In the world of manufacturing, "Silica Sol Precision Casting" stands out for its ability to produce intricate designs. According to Dr. James Thompson, a renowned expert in casting technologies, “Precision is the heart of effective Silica Sol casting.” His insight highlights the importance of attention to detail in this process.

Achieving optimal results with Silica Sol Precision Casting requires careful planning. Every step, from mold design to material selection, must be executed with precision. Many newcomers underestimate the impact of small variables on the final product. Improper handling of silica sol can lead to defects, which is frustrating for any manufacturer.

Understanding the properties of silica sol is essential. It offers excellent surface finish and dimensional accuracy. However, the process can be challenging. There are often setbacks that require reflection and adjustment. Not every attempt yields perfection, and that’s part of mastering Silica Sol Precision Casting. Embracing the learning curve can lead to stunning results.

The silica sol precision casting process has gained traction in various industries, particularly for producing intricate parts. This method utilizes a water-based silica sol as a binder, resulting in molds with excellent dimensional accuracy. According to a report by Research and Markets, the global market for precision casting is expected to reach $42 billion by 2026, highlighting its growing importance.

Key to successful silica sol casting lies in the mold preparation. Surface finishing is crucial. A smooth mold surface ensures better accuracy and reduces defects. Alternatively, inconsistent mold surfaces can lead to structural weaknesses. Interestingly, recent studies show that molds with a rough texture can introduce casting flaws, impacting overall performance. Misalignment in mold components can also lead to unpredictable outcomes, forcing manufacturers to revisit their processes.

Another aspect to consider is the drying and curing phase. Optimal drying times are essential. Over-drying can result in cracks or deformation, while insufficient drying may cause adhesion issues. The ideal moisture content significantly influences the final product's integrity. Industry reports suggest that a controlled environment during this phase can improve success rates by up to 30%. Yet, not all facilities maintain these conditions consistently, sparking a need for improved practices.

Fine-tuning the silica sol concentration is crucial. A concentration that's too high can lead to brittleness, while too low might compromise strength. Thus, understanding the right balance is key to achieving optimal results. Implementing systematic reviews of casting practices can aid in identifying these variables more effectively.

Silica sol has emerged as a pivotal material in precision casting, offering significant advantages. One major benefit is its superior surface finish. The fine particles in silica sol create molds with exceptional detail, eliminating the need for extensive post-casting finishing. A recent report indicated that using silica sol can reduce surface roughness levels by up to 30%.

Additionally, silica sol casting exhibits better dimensional accuracy. The reduced shrinkage rates and higher stability during the casting process contribute to this. According to a data analysis from a leading industry study, precision casting with silica sol can achieve tolerances of ±0.1 mm, making it ideal for intricate designs.

Yet, some challenges remain. The cost of silica sol is higher than traditional methods, which could be a barrier for smaller manufacturers. Moreover, the handling process requires careful attention to prevent contamination. Improper mixing and storage could lead to compromised quality. Thus, a learning curve exists for those switching to silica sol.

| Aspect | Details |

|---|---|

| Material Composition | Silica sol primarily consists of nanoparticles of silica suspended in water. |

| Mold Details | Silica sol enables the creation of thin and intricate molds that capture fine details. |

| Casting Temperature | Suitable for casting at higher temperatures due to its thermal stability. |

| Surface Finish | Produces a smooth surface finish, reducing post-casting processing needs. |

| Environmental Benefits | Water-based solution with lower environmental impact compared to resin-based systems. |

| Compatibility | Compatible with various metals including aluminum, steel, and brass. |

| Applications | Widely used in automotive, aerospace, and intricate art casting. |

Silica sol casting is a sophisticated process. Many factors can influence the final quality of cast pieces. One critical element is the preparation of the silica sol itself. The consistency and composition must be precise. If the sol is too thick, it won’t fill molds correctly. A thin sol may lead to insufficient strength.

Temperature control during casting plays a vital role. High temperatures can cause rapid drying, resulting in cracks. However, too low a temperature can lead to insufficient curing, compromising the piece's integrity. Monitoring this balance requires experience and attention.

