In the world of advanced manufacturing, Silica Sol Precision Casting stands out. This technique significantly enhances the quality and accuracy of cast products. According to Dr. Andrew Fisher, a renowned expert in casting technologies, "Silica Sol Precision Casting offers unmatched detail and strength." His insight reflects the industry’s growing reliance on this method.

Silica Sol Precision Casting uses a unique process involving silica sol as the binder. This results in a fine, smooth surface finish. Manufacturers often choose this method for intricate designs. It allows for tight tolerances, which can reduce post-processing efforts. However, achieving the desired precision can be challenging. Variations in temperature and humidity can affect the outcomes. A thorough understanding of the process is crucial.

Despite its advantages, challenges remain. Some may find the initial costs high. Additionally, mastering the technique requires time and training. Exploring these aspects brings clarity to the complexities of Silica Sol Precision Casting. As more industries adopt this method, reflecting on its strengths and weaknesses becomes essential.

Silica sol precision casting is a unique metal casting process. It uses a liquid silica sol to create molds. This technique is known for its high accuracy and smooth finishes. The process is quite precise, which makes it popular in many industries. It particularly shines in producing intricate designs.

Unlike traditional sand casting, silica sol casting offers more detailed and sharper edges. It allows manufacturers to create complex shapes without the need for extensive post-processing. The final products often require less machining, saving time and resources. However, achieving the perfect balance in the mixture is crucial. Too much or too little silica can lead to defects.

**Tips:** Always conduct tests before full production. A small sample can reveal potential issues early. Adjust the silica sol concentration for desired results. Be mindful of temperature changes during casting; they can influence quality. Remember, attention to detail is key. Small mistakes can lead to big problems later on.

| Dimension | Description | Typical Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Type | Silica sol, a colloidal suspension of silica | Aerospace, automotive, medical devices | High precision and surface finish | Higher production costs |

| Process Steps | Pattern making, coating, drying, heat treatment | Luxury jewelry, art castings | Complex shapes and designs | Time-consuming process |

| Temperature Resistance | Can withstand high temperatures | High-temperature components | Durability in harsh environments | Limited to specific alloys |

| Surface Finish | Smooth surface with minimal post-processing needed | Precision machinery parts | Superior aesthetic quality | Challenging to scale production |

| Mold Material | Ceramic molds created from silica sol | High-tech components and intricate designs | Very low dimensional tolerances | Fragile molds can break easily |

Silica sol casting has a rich history dating back to ancient times. Early techniques used sand and clay for casting, but they had limitations. The introduction of silica sol revolutionized the process. It provided improved surface finishes and precision. Artisans began experimenting with this new medium in the mid-20th century.

This method allowed for finer details and complex shapes. It gained popularity in industries like aerospace and automotive. The use of silica sol minimized defects and increased durability. However, the process is not without challenges. Controlling the viscosity and temperature can be tricky. A slight error can lead to flaws in the final product. Manufacturers need to stay focused on refinement and innovation.

As the industry evolves, so do the techniques. New technologies and materials are being integrated into silica sol casting. These advancements aim to enhance efficiency and sustainability. Yet, there is still a long way to go. Balancing quality and cost remains a constant challenge. Continuous learning and adaptation are crucial for success in this field.

