In the realm of advanced manufacturing, the Steel Casting Foundry process stands out for its pivotal role in shaping a variety of industrial applications. This intricate process involves melting steel, pouring the molten metal into molds, and allowing it to solidify into complex shapes, making it essential for industries ranging from automotive to aerospace. Renowned expert in metallurgy, Dr. John Smith, emphasizes the importance of this process by stating, “Steel casting not only allows for the production of intricate designs but also enhances the durability and performance of components.”

As industries strive for greater efficiency and sustainability, the Steel Casting Foundry process continues to evolve, integrating innovative technologies and methodologies. This adaptability highlights its significance in meeting modern manufacturing demands. With its ability to produce high-quality, customized components at scale, the Steel Casting Foundry serves as a cornerstone for businesses looking to maintain competitiveness in today’s ever-changing market landscape. Thus, understanding the nuances of this process is crucial for both manufacturers and engineers aiming to leverage steel casting in their production strategies.

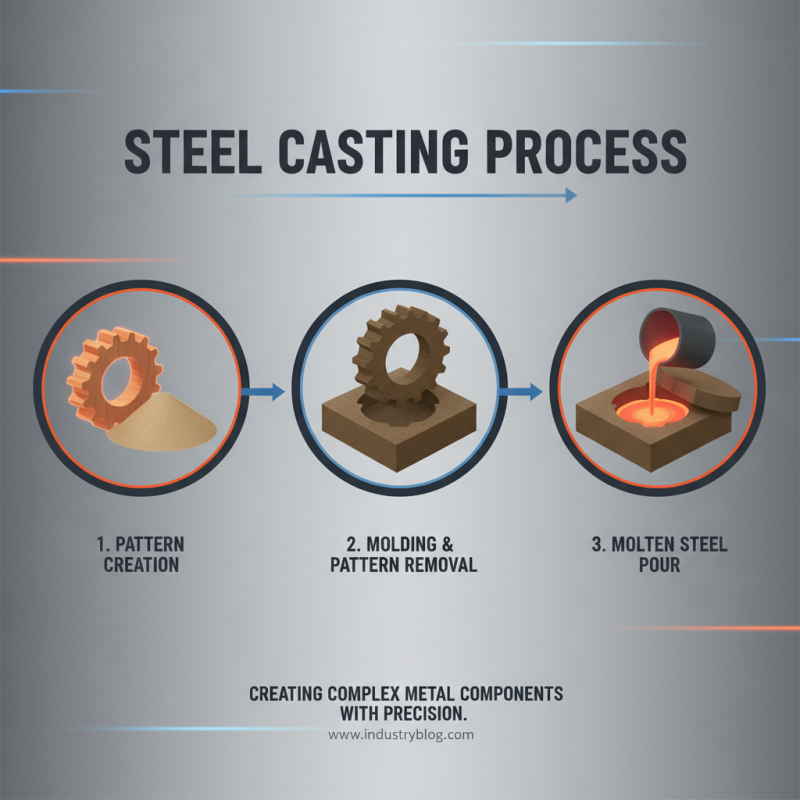

The steel casting process in foundries is a crucial method employed to create complex metal components with precise specifications. This process begins with the creation of a pattern, typically made of wood, plastic, or metal, which shapes the mold. Once the pattern is complete, it is placed in a molding material, such as sand or ceramic, to form a mold cavity. After the mold is set, it is opened to remove the pattern, creating a hollow space that will be filled with molten steel.

Next, the molten steel is produced by melting scrap steel or other iron alloys in a furnace. This molten metal is then poured into the prepared mold cavity under controlled conditions. The cooling process begins immediately, allowing the steel to solidify and take on the desired shape. After the cooling period, the mold is broken away, revealing the cast steel component. This method allows for the production of parts with high dimensional accuracy and quality, making it imperative in the manufacturing sector where precision and performance are essential. The versatility and cost-effectiveness of the steel casting process make it a preferred choice for a wide range of industries, from automotive to aerospace.

The steel casting foundry process is a critical aspect of modern manufacturing, facilitating the production of complex metal components with high precision and durability. Understanding the key steps involved in this process helps ensure quality results and efficient operations.

