In today's rapidly evolving global market, optimizing supply chains has become a critical component for enhancing efficiency and cost-effectiveness. According to a report by Deloitte, nearly 79% of organizations with high-performing supply chains achieve revenue growth significantly higher than the average of their industries. One effective strategy for achieving this optimization is through the integration of Alloy Steel Casting Parts, which are renowned for their strength and durability, making them ideal for various applications. A study from MarketsandMarkets indicates that the global investment casting market is projected to reach USD 24.9 billion by 2025, driven by the increasing demand for superior quality materials. By leveraging Alloy Steel Casting Parts, companies can not only enhance their product quality but also achieve sustainable global procurement practices that align with modern supply chain demands.

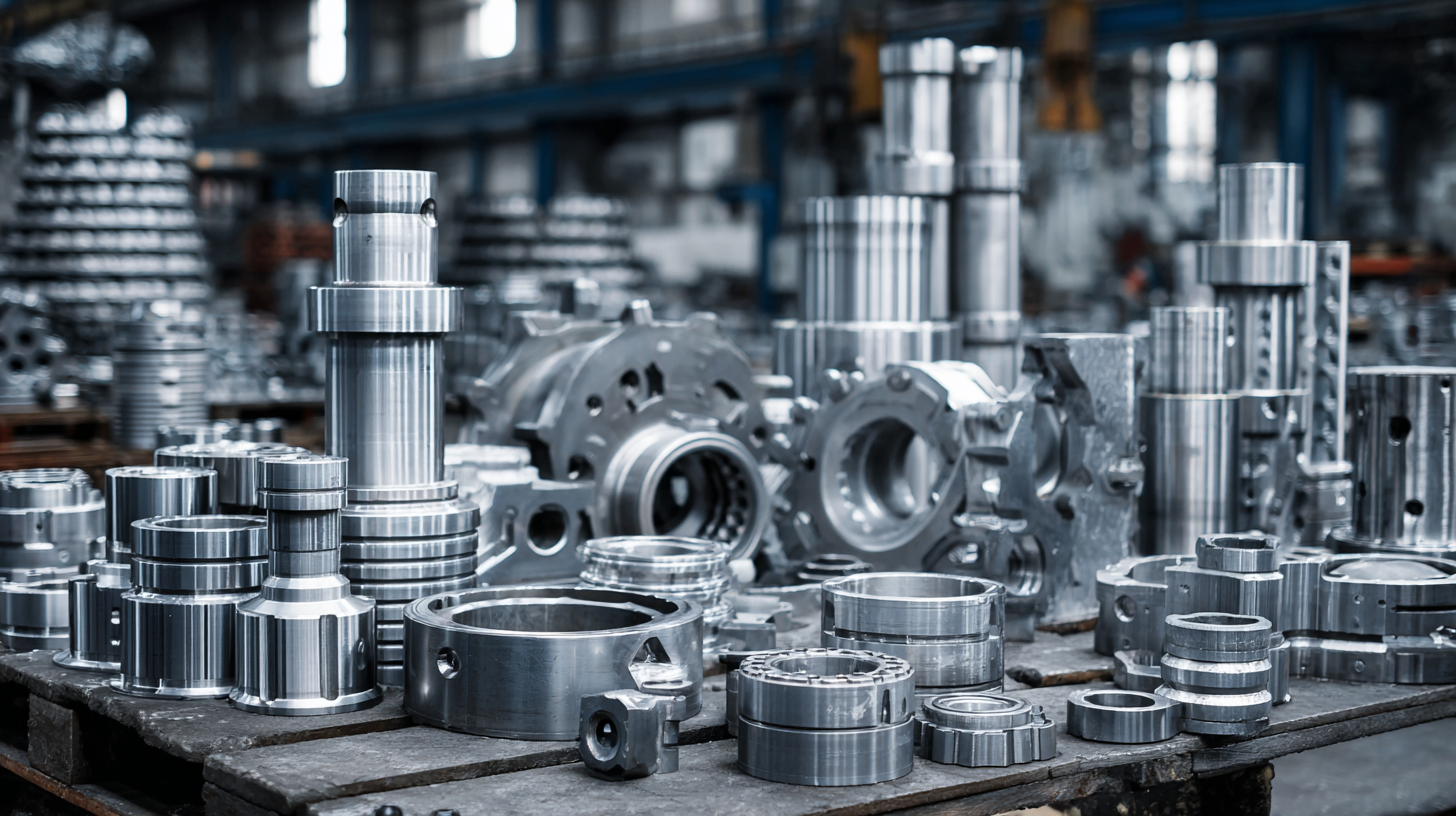

In today's global supply chains, understanding the role of alloy steel casting parts is crucial for optimizing procurement processes. These components, known for their strength and durability, are vital in industries ranging from automotive to aerospace. Their unique properties allow manufacturers to produce high-quality parts that endure harsh conditions, ultimately reducing replacement costs and enhancing product reliability.

