The world of Stainless Steel Fabrication is evolving rapidly. As we approach 2026, industry experts emphasize the importance of innovative techniques. John Smith, a noted expert in stainless steel manufacturing, states, "Adapting to new technologies is vital for success in fabrication." His insight reflects the ongoing transformation within this sector.

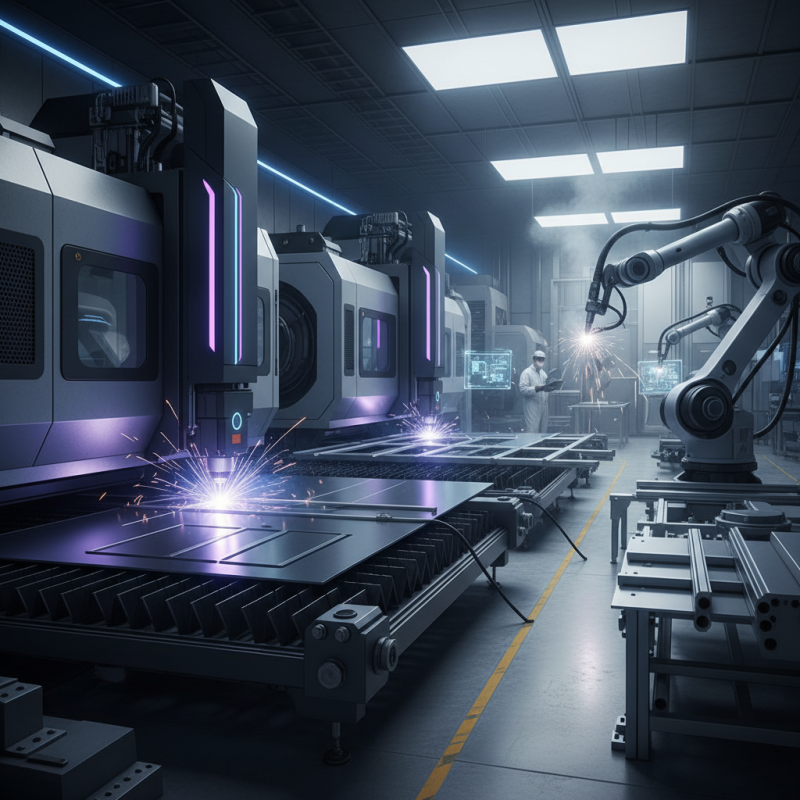

Stainless Steel Fabrication involves various methods, including cutting, welding, and finishing. Each technique has its own challenges and opportunities. For instance, laser cutting is precise but requires significant investment in equipment. Moreover, the balance between efficiency and quality often demands scrutiny.

Innovation brings both excitement and uncertainty. While advanced techniques can enhance production, they may also complicate processes. As the industry progresses, it is essential to evaluate the effectiveness of new methods. The journey of stainless steel fabrication is filled with trial and error, requiring continuous reflection and adaptation.

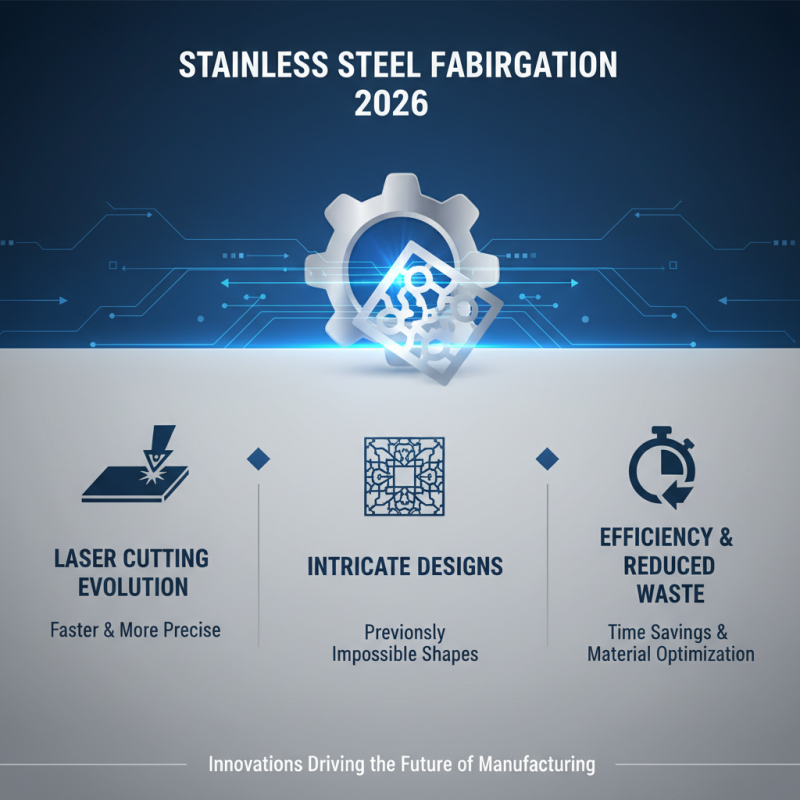

As we look toward 2026, stainless steel fabrication techniques continue to evolve. Innovations in laser cutting are making processes faster and more precise. These advancements enable manufacturers to create intricate designs that were not possible in the past. The ability to cut complex shapes with high accuracy saves time and reduces waste.

Another exciting area of development is robotic welding. Robots are increasingly used for welding stainless steel. They offer consistent quality and speed that human welders can’t match. However, relying on automation poses challenges. Training staff to work alongside machines is vital for success. There may also be a period of adjustment where production slows as teams adapt.

Finally, new surface finishing techniques are emerging, enhancing both aesthetics and durability. Techniques like electropolishing improve the resistance of stainless steel to corrosion. This raises production costs but could lead to a longer product lifespan. Balancing cost with quality remains a challenge for many fabricators in adapting to these advancements. The future is bright, but it is vital to address these complexities.

Welding is crucial in stainless steel fabrication. Different methods can significantly enhance the strength and durability of finished products. TIG welding remains popular due to its precision. It allows for clean welds without adding extra filler metal. The key is to control the heat and maintain a steady hand.

MIG welding, on the other hand, is faster and more efficient for larger projects. It’s a great choice for thicker stainless steel. However, the quality can vary. Proper training is essential. Always assess the equipment before starting.

Tip: Practice on scrap materials to improve your skills. Mistakes happen, and every weld is a learning opportunity. You should try to identify common issues like warping or excessive spatter. Understanding these can help you adjust your techniques early.

Another method gaining attention is laser welding. It offers excellent speed and precision. However, the cost of equipment can be a barrier. Consider if the investment aligns with your production goals. Evaluate your project needs and the potential return on investment.

CNC machining has transformed the fabrication of stainless steel components. This technology allows for