Stainless steel fabrication plays a crucial role in various industries, from construction to automotive, due to its

strength, durability, and resistance to corrosion. According to a report by Grand View Research,

the global stainless steel market is expected to reach USD 200.8 billion by 2025, with a significant portion attributed to advancements

in fabrication techniques. In today's competitive landscape, achieving the best stainless steel fabrication is essential for businesses aiming to enhance

product quality and efficiency. Companies must effectively navigate the complexities of material selection, precision engineering,

and innovative design to meet market demands. Understanding the key secrets behind successful stainless steel fabrication can not only optimize production processes

but also elevate business performance and customer satisfaction. As industries continue to evolve, mastering these fabrication strategies will be

imperative for sustained growth and competitiveness.

Stainless steel fabrication plays a crucial role in various industries, from construction to automotive, due to its

strength, durability, and resistance to corrosion. According to a report by Grand View Research,

the global stainless steel market is expected to reach USD 200.8 billion by 2025, with a significant portion attributed to advancements

in fabrication techniques. In today's competitive landscape, achieving the best stainless steel fabrication is essential for businesses aiming to enhance

product quality and efficiency. Companies must effectively navigate the complexities of material selection, precision engineering,

and innovative design to meet market demands. Understanding the key secrets behind successful stainless steel fabrication can not only optimize production processes

but also elevate business performance and customer satisfaction. As industries continue to evolve, mastering these fabrication strategies will be

imperative for sustained growth and competitiveness.

In the realm of stainless steel fabrication, after-sales service plays a pivotal role in ensuring

long-term success for businesses. The complexities involved in metalworking often mean that clients require ongoing support even after their products are delivered.

This service not only aids in troubleshooting any issues that may arise but also reinforces the relationship between the fabricator and the client. By prioritizing

after-sales service, businesses can enhance customer satisfaction and loyalty, which ultimately leads to

repeat business and referrals.

In the realm of stainless steel fabrication, after-sales service plays a pivotal role in ensuring

long-term success for businesses. The complexities involved in metalworking often mean that clients require ongoing support even after their products are delivered.

This service not only aids in troubleshooting any issues that may arise but also reinforces the relationship between the fabricator and the client. By prioritizing

after-sales service, businesses can enhance customer satisfaction and loyalty, which ultimately leads to

repeat business and referrals.

Furthermore, effective after-sales support can provide valuable insights into the performance of fabricated products. Regular communication with clients allows

manufacturers to gather feedback that can inform future designs or production methods. This iterative process ensures that the products evolve with market needs.

As technology and customer preferences change, responsive after-sales service can help businesses stay relevant and competitive, thereby reinforcing the importance of

investing in ongoing client relationships.

In the competitive landscape of stainless steel fabrication, cost efficiency is a crucial priority for businesses aiming to enhance their bottom line. A recent report by the Fabricators & Manufacturers Association (FMA) highlights that companies can significantly reduce repair expenses, which often account for up to 20% of overall operational costs, by focusing on preventive maintenance and investing in quality materials. By proactively addressing wear and tear before it escalates, businesses not only save on repair costs but also improve their production efficiency and output quality.

Moreover, utilizing advanced fabrication techniques, such as laser cutting and robotic welding, has proven to reduce unnecessary material waste by up to 30%, according to a study from the American Welding Society. These methods not only enhance precision but also minimize the frequency of errors that lead to costly repairs. Implementing these strategies not only improves the longevity of the equipment but also creates a more sustainable operation, making cost efficiency an attainable goal for businesses in the stainless steel fabrication industry.

This chart illustrates the impact of various strategies on reducing repair expenses in stainless steel fabrication. By maximizing cost efficiency through effective methods, businesses can significantly lower their operational costs.

