In the rapidly evolving field of manufacturing, mastering metal fabrication techniques has become crucial for both aspiring and seasoned professionals. According to a report by the Fabricators & Manufacturers Association, the U.S. metal fabrication industry generated over $150 billion in revenue in 2020 alone, illustrating its significant role in the economy. With advancements in technology and increasing demands for precision and efficiency, understanding various metal fabrication processes—such as welding, cutting, and machining—can set you apart in this competitive landscape. Moreover, a survey by the National Association of Manufacturers highlighted that 69% of manufacturers anticipate needing skilled workers proficient in metal fabrication techniques by 2025, underscoring the urgency to enhance your skills in this area. By focusing on practical applications and innovative practices, you can effectively prepare for your next project and contribute significantly to this thriving industry.

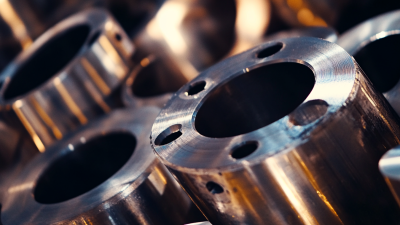

To master metal fabrication techniques effectively, understanding the essential tools and equipment is crucial. According to a report by IBISWorld, the metal fabrication industry has demonstrated a steady growth trend, with market size reaching approximately $114 billion in 2023. This growth underlines the importance of having the right tools to enhance efficiency and precision in various projects. Key tools such as CNC plasma cutters, welding machines, and bending equipment form the backbone of any metal fabrication workshop.

CNC plasma cutters, for instance, are known for their high accuracy and speed, reducing time spent on projects by nearly 30% compared to traditional cutting methods. Additionally, welding machines like MIG and TIG offer various advantages in terms of versatility and quality of the welds, essential for structural integrity. According to a study by Grand View Research, the global welding equipment market is projected to reach $32.4 billion by 2025, signifying the increasing reliance on advanced welding technologies in fabrication processes. By investing in these essential tools, fabricators can elevate their craftsmanship and meet the evolving demands of the industry.

Metal fabrication requires a deep understanding of the various types of metals and their unique properties. Different metals offer distinct characteristics that influence their suitability for specific applications. For instance, aluminum is lightweight and corrosion-resistant, making it ideal for aerospace components, while steel, known for its strength and durability, is preferred in construction. Additionally, specialized metals such as titanium provide exceptional strength-to-weight ratios, highlighting the importance of selecting the right material based on project requirements.

To deepen the understanding of metal properties, recent advancements in research illustrate how molecular dynamics simulations reveal interaction characteristics between molten metals and various materials, which can be crucial for achieving desired outcomes in fabrication processes. Moreover, the electrical properties of metals, as seen in studies on graphene-metal interfaces, emphasize how metal chemistry impacts performance and functionality in electronic applications. This knowledge not only aids in material selection but also enhances the overall efficiency and effectiveness of metal fabrication techniques for diverse sectors.

Mastering welding and joining techniques is essential for effective metal fabrication. To begin, it is crucial to choose the right type of welding method suited for your project. Popular techniques include MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and stick welding. Each method has its advantages: MIG is known for its speed and ease of use, while TIG provides precision suitable for intricate designs. Understanding the materials you're working with, including their melting points and compatibility, will help you select the best method for a durable join.

Once you’ve selected your welding technique, preparation is key. Clean the metal surfaces thoroughly to remove any dirt, rust, or oil, which can weaken the joint. Align the pieces accurately, and use clamps to secure them in place before welding. When you are ready to weld, practice controlling your speed and the angle of the welding torch to ensure a consistent bead. After welding, inspect your joints for any defects and perform post-welding treatments like grinding or sanding for a smooth finish. These step-by-step techniques are vital for achieving strong, reliable welds in your metal fabrication projects.

Metal fabrication can be an exciting venture, but

safety should always be the top priority. When working

with metals and heavy machinery, it's crucial to implement proper safety practices to prevent accidents

and injuries. Ensure that you are wearing appropriate personal protective equipment (PPE), including

gloves, safety glasses, and steel-toed boots. Furthermore, always keep your workspace tidy to minimize

the risk of slips and falls.

Tips: Regularly inspect your tools

and machinery for any signs of wear or damage. A well-maintained tool not only works efficiently but also

prevents unexpected malfunctions that can lead to accidents. Additionally, familiarize yourself with the

safety features of your equipment—knowing how to quickly turn off a machine can make a critical

difference in an emergency.

Another vital precaution is to ensure proper ventilation when cutting or welding metals, as fumes and

dust can pose serious health risks. If you're working indoors, invest in a high-quality exhaust system

or ensure you have access to fresh air.

Tips: Always have a first-aid kit

on hand and know the emergency procedures for your workspace. Brief anyone working with you on the

importance of these practices and ensure they understand the need for vigilance while operating

machinery. Prioritizing safety enables you to focus

on mastering your metal fabrication techniques without unnecessary risk.

When planning and organizing your metal fabrication project, efficiency is key to ensuring a successful outcome. Begin by defining clear objectives and timelines for your project. This approach not only helps streamline processes but also allows for better allocation of resources. For instance, as highlighted in a recent ENERGY STAR guide, many manufacturers are focusing on improving energy efficiency within their processes. In the auto assembly industry alone, over 70 plants produce around 13 million vehicles annually, indicating a massive opportunity for improving operational efficiency through planned processes.

Moreover, leveraging digital technologies is essential. The 2025 Manufacturing Industry Outlook notes that manufacturers are prioritizing investments in their digital and data foundations to boost innovation and address the ongoing skills gap. By employing data-driven strategies, you can not only enhance productivity but also minimize waste in your fabrication project. Implementing tools such as project management software can aid in tracking progress and optimizing workflow, ensuring that every stage of your project is organized and executed effectively.

| Technique | Description | Tools Required | Safety Measures |

|---|---|---|---|

| Welding | Joining two metal pieces together by melting and fusing them. | Welding machine, protective gear, clamps. | Use a helmet, gloves, and work in a ventilated area. |

| Cutting | Removing excess material from metal pieces using power or hand tools. | Cutting saw, plasma cutter, safety goggles. | Wear protective eyewear and hearing protection. |

| Bending | Deforming metal to achieve desired angles and shapes. | Bending machine, templates. | Ensure hands are clear of the bending area. |

| Finishing | Smoothing and cleaning the metal surface to improve appearance. | Grinders, sanders, polishing compounds. | Wear dust mask and gloves to avoid inhalation and cuts. |