In the realm of precision manufacturing, steel machining stands out as a critical component that underpins the production of high-quality components for various industries. The process involves the intricate shaping and finishing of steel materials to achieve exact specifications required for modern machinery and tools. As manufacturers strive for efficiency and excellence, understanding the best techniques in steel machining becomes paramount. This article delves into the top ten techniques that not only enhance operational performance but also ensure that products meet stringent quality standards.

Precision in machining is essential, as even the slightest deviation can result in significant setbacks in manufacturing. With advancements in technology and innovative approaches, the world of steel machining has evolved, introducing methods that optimize productivity while reducing waste. By exploring these techniques, manufacturers can gain insights that lead to enhanced operational workflows and ultimately, success in their precision manufacturing endeavors. Whether you are an industry veteran or new to the field, embracing these strategies is crucial for staying competitive in an ever-evolving marketplace.

Steel machining techniques are crucial for achieving precision in manufacturing, significantly impacting product quality and operational efficiency. In today's competitive landscape, understanding and applying the right methods are essential for any manufacturer aiming for success. Techniques such as CNC machining, laser cutting, and precision grinding are at the forefront, enabling manufacturers to create intricate designs and maintain tight tolerances that are vital in various industries, from aerospace to automotive.

Tips for manufacturers: Always ensure your machinery is calibrated and maintained regularly to avoid inaccuracies in machining. Additionally, consider investing in high-quality cutting tools as they not only improve the surface finish but also enhance the speed and efficiency of the machining process.

Furthermore, adopting new advancements like automation and smart technologies can streamline operations and reduce manufacturing costs. Implementing real-time monitoring systems allows for immediate feedback on machining processes, leading to faster adjustments and better overall productivity. Emphasizing continuous improvement and training for staff ensures that the workforce remains adept at utilizing these advanced steel machining techniques effectively.

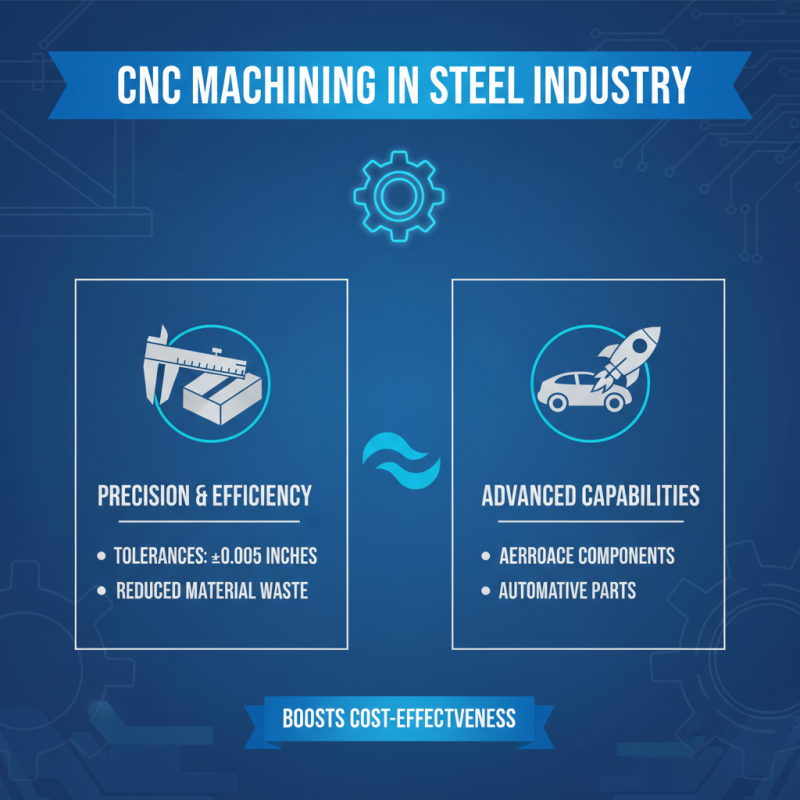

CNC machining has revolutionized the manufacturing landscape, particularly in the steel industry, where precision and efficiency are paramount. Recent industry reports indicate that CNC machines can achieve tolerances as tight as ±0.005 inches, significantly enhancing the capability for exacting specifications critical in aerospace and automotive sectors. These advancements not only meet rigorous quality standards but also contribute to reduced material waste, boosting overall cost-effectiveness.