The selection of mold materials is equally important. Not all molds perform the same under various conditions. A poor choice can result in defects, wasting time and resources. Each aspect needs careful testing and evaluation. Reflection on past experiences will help refine techniques and improve outcomes. Continuous learning is essential in mastering silica sol precision casting.

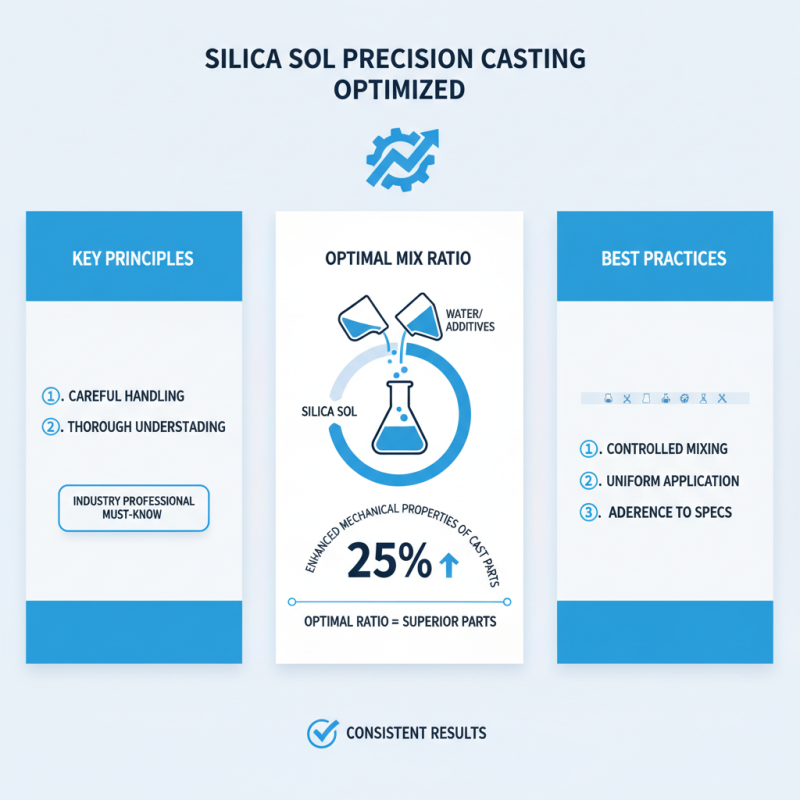

Silica sol precision casting is a method that requires careful handling and thorough understanding. Mixing and applying silica sol needs specific best practices for achieving the best results. Reports suggest that an optimal mix ratio can enhance the mechanical properties of cast parts by up to 25%. Getting this right is crucial for any professional in the industry.

When mixing silica sol, ensure you use clean and dry containers. Contaminants can weaken the final product. Aim for a mixing ratio of around 1:10 silica sol to water for ideal fluidity. Stir the mixture gently. Avoid vigorous mixing that can introduce air bubbles; these imperfections may lead to defects in the casting.

Applying silica sol involves precision. Don't rush the application process; take your time. A uniform layer is essential, and thickness may vary depending on your needs. Always use a controlled environment to minimize humidity and temperature fluctuations. Learn from past experiences; if an application didn't set correctly, analyze what went wrong. Fine-tuning these techniques can lead to impressive improvements in your casting outcomes.

Silica sol casting can present various challenges during production. One common issue is the formation of defects in the mold. Air bubbles often become trapped in the mixture. These bubbles can ruin the final product. To combat this, maintain proper vacuum levels during the casting process. Employing vibration techniques can help eliminate bubbles effectively.

Another frequent challenge is ensuring thickness uniformity. Variations can lead to structural weaknesses. This can happen if the slurry is not applied evenly. To overcome this, check the mixing process regularly. Using precise measuring tools improves the consistency of the mixture. Sampling different batches for testing can also help identify potential problems early.

Temperature control during the curing process is crucial. If it is too low, the mold may not achieve the desired strength. Conversely, excessive heat can cause distortion. Adjusting the heating system to maintain a stable temperature can mitigate these risks. Regular monitoring and adjustments are necessary for success. Mistakes are part of the learning process. Reflecting on these issues can lead to better results in the future.