The steel investment casting industry is continually evolving. In 2022, the global market was valued at approximately $18 billion. This sector is projected to grow at a CAGR of 5.6% through 2026. Companies are under increasing pressure to enhance efficiency and reduce costs. Optimizing the steel investment casting process is critical for achieving this goal.

One common challenge is achieving the right balance between quality and production speed. A recent study indicates that about 30% of casting defects arise from improper parameters in the investment casting process. These defects can lead to significant financial losses and wasted materials. Therefore, understanding and refining each stage of the process is essential for businesses aiming to improve their outcomes.

Investors must also consider sustainability. Steel investment casting can be resource-intensive, and nearly 70% of companies are seeking greener methods. Implementing advanced technologies can help minimize waste and energy consumption. Companies need to continually assess their practices. Reflecting on current strategies ensures they remain competitive in this dynamic market.

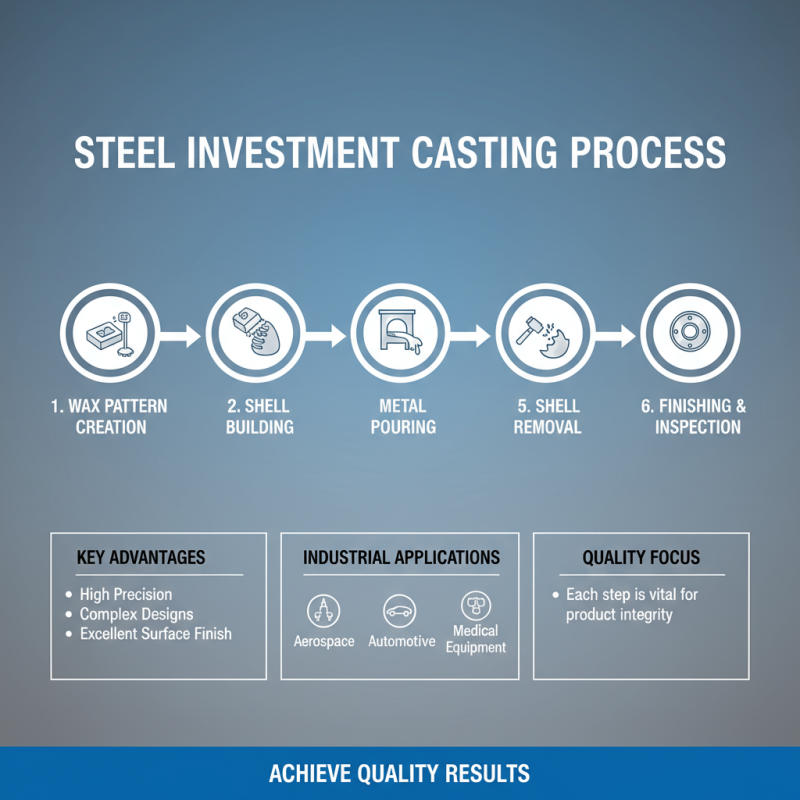

The steel investment casting process is crucial for many industries. This method offers high precision and allows complex designs. It is used in aerospace, automotive, and medical equipment manufacturing. Understanding this process helps in achieving quality results. Each step plays a vital role in the final product’s integrity.

Key aspects include pattern creation and molding. Many overlook the importance of proper mold design. Even minor errors can lead to defects. The melting temperature and pouring technique also require careful attention. Factors like timing and cooling rates influence the outcome. Regularly reviewing these elements can improve results significantly. Some found it challenging to maintain quality standards.

A focus on continuous improvement is vital. Collecting feedback from production runs helps identify flaws. Analyzing these insights can drive process adjustments. Investing time in training staff on best practices ensures consistency. Innovation and adaptation are necessary but often neglected. Emphasizing these areas can optimize the steel investment casting process.

Optimizing the steel investment casting process involves several key factors.

Material selection plays a crucial role.

The choice of steel must align with the desired properties of the final product. Using high-quality alloys can lead to better performance and durability.