Tip #1: When selecting alloy steel casting parts, consider the specific mechanical properties required for your application. Conduct a thorough analysis of the environmental conditions the parts will face, such as temperature fluctuations and exposure to chemicals, to ensure you choose the most suitable alloy.

Additionally, building strong relationships with your suppliers can significantly impact your supply chain efficiency. Consider establishing long-term partnerships with reliable alloy steel casting manufacturers who understand your specific needs and can offer valuable insights on product development and innovations.

Tip #2: Regular communication and feedback with your suppliers can help identify potential issues early, allowing for timely adjustments and fostering a collaborative approach to problem-solving across your supply chain.

Alloy steel casting is becoming a pivotal component in enhancing supply chain efficiency across various industries. The unique properties of alloy steel make it an ideal choice for components that require high strength and durability while maintaining lighter weights. Recent industry reports indicate that the global automotive crankshaft market, which is heavily reliant on such materials, is projected to grow from USD 4,981.1 million in 2024 to USD 7,279.4 million by 2033, reflecting a CAGR of 4.6%. This growth underscores the need for manufacturers to adopt alloy steel casting techniques to meet increasing demands for performance and sustainability.

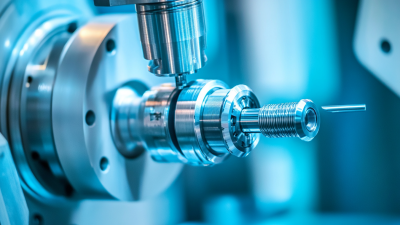

Tips for optimizing your supply chain with alloy steel casting parts include selecting the right casting process. Sand casting, investment casting, and die casting each offer unique advantages. For example, investment casting provides superior surface finish and precision, making it ideal for complex parts. Moreover, leveraging lightweight materials is crucial in meeting stringent emissions targets while enhancing vehicle efficiency. Shift your focus towards integrating high-alloy steel components that ensure both performance and durability, ultimately improving operational efficiency.

To further enhance supply chain performance, consider establishing strategic partnerships with foundries that utilize advanced alloy technologies. Adopting innovative materials opens doors for improved energy efficiency and reduced costs in manufacturing processes. By embracing these practices, companies can achieve a significant competitive edge in their respective markets.

When it comes to global procurement, leveraging alloy steel casting parts can significantly optimize your supply chain while driving cost efficiencies. The use of data analytics is paramount in identifying the most cost-effective suppliers and materials. By analyzing historical data and market trends, businesses can make informed decisions that enhance procurement strategies, minimizing waste and maximizing value.

Moreover, the application of alloy steel in casting provides unparalleled durability and strength, which results in lower maintenance costs over the lifespan of machinery and components. By utilizing predictive analytics, procurement teams can forecast demand more accurately, allowing for reduced inventory holding costs and streamlined operations. This data-driven approach enables companies to negotiate better terms with suppliers by presenting them with solid insights on usage patterns and potential savings, ultimately leading to a more resilient supply chain.

In today's competitive landscape, sourcing alloy steel casting parts effectively is crucial for optimizing supply chains in global markets. One key strategy is to leverage diverse procurement options across different regions. For instance, Turkey has emerged as a significant producer of steel products, offering a robust supply base that can meet varying industry demands. By engaging with local suppliers, businesses can enhance their supply chain's resilience while benefiting from competitive pricing and shorter lead times.

Another vital consideration is staying informed about market trends, such as the recent changes in tariffs that can impact import costs and availability. For example, the increase in aluminum and steel tariffs may necessitate a reevaluation of sourcing strategies, including the shift towards domestic suppliers or alternative materials. Understanding the broader implications of these changes allows companies to make informed decisions that enhance their procurement efficiency and supply chain optimization.

Additionally, adopting modern technologies and processes can further streamline sourcing efforts. The integration of AI and advanced reclamation technologies can facilitate the identification of the best suppliers and ensure sustainable practices in procurement. As the metal injection molding and casting markets evolve, businesses that remain agile and adapt to these dynamics will be better positioned to thrive in a challenging global environment.

When it comes to optimizing your supply chain with alloy steel casting parts, evaluating supplier performance is crucial for successful global procurement. Key metrics for assessing supplier performance can include delivery times, product quality, compliance with specifications, and responsiveness to inquiries. By closely monitoring these factors, companies can identify reliable suppliers that consistently meet their production needs while maintaining high standards.

Another important metric to consider is the total cost of ownership (TCO). This includes not only the initial purchase price but also factors such as freight costs, tariffs, and potential downtime caused by delays or poor quality. Assessing TCO helps businesses make informed decisions when selecting suppliers, ensuring that they are not just choosing based on price but also factoring in long-term sustainability and reliability. Regular supplier evaluations and performance reviews can create a collaborative atmosphere, fostering improvements and aligning the goals of both business and supplier for a more efficient procurement process.