Steel machining is a critical process in modern manufacturing that significantly impacts various industries, including automotive, aerospace, and construction. According to a report by Grand View Research, the global machining market is expected to reach USD 372.93 billion by 2025, with steel machining representing a substantial share due to its versatility and strength. The ability to produce precise components and tooling from steel allows manufacturers to meet stringent quality standards and reduce production times, which is essential in today’s fast-paced marketplace.

Steel machining is a critical process in modern manufacturing that significantly impacts various industries, including automotive, aerospace, and construction. According to a report by Grand View Research, the global machining market is expected to reach USD 372.93 billion by 2025, with steel machining representing a substantial share due to its versatility and strength. The ability to produce precise components and tooling from steel allows manufacturers to meet stringent quality standards and reduce production times, which is essential in today’s fast-paced marketplace.

The significance of steel machining extends beyond just production efficiency; it also plays a pivotal role in enhancing product performance and durability. In industries where safety and reliability are paramount, such as aerospace, the precision achieved through advanced steel machining techniques is crucial. Furthermore, the increasing trend towards automation and the integration of smart manufacturing technologies are driving innovations in steel machining processes. A report published by Market Research Future indicates that the demand for high-performance machined components will continue to soar, necessitating improved machining capabilities and the adoption of new technologies. Thus, understanding steel machining and its advancements is imperative for stakeholders in the manufacturing sector looking to maintain competitiveness and drive growth.

