacturers can not only reduce their environmental impact but also improve operational efficiency.

Furthermore, collaboration plays a pivotal role in fostering sustainable practices in steel machining. Industry stakeholders are encouraged to work together on research and development projects aimed at innovative recycling methods and waste reduction strategies. Joining industry groups focused on sustainability can provide valuable insights and opportunities. Keeping abreast of trends and engaging in community initiatives can significantly enhance a company’s reputation while contributing to a greener future for the steel machining landscape.

| Factor | Description | Impact on Growth |

|---|---|---|

| Sustainability Regulations | Increased government regulations for sustainable practices. | High |

| Technological Advancements | Adoption of automation and smart manufacturing technologies. | Medium |

| Industry 4.0 | Integration of digital technologies into manufacturing processes. | High |

| Global Demand | Rising demand for steel in emerging markets. | High |

| Recycling Initiatives | Focus on recycling steel to reduce environmental impact. | Medium |

| Customization Offers | Expansion of personalized steel solutions for clients. | Medium |

| Skilled Workforce | Investment in training and retaining skilled professionals. | High |

| Material Innovations | Development of advanced materials with enhanced properties. | Medium |

| Economic Rebound | Post-pandemic recovery leading to increased investments. | High |

| Supply Chain Optimization | Focus on improving supply chain efficiency and reliability. | Medium |

As the steel machining industry experiences growth in 2023, one of the critical challenges it faces is the skills gap within the workforce. The rapid advancement of technology, coupled with new manufacturing processes, has created a pressing need for workers who are not only skilled but also adaptable to new tools and techniques. This mismatch between industry demands and workforce capabilities threatens to hinder productivity and innovation.

To address this skills gap, companies must invest in comprehensive training programs that focus on both technical proficiency and soft skills. Collaborative partnerships with educational institutions can help bridge the divide by developing specialized curriculums that cater to the evolving needs of the steel machining industry. Furthermore, fostering a culture of continuous learning and development within organizations will empower employees and enhance their ability to meet the industry's challenges. By prioritizing workforce training, the steel industry can ensure a skilled labor force ready to drive future growth and maintain competitive advantage.

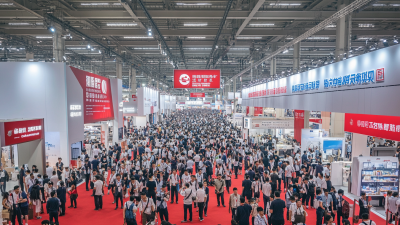

The steel machining industry is experiencing significant growth driven by market dynamics characterized by intense competition and rapid innovation. With projections indicating that the global metal machining market could expand significantly due to rising demands across various sectors, including oil and gas, the race for technological advancement is more crucial than ever. AI's integration into machining processes enhances precision and efficiency, positioning companies that embrace these technologies to gain a competitive advantage.

To stay ahead, manufacturers should focus on adopting the latest machining trends. Implementing self-optimized machine cutting techniques powered by advanced AI can streamline operations and reduce costs. Additionally, investing in 5-axis CNC machining centers is vital, as they offer versatility and improved capability for handling complex designs, which is increasingly demanded in various sectors.

Tips for manufacturers looking to innovate include fostering a culture of continuous learning and adaptation within their teams. Engaging with industry experts to explore cutting-edge technologies and customizing solutions for specific challenges can create unique market advantages. Staying abreast of market trends will not only enhance operational efficiency but will also strengthen the overall positioning of companies in an evolving marketplace.