Steel Investment Casting has become a preferred method in the manufacturing sector for producing high-quality components with intricate designs and exceptional durability. This advanced casting technique enables manufacturers to create parts that meet stringent specifications while maintaining cost-effectiveness and efficiency in production. The versatility of Steel Investment Casting allows for the production of a diverse range of products across various industries, including automotive, aerospace, and machinery.

One of the key advantages of Steel Investment Casting is its ability to achieve precise dimensions and smooth surface finishes, minimizing the need for extensive machining. This precision not only enhances the performance of the final products but also reduces material waste and labor costs. As the demand for lightweight yet strong materials continues to rise, Steel Investment Casting stands out as a reliable solution that meets these requirements without compromising on quality.

Furthermore, the inherent properties of steel, combined with the meticulous process of investment casting, result in components that exhibit exceptional strength, durability, and resistance to wear. This makes Steel Investment Casting an ideal choice for manufacturers seeking to produce components that can withstand harsh operating conditions while ensuring long-lasting performance. As industries evolve and face new challenges, the adoption of Steel Investment Casting is likely to expand, solidifying its position as a cornerstone in modern manufacturing.

Steel investment casting has emerged as a highly advantageous manufacturing method, particularly for producing complex geometries that require precision and durability. According to a report by Industry Research, the global investment casting market is projected to surpass USD 20 billion by 2025, highlighting the growing demand for this process across various sectors such as automotive, aerospace, and industrial machinery. One of the primary benefits of steel investment casting is its ability to create intricate shapes with excellent dimensional accuracy, which is often unattainable through traditional manufacturing methods. This not only reduces the need for machining but also minimizes waste, making it a more sustainable option for manufacturers.

Another significant advantage of steel investment casting is the material properties it offers. Stainless steel, commonly used in this process, is renowned for its corrosion resistance, high strength-to-weight ratio, and reliability under extreme temperatures. The American Foundry Society notes that components made through investment casting exhibit superior mechanical properties and surface finishes, which can lead to enhanced performance in critical applications. Additionally, the process allows for the integration of features like threads and complex undercuts, which can lower overall assembly costs and streamline production timelines. The combination of precision, material suitability, and cost-effectiveness positions steel investment casting as a preferred choice for modern manufacturing needs.

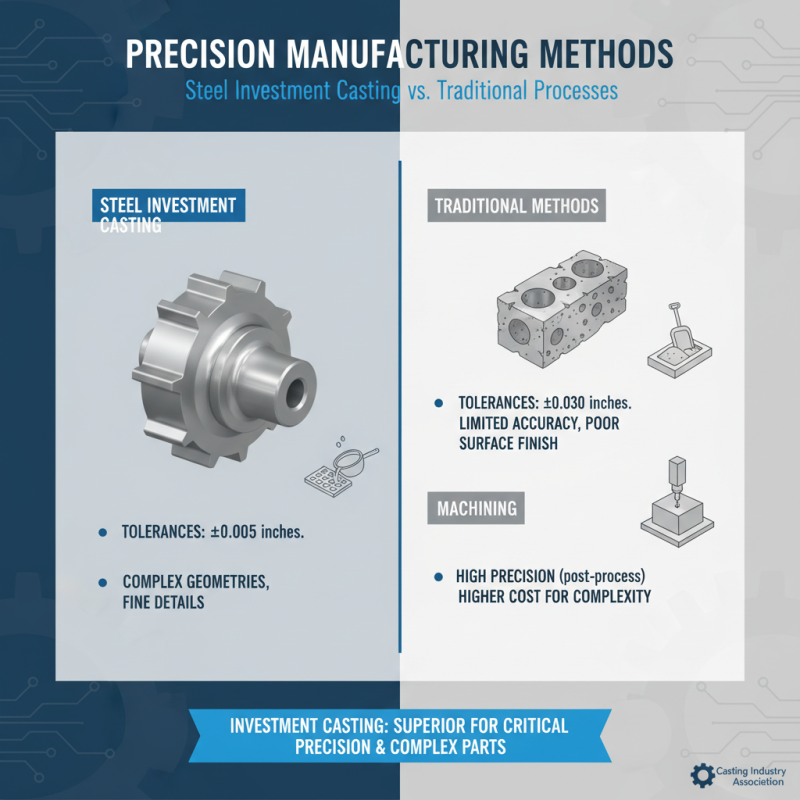

When evaluating manufacturing methods, particularly for precision and complex geometries, steel investment casting stands out against traditional processes like sand casting and machining. According to a report from the Casting Industry Association, investment casting can achieve tolerances as tight as ±0.005 inches, making it ideal for applications where precision is critical. This precision stems from the wax pattern's ability to capture fine details, which is something sand casting, with its inherent limitations in accuracy and surface finish, often struggles to provide.

Additionally, the efficiency of steel investment casting becomes apparent when examining material usage. A study published in the Journal of Materials Processing Technology highlights that investment casting results in less than 1% material wastage compared to over 10% for sand casting. This efficiency not only lowers production costs but also aligns with sustainable manufacturing practices, as reducing waste contributes to a smaller environmental footprint. When compared to machining methods, investment casting can significantly cut lead times for complex parts by bypassing extensive machining processes, proving to be a more time-efficient approach for many manufacturers.