Moreover, data from the International Federation of Robotics suggests that the adoption of CNC technology in steel machining has increased productivity by up to 30% in some manufacturing environments. The automation and sophistication of CNC systems allow for continuous operation, minimizing downtime and maximizing output. These machines can execute complex machining operations with remarkable speed and repeatability, which is essential for meeting high-volume production demands while maintaining consistent quality. As precision manufacturing continues to evolve, understanding the capabilities and efficiencies of CNC machining is critical for success in the competitive steel manufacturing sector.

In the realm of precision manufacturing, tooling plays a crucial role in the performance and longevity of steel machining techniques. The right tooling not only enhances the efficiency of cutting processes but also significantly influences the quality of the final product. According to a report by the Metal Cutting Institute, proper tool selection can result in up to a 30% increase in machining efficiency and a decrease in material wastage by as much as 20%. This demonstrates the importance of investing in high-quality tooling to achieve optimal operational outcomes.

To maximize machining success, consider these tips: First, ensure that tools are matched to specific steel grades. Different materials may require varying compositions of cutting tools to achieve the desired results. Additionally, regular inspection and maintenance of tools can extend their life by preventing premature wear, leading to more consistent production rates. Finally, utilizing advanced coatings on tools can significantly enhance their durability and performance, with some coatings allowing for higher cutting speeds and improved heat resistance.

To maximize machining success, consider these tips: First, ensure that tools are matched to specific steel grades. Different materials may require varying compositions of cutting tools to achieve the desired results. Additionally, regular inspection and maintenance of tools can extend their life by preventing premature wear, leading to more consistent production rates. Finally, utilizing advanced coatings on tools can significantly enhance their durability and performance, with some coatings allowing for higher cutting speeds and improved heat resistance.

By focusing on tool selection and maintenance, manufacturers can significantly impact their operational longevity and performance in steel machining. Employing these strategies not only promotes higher precision but also drives cost efficiency in the long run, underpinning the success of precision manufacturing initiatives.

In the realm of precision manufacturing, selecting the right machining technique can significantly impact both cost efficiency and quality. The comparative analysis of various steel machining methods reveals that traditional techniques such as turning and milling, while reliable, can be more time-consuming and may incur higher operational costs due to their extensive tool wear and manual intervention.

Conversely, modern methods like CNC machining and laser cutting offer enhanced speed and precision, allowing manufacturers to produce intricate components with minimal waste and reduced cycle times.

Moreover, while evaluating speed and precision, it is crucial to consider the material compatibility with each machining method. For instance, wire electrical discharge machining (EDM) provides exceptional accuracy when working with hard steel, though it often requires a longer lead time and higher upfront costs. In contrast, processes like plasma cutting can handle large-scale operations rapidly but may sacrifice some precision, making them more suitable for less detailed tasks. Ultimately, balancing these factors—cost, speed, and precision—enables manufacturers to tailor their machining strategies to meet specific project requirements and maintain competitiveness in today's fast-paced market.

The future of steel machining is poised for remarkable transformations, driven by innovations that enhance precision and efficiency. One of the most significant trends is the integration of advanced computer numerical control (CNC) technology, which enables manufacturers to achieve higher accuracy with less manual intervention. This technological leap allows for complex geometries and tighter tolerances to be produced consistently, minimizing waste and reducing production time. As industries increasingly demand precision components, CNC machining is becoming indispensable in the steel manufacturing process.

Additionally, the adoption of adaptive machining systems is gaining momentum. These systems utilize real-time data and artificial intelligence to adjust machining parameters dynamically, ensuring optimal performance based on the material condition and machining environment. This not only maximizes efficiency but also extends tool life, leading to lower operational costs. Moreover, the push towards sustainability in manufacturing drives innovation, with processes being developed that require less energy and produce fewer emissions. Together, these advancements signify a promising future for steel machining, where precision manufacturing can meet the evolving demands of various applications across industries.

This bar chart illustrates the popularity ratings of the top 10 steel machining techniques that are driving precision manufacturing innovations. Each technique is evaluated on a scale from 1 to 10 based on its effectiveness and implementation in the industry.