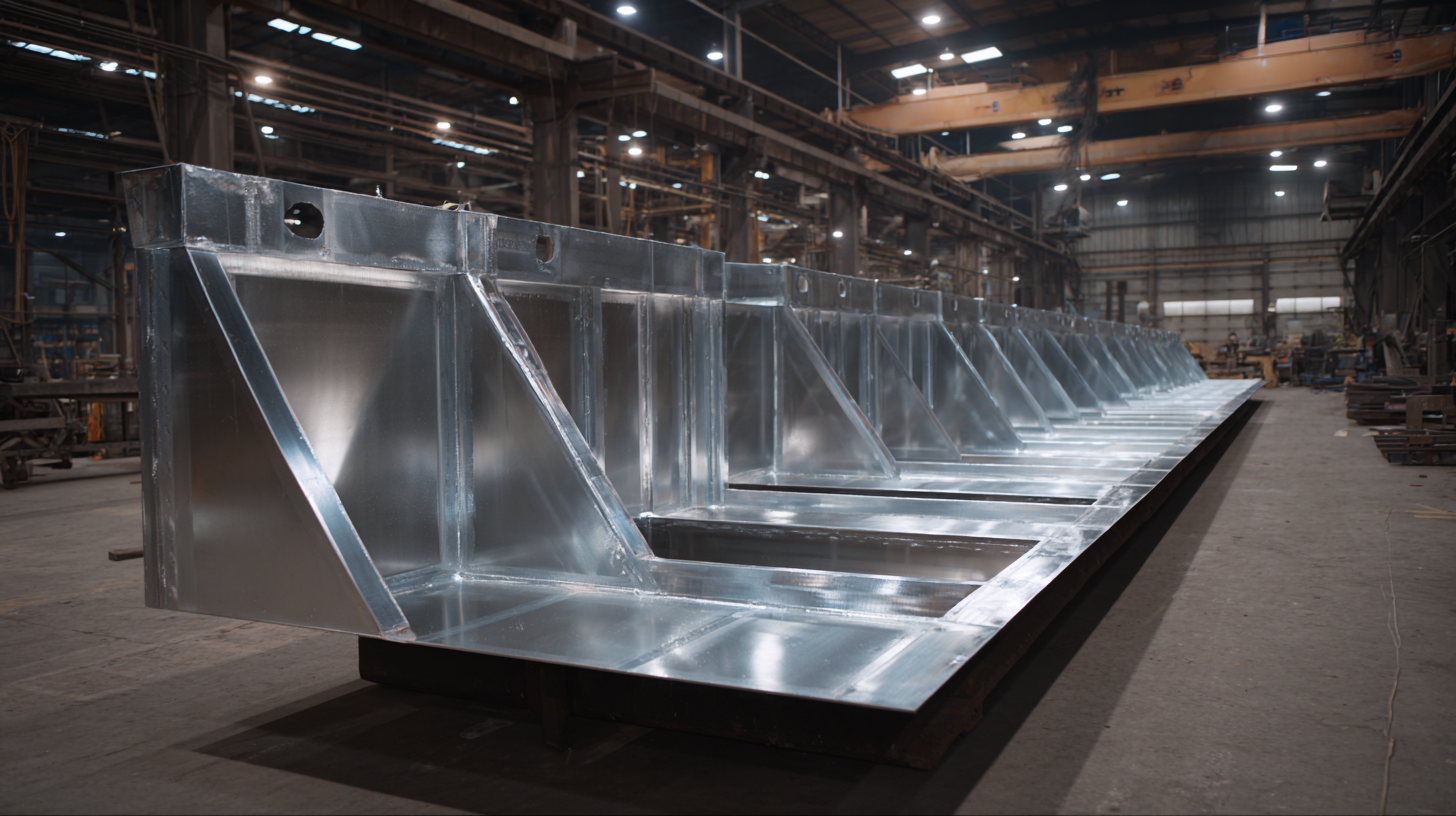

When it comes to stainless steel fabrication, real-world examples often provide the best insights into successful practices. Companies across various industries have implemented unique strategies to overcome challenges and achieve superior results. For instance, a local restaurant chain sought to enhance its kitchen operations by investing in custom stainless steel countertops and shelving. The careful design process reduced clutter, improved workflow, and ultimately led to a notable increase in staff efficiency and food preparation speed.

Another case worth mentioning involves a manufacturing firm that required durable storage solutions for its assembly line. By collaborating with experienced fabricators, they were able to create heavy-duty stainless steel racks tailored to their specific space and requirements. The result was not only increased organization but also improved safety standards, as employees found it easier to access tools and materials. These case studies illustrate that understanding the unique needs of your business and leveraging stainless steel fabrication can lead to remarkable outcomes, reinforcing the importance of collaboration with skilled professionals.

When selecting a fabrication partner for stainless steel projects, it's crucial to consider several key factors that can significantly affect the outcome and longevity of your products. One of the primary considerations is the partner's experience and specialization in stainless steel fabrication. According to a report by IBISWorld, the stainless steel manufacturing industry has seen an annual growth rate of 5.2% over the past five years, indicating a robust demand for skilled fabrication services. An experienced partner can leverage this market knowledge to optimize processes, reduce waste, and ensure high-quality output.

Additionally, evaluating a partner's technology and equipment is essential. Advanced fabrication technologies, such as laser cutting and robotic welding, can enhance precision and efficiency in production. A recent study by MarketsandMarkets forecasts that the global metal fabrication market will reach $18.85 billion by 2027, driven by innovations in manufacturing technologies. Partners who invest in state-of-the-art equipment not only provide better quality products but can also accommodate complex designs and larger production runs, which is essential for meeting your business needs. Consider conducting thorough assessments of potential partners, including site visits and reviews of their past projects, to ensure alignment with your expectations and quality standards.

| Factor | Importance Level | Evaluation Criteria | Example Metrics |

|---|---|---|---|

| Expertise and Experience | High | Years in business, project portfolio | Minimum 10 years experience |

| Quality of Materials | High | Type of stainless steel used | Compliance with ASTM standards |

| Customer Reviews | Medium | Ratings, testimonials | 4 stars and above on major platforms |

| Technology and Equipment | High | Types of machines used | CNC machines, laser cutters available |

| Customer Service | Medium | Response time, support channels | Response within 24 hours |

In recent years, the stainless steel market has seen significant growth, with projections indicating that the Stainless Steel Seamless Pipes Market is set to reach USD 5.15 billion by 2030. This surge highlights the increasing demand for high-quality stainless steel solutions across various industries. Businesses are now focusing on enhancing operations through superior stainless steel products that not only meet industry standards but also improve efficiency and reduce costs.

Furthermore, the Stainless Steel Flexible Hose Market is expected to grow at a CAGR of 4.8%, driven by diverse applications and product types such as corrugated and strip-wound hoses. The adoption of advanced analytics plays a pivotal role in achieving quality improvement while managing expenses, thus transforming how businesses operate. By leveraging insights from market reports, companies can make informed decisions that drive both operational efficiency and product quality, ultimately contributing to enhanced bottom lines. With such advancements, businesses can anticipate improved corrosion resistance and durability in their stainless steel offerings, further solidifying their competitive edge in the market.