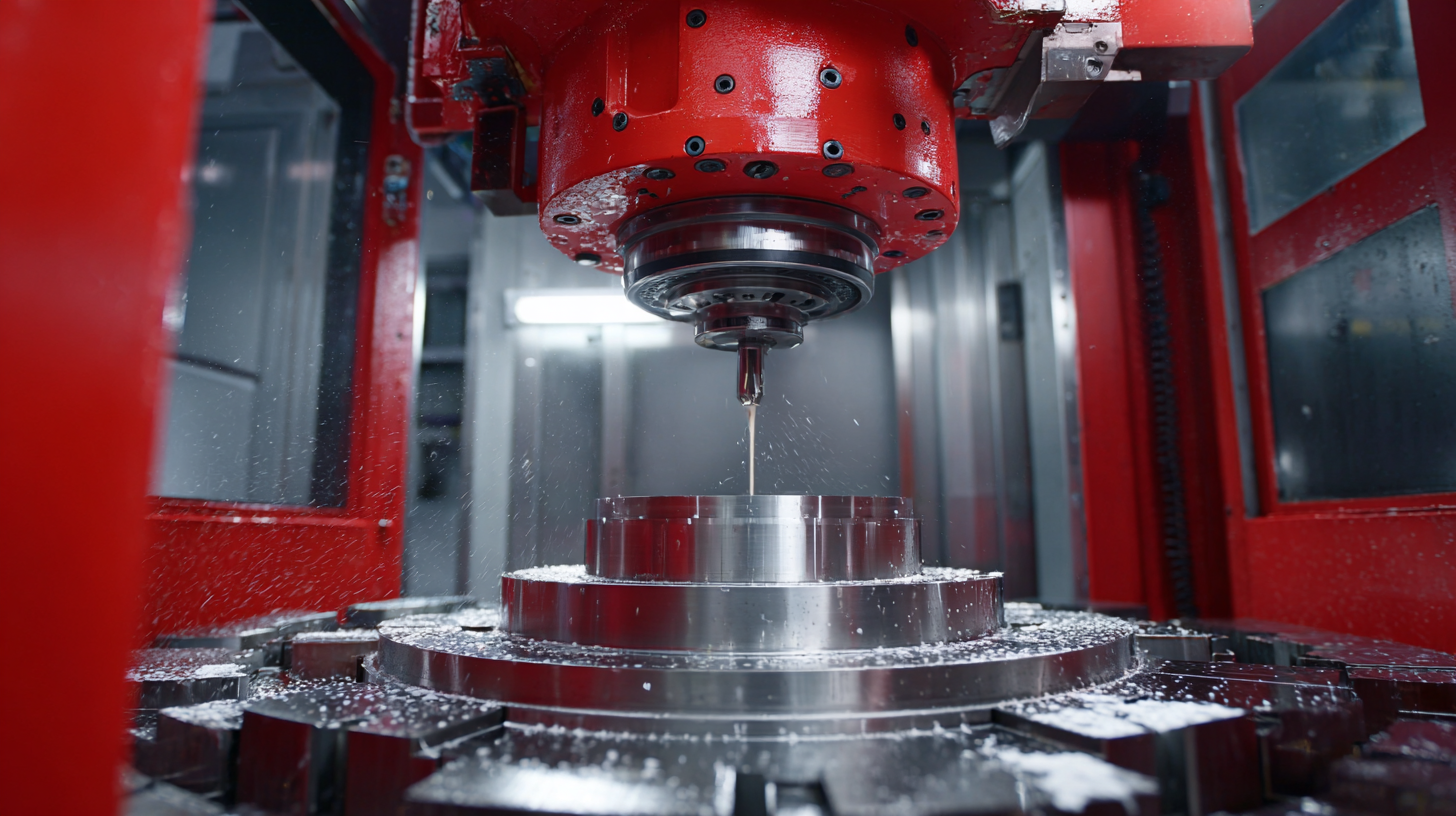

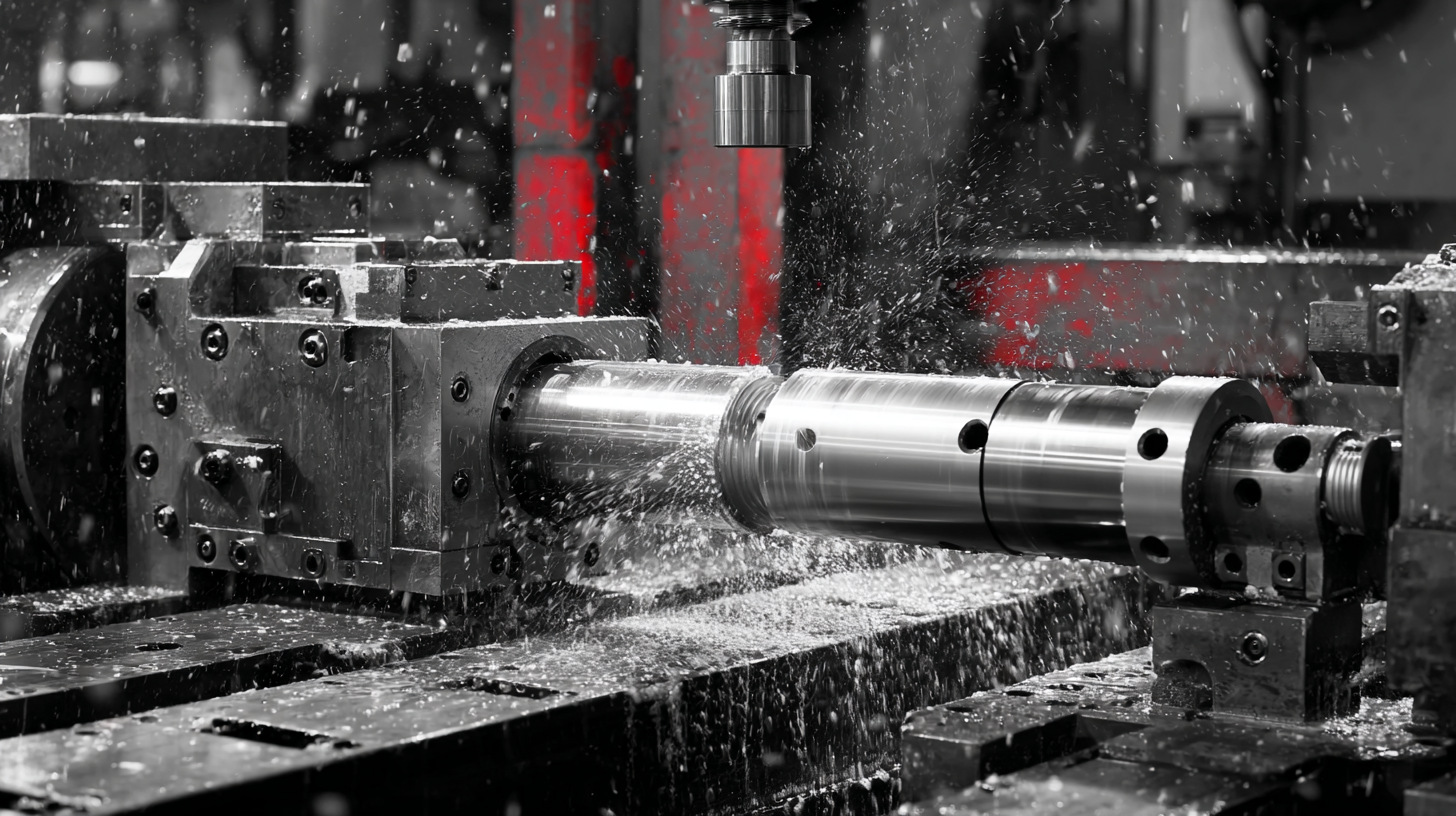

Steel machining plays a crucial role in modern manufacturing by enhancing both efficiency and precision. Recent industry reports highlight that the adoption of digital manufacturing technologies has led to productivity increases of up to 30% across various sectors. For instance, integrating advanced machining technologies such as computer numerical control (CNC) and automation systems enables manufacturers to optimize workflows and reduce downtime, resulting in streamlined operations that meet the demanding requirements of today's market.

Steel machining plays a crucial role in modern manufacturing by enhancing both efficiency and precision. Recent industry reports highlight that the adoption of digital manufacturing technologies has led to productivity increases of up to 30% across various sectors. For instance, integrating advanced machining technologies such as computer numerical control (CNC) and automation systems enables manufacturers to optimize workflows and reduce downtime, resulting in streamlined operations that meet the demanding requirements of today's market.