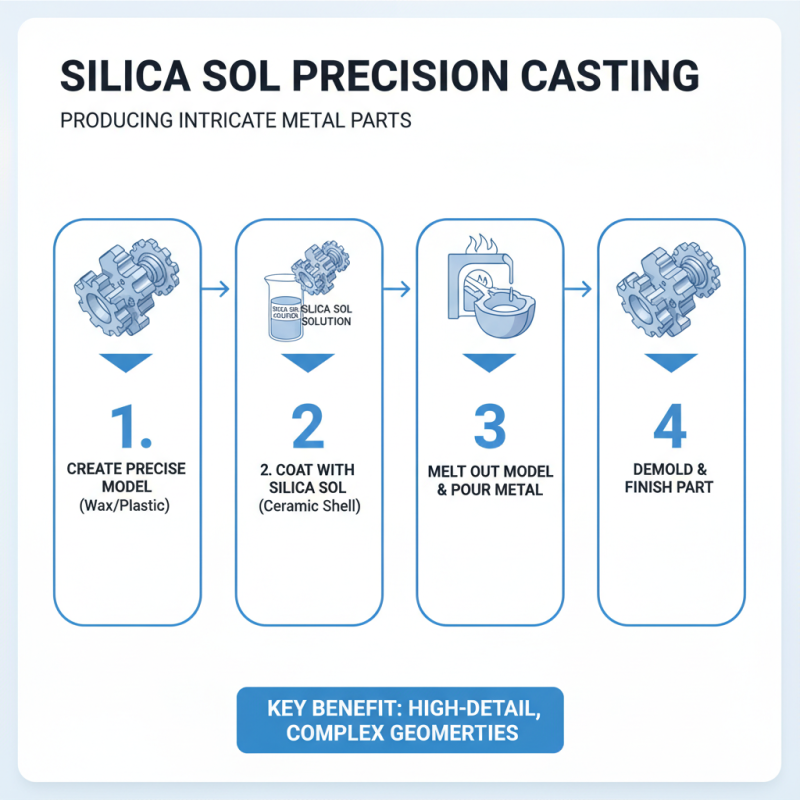

Silica sol precision casting is a unique method of producing intricate metal parts. This process begins with creating a precise model of the desired part. Typically, this model is made from wax or plastic. It’s coated with a silica sol solution. This coating is crucial as it forms the ceramic shell around the model.

Once the model is coated, it is heated to harden the shell. This step can sometimes lead to cracks in the shell. Careful monitoring is needed to avoid this issue. After the shell has set, it is then heated again to melt away the original model. The cavity left behind is where metal will be poured. This part of the process requires close attention; any mistakes can ruin the whole casting.

Finally, molten metal is poured into the cavity. It fills every detail of the shell. Once cooled, the shell is removed, revealing the final piece. The precision of this method allows for tight tolerances, but it’s not without challenges. Achieving the perfect shell thickness can be tricky. Each step demands accuracy and patience. Any slight miscalculation can lead to defects in the final product. Constant reflection and adjustment are necessary throughout the process.

Silica sol precision casting is gaining traction in various industries due to its unique advantages. This technique allows for high-precision components to be produced with intricate designs. It is often used in aerospace, automotive, and medical sectors. The casting process leads to parts that meet tight tolerances and surface finish requirements. This is crucial for applications where reliability and performance are non-negotiable.

In the aerospace industry, silica sol casting helps create lightweight and complex components. These components are essential for improving fuel efficiency and reducing emissions. The automobile sector benefits from this technology as well. Automotive parts produced through silica sol casting exhibit enhanced durability. However, achieving the desired quality can be challenging. The production process requires careful control and monitoring.

**Tip:** Always test different silica sol compositions to find the best fit for your project. Small changes can impact the final product significantly. Monitor the cooling rates closely to ensure optimal results.

Medical devices are another area where silica sol casting shines. Precise and clean designs are mandatory here. Components like surgical instruments require exact specifications. Yet, navigating sterilization processes can complicate casting methods, requiring ongoing refinement in techniques.

**Tip:** Engage with experts during the design phase. They can offer insights that simplify the process and improve outcomes. It’s essential to be open to adjustments.

Silica sol precision casting offers several advantages that appeal to manufacturers. It provides high accuracy, which is crucial for industries needing precise components. The casting process uses a fine ceramic shell, ensuring smooth surfaces. This leads to reduced machining time and costs. Additionally, the method allows for complex shapes, making it ideal for intricate designs.

However, the technology is not without challenges. One significant issue is the cost. The initial setup and material expenses can be high. For smaller manufacturers, this can be a barrier. Furthermore, the casting process requires strict environmental controls. Dust and humidity can affect quality, demanding careful monitoring. This complexity may discourage some potential users.

Moreover, the need for skilled workers presents another challenge. There is a learning curve associated with silica sol precision casting. Training takes time and resources. Without proper expertise, the benefits may not be fully realized. This reality often forces manufacturers to reconsider their options. Embracing new technologies is essential, but it comes with obstacles that require reflection and adaptation.