The primary stages in steel casting begin with pattern making, where a replica of the desired component is created to form the mold. This pattern, often made from materials like wood or foam, is essential for achieving the correct shape. Next, the mold is prepared by creating a cavity in sand or metal, which is then subjected to high temperatures to ensure it can withstand the molten steel. Following this, the pouring process involves transferring the molten steel into the mold, where it cools and solidifies into the final shape. After cooling, the casting is removed from the mold and undergoes finishing processes, such as grinding and machining, to enhance its surface quality and dimensional accuracy.

**Tips:** When working on steel casting, ensure proper ventilation during the pouring process to maintain safety and air quality. Additionally, employing effective temperature control can enhance the quality of the final product by preventing defects like shrinkage. Always conduct thorough inspections of tools and machinery before use to minimize risks and maintain efficiency throughout the casting operation.

The selection of materials in the steel casting foundry process is critical to achieving the desired mechanical properties and functionality of the final product. Steel casting involves the use of various steel alloys, each offering unique characteristics depending on their composition. According to industry reports, high-quality steel castings typically comprise carbon steel, alloy steel, and stainless steel, which are chosen based on factors such as strength, corrosion resistance, and thermal properties.

Carbon steel is often selected for its excellent machinability and weldability, making it ideal for components requiring moderate strength and ductility. Alloys, which may include elements like chromium, nickel, or molybdenum, are utilized to enhance specific characteristics such as toughness or wear resistance; for instance, chromium-molybdenum alloys are commonly used in heavy machinery applications. Stainless steel, known for its resistance to oxidation and corrosion, is favored in industries requiring hygiene, such as food processing or pharmaceuticals. According to a recent market analysis by Smithers Pira, the global demand for steel castings is predicted to increase significantly, underscoring the importance of material selection in improving production efficiency and product longevity.

The selection process often entails rigorous testing and certification protocols to ensure the materials meet industry standards and application requirements. Strategies such as advanced alloying techniques and precise control of furnace atmospheres during casting can lead to significant improvements in mechanical performance. As manufacturing processes evolve, leveraging high-performance materials and innovative casting technologies will be instrumental in addressing the challenges of modern engineering applications while optimizing costs and sustainability.

Quality control measures in steel casting processes are essential for ensuring the integrity and performance of the final products. The complexity of the casting process, which involves pouring molten steel into molds, makes it vital to monitor various parameters throughout production. Quality control typically begins with the selection of raw materials, as the chemical composition and purity directly affect the mechanical properties of the casted steel. Regular testing and analysis of these materials help identify any inconsistencies early in the process.

During the actual casting phase, implementing rigorous monitoring techniques is crucial. This includes maintaining the correct temperature of the molten steel, as overheating or underheating can lead to defects such as porosity or inclusions. Additionally, visual inspections and non-destructive testing methods are employed to identify any surface or internal flaws before the final product is completed.

Tip: Regular training and upskilling of staff involved in quality control can greatly enhance the effectiveness of the measures in place. An informed workforce is better prepared to recognize potential issues as they arise. Furthermore, adopting advanced technologies like automated monitoring systems can facilitate real-time assessments, ultimately leading to higher quality outputs.

Steel casting plays a crucial role in modern manufacturing industries, due to its versatility and strength. According to a report by the Market Research Future, the global steel casting market is expected to reach approximately $150 billion by 2026, growing at a CAGR of around 5.4% from 2019 to 2026. This substantial growth reflects the increasing demand across various sectors, including automotive, aerospace, and oil and gas. Steel castings are favored for their ability to produce intricate shapes and complex geometries while maintaining high tensile strength, making them an ideal choice for critical components like engine blocks and machinery parts.

The importance of steel casting extends beyond just mechanical properties; it also encompasses economic and environmental aspects. Steel casting processes are designed to minimize waste and enhance material usage efficiency. For instance, advanced technologies such as 3D printing in pattern making have been found to reduce lead times significantly, a study by the American Foundry Society indicates a reduction of up to 70% in pattern production time. Moreover, the recycling capabilities of steel—approximately 85% of steel scrap is recycled—further underscore its role in sustainable manufacturing practices. This not only contributes to resource conservation but also helps industries meet stricter environmental regulations while ensuring the durability and longevity of the final products.