Steel investment casting is a versatile manufacturing process that finds applications in a wide range of industries due to its ability to produce complex shapes with high precision. In the automotive industry, steel investment casting is used to create components such as engine blocks, gearboxes, and suspension parts. The durability and strength of steel allow these components to withstand harsh conditions and heavy loads, making them ideal for vehicles that require high performance and reliability.

In the aerospace sector, steel investment casting is crucial for producing critical components like turbine blades and structural parts. The lightweight nature of steel combined with its high strength-to-weight ratio ensures that aerospace parts meet strict safety and performance standards. Additionally, the medical industry also benefits from this technology, where precisely cast steel components are used in surgical instruments and implants. The ability to customize designs and achieve intricate details makes steel investment casting an attractive option for manufacturers across these diverse fields.

| Industry | Common Applications | Advantages of Steel Investment Casting | Typical Materials Used |

|---|---|---|---|

| Automotive | Engine components, Transmission parts | High strength, Complex geometries | Alloy steels, Stainless steels |

| Aerospace | Aircraft structural components, Turbine blades | Precision, High thermal resistance | High strength steels, Titanium alloys |

| Oil and Gas | Valve bodies, Pump housings | Corrosion resistance, Reliability | Carbon steels, Alloy steel |

| Medical | Surgical instruments, Medical implants | Biocompatibility, Sterilization capability | Stainless steels, Specialty alloys |

| Construction | Reinforcement bars, Structural steel elements | Durability, Cost-effectiveness | Carbon steels, Low alloy steels |

When selecting steel investment casting for manufacturing needs, several key considerations must be taken into account. The first aspect to consider is the complexity of the parts being produced. Steel investment casting excels in creating intricate designs with tight tolerances, making it ideal for components that require detailed features and precision. This capability allows manufacturers to produce parts that are both functional and aesthetically pleasing, reducing the need for extensive secondary machining.

Another critical factor is the choice of materials. Various grades of steel can be used in the investment casting process, each providing distinct mechanical properties suitable for different applications. Understanding the specific requirements for strength, wear resistance, and corrosion resistance is essential. Additionally, environmental factors such as operating temperatures or exposure to chemicals may influence the material selection. Finally, it is important to consider the production volume and cost-effectiveness. While investment casting can be more expensive for low-volume production runs, it offers significant savings in large-scale manufacturing due to reduced material waste and labor costs associated with finishing processes.

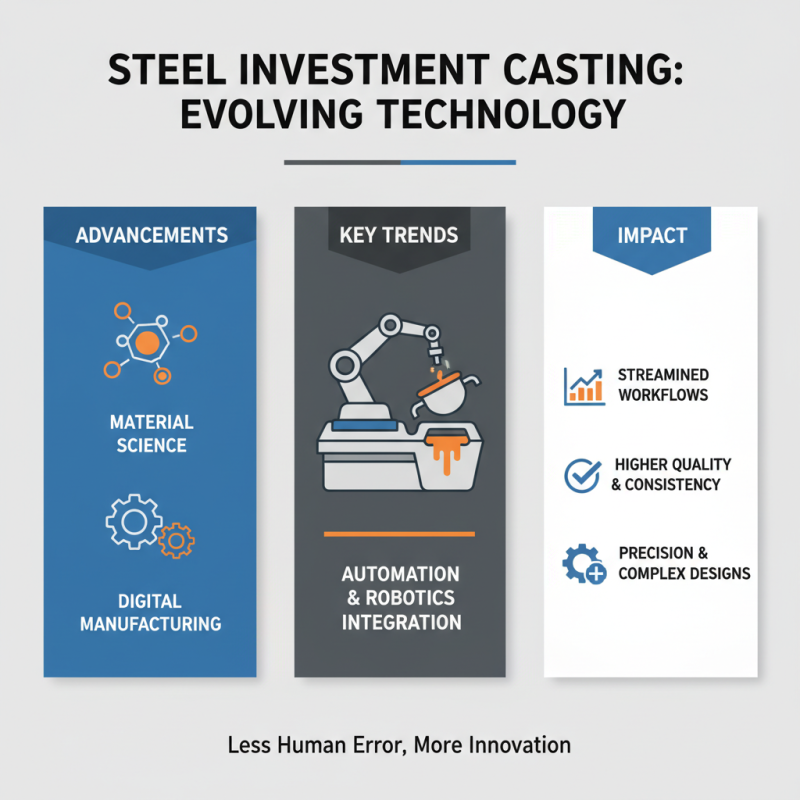

The landscape of steel investment casting technology is evolving rapidly, driven by advancements in material science and digital manufacturing techniques. One of the most significant trends reshaping this sector is the integration of automation and robotics into the casting process. Automated solutions streamline workflows and reduce human error, resulting in higher consistency and quality in cast products. Moreover, robotics enhance the precision of the casting process, allowing manufacturers to produce intricate designs that were previously challenging to achieve.

Another emerging trend is the adoption of additive manufacturing techniques alongside traditional investment casting methods. By utilizing 3D printing to create complex patterns and molds, manufacturers can reduce material waste and shorten production times. This synergy not only opens up new design possibilities but also supports the growing demand for customized steel components tailored to specific applications. Furthermore, advancements in software for simulation and modeling are enabling manufacturers to optimize the casting process, leading to improvements in yield and overall efficiency. As these technologies continue to develop, the future of steel investment casting promises to be more innovative, sustainable, and responsive to market needs.