Furthermore, the accuracy provided by contemporary steel machining techniques is essential for producing high-quality components that adhere to strict specifications. Data suggests that precision machining can improve part tolerances to within 10 microns, which is critical for industries like aerospace and automotive where even the smallest deviations can lead to significant safety concerns. As manufacturers continue to embrace these technologies, the emphasis on durable and precise steel components will only grow, aligning with the industry's goal of achieving excellence in production processes.

Steel machining plays a crucial role in modern manufacturing, and recent trends in the industry reveal significant changes over the past decade. In 2020, the global steel market was heavily influenced by the COVID-19 pandemic, leading to extreme fluctuations in pricing. Early in the year, steel prices fell sharply, but by the third and fourth quarters, prices surged to reach new highs. This volatility highlights the importance of understanding market dynamics and adapting to changing economic conditions.

**Tips:** When engaging in steel machining, it’s essential to stay informed about market trends and pricing strategies to ensure competitiveness. Businesses should also consider diversifying their supply chains to mitigate risks associated with unforeseen market shifts.

Current projections suggest that the steel industry may experience challenges due to overcapacity and insufficient domestic demand. This situation is expected to persist in the upcoming years, affecting production costs and profitability. Steel manufacturers should prioritize efficiency and innovation to navigate these hurdles effectively.

**Tips:** Implementing advanced machining technologies can significantly enhance production efficiency and reduce costs. Additionally, fostering strong supplier relationships can help secure better pricing and ensure reliable access to materials.

In the realm of modern manufacturing, CNC (Computer Numerical Control) machining has emerged as a transformative force in steel fabrication. This technology allows for precise cutting, shaping, and finishing of steel components with incredible accuracy and efficiency. By utilizing computer programming, manufacturers can execute complex designs and repeat them consistently, significantly reducing the margin for error. As the demand for high-quality steel parts grows, CNC machining stands at the forefront, optimizing production processes and enabling customization on a scale previously unattainable.

**Tips for Implementing CNC Machining:**

1. Invest in skilled operators who can effectively manage CNC equipment, ensuring optimal performance and minimal downtime.

2. Regularly update your software and machinery to take advantage of the latest advancements, which can enhance productivity and precision.

3. Emphasize the importance of thorough training on the programming aspect of CNC machining, as this is crucial for unlocking the full potential of this technology.

The rise of CNC machining not only streamlines the fabrication process but also opens new doors for innovation in product design. With its ability to integrate seamlessly with CAD (Computer-Aided Design) software, manufacturers can create intricate designs that were once challenging to produce. This synergy between design and manufacturing heralds a new era where creativity and efficiency coexist, paving the way for advanced steel solutions in various industries.

Steel machining plays a crucial role in enhancing sustainable manufacturing practices by optimizing production processes and reducing waste. The integration of advanced technologies such as CNC machining facilitates precise operations, which not only improves product quality but also minimizes energy consumption. Recent market research indicates a significant growth in the demand for efficient metal machining solutions, highlighting the industry's shift towards sustainability. By implementing strategies that focus on minimizing resource usage, manufacturers can lower their production costs while simultaneously contributing to environmental preservation.

Additionally, sustainable machining practices, such as the use of lightweight materials like magnesium alloys, can lead to further cost savings. A study focusing on the machining of ZE41 magnesium alloy revealed that through optimization techniques like Intuitionistic Fuzzy TOPSIS, manufacturers could significantly decrease energy consumption and production expenses. This approach not only meets the growing demand for sustainable practices but also ensures that cost efficiency is maintained, making it an attractive option for modern manufacturing industries. The ongoing evolution in machining technologies reinforces the importance of sustainability, driving both ecological responsibility and economic viability in manufacturing processes.

The global steel machining sector is poised for significant growth, with projections indicating that the market will expand from $66 billion in 2025 to $103.4 billion by 2032, showcasing a compound annual growth rate (CAGR) of 6.61%. This surge is driven by the increasing demand for high-performance materials across various industries, particularly aviation, defense, and manufacturing. The evolving dynamics of global economies and geopolitical considerations are also influencing steel demand forecasting, particularly as countries like China project their needs through to 2050.

**Tips:** When considering investments in steel machining, keep an eye on emerging trends such as advancements in materials science and automation. These innovations can significantly enhance production efficiency and product quality.

Moreover, the maraging steel market is witnessing a notable uptick, supported by its utility in sectors that prioritize exceptional strength and durability. As the market continues to grow, stakeholders should remain aware of the shifts towards sustainability and eco-friendly production practices that are gaining traction globally. Engaging with these trends not only aligns with regulatory expectations but can also provide a competitive edge in the market.

**Tips:** Regularly assess market reports and forecasts to identify potential opportunities and adjust your strategies accordingly, ensuring you remain ahead in the steel machining landscape.

| Sector | Market Size (2023) | Expected Growth Rate (2023-2028) | Key Trends |

|---|---|---|---|

| Automotive | $45 billion | 5.2% | Integration of AI, Lightweighting |

| Aerospace | $25 billion | 4.5% | Advanced Materials, Additive Manufacturing |

| Construction | $30 billion | 3.8% | Sustainability Practices, Automation |

| Energy | $20 billion | 6.1% | Renewable Energy Integration, Smart Grids |

| Machinery | $10 billion | 4.2% | Robotics, IoT Implementations |