However, not all alloys perform well under every condition. Sometimes, lower-cost materials may suffice.

Temperature control is another essential aspect.

Maintaining the right pouring temperature ensures clean fills and reduces the risk of defects.

If the temperature is too low, the casting may not fill properly. If it’s too high, it could lead to oxidation.

Regular monitoring of the temperatures throughout the process can lead to improvements.

Tooling design impacts the efficiency of the casting process.

A well-designed mold can significantly reduce production time. Yet, achieving the perfect design can be challenging.

It often requires adjustments after several test runs. Continuous feedback is vital for optimizing tooling.

Each aspect of the process demands attention and reflection to achieve the best results.

Optimizing material selection in steel investment casting can drastically enhance production efficiency. According to recent industry reports, choosing the right alloy can improve mechanical properties by up to 30%. This emphasizes the importance of rigorous material testing and validation before moving to production.

Different alloys respond differently to casting methods. For instance, stainless steel offers excellent corrosion resistance but may require higher energy inputs during melting. This can lead to increased costs if not managed properly.

On the other hand, carbon steel may provide sufficient strength at a lower cost but may not withstand harsh environments. Finding the balance is crucial.

Moreover, the environment in which the casting will operate must guide material selection. Using incorrect materials can lead to product failures. Some products, like those exposed to high temperatures, demand metals with specific thermal stability. The lack of attention to these details can result in costly reworks or, worse, product recalls. Continuous assessment and adjustment of material choices are necessary for long-term success in the steel investment casting industry.

In the steel investment casting sector, mold design plays a critical role in ensuring quality. A well-designed mold can boost production efficiency by up to 30%. However, many manufacturers overlook this aspect. A recent industry report highlighted that approximately 40% of cast defects arise from poor mold design or inadequate materials. This indicates a pressing need for investment in mold quality.

Incorporating advanced simulation tools can significantly enhance mold design. These tools allow for precise adjustments based on thermal and mechanical stresses, which ultimately lead to better quality parts. Reports indicate that using simulations can reduce scrap rates by as much as 20%. Yet, some companies remain hesitant to adopt new technologies, fearing increased costs. They need to reflect on whether the short-term savings are worth the long-term risks of inefficiency.

Furthermore, selecting the right coating can optimize mold performance. The wrong choice can lead to issues like poor surface finish or faster wear rates. Studies have shown that optimized coatings extend mold longevity by 25%. Yet, many firms still fail to invest adequately in this area. Continuous improvement hinges on recognizing these gaps and addressing them through careful planning and investment.

Implementing process control measures is vital for optimizing your steel investment casting process. According to industry reports, up to 30% of defects in casting can be traced back to insufficient control measures. This includes issues such as temperature fluctuations and inconsistent mold quality. Maintaining a stable temperature is crucial. A variation of just a few degrees can lead to significant discrepancies in the final product.

Moreover, quality assurance often comes down to the data collected during production. Regular monitoring can help identify trends that indicate potential failures. For instance, data analysis reveals that over 40% of reworks stem from undetected irregularities during initial casting. By ensuring strict adherence to process protocols, the likelihood of costly errors decreases substantially. Investing in training for your team is equally important. Skilled personnel can often spot issues that machines might miss. Reflecting on missed opportunities in a process can lead to better outcomes. Making adjustments based on real-time feedback helps evolve your operations.

In conclusion, the significance of systematic process control cannot be overstated. While challenges exist, addressing them head-on can dramatically improve casting quality and overall efficiency. Neglecting this aspect can mean the difference between average and superior casting outcomes.

| Process Control Measure | Impact on Quality | Efficiency Improvement (%) | Cost Reduction (%) | Time Savings (hours) |

|---|---|---|---|---|

| Machine Calibration | High | 15 | 10 | 2 |

| Temperature Control | Very High | 20 | 12 | 3 |

| Quality Inspection | High | 10 | 8 | 1 |

| Material Selection | Very High | 25 | 15 | 4 |

| Process Automation | High | 30 | 20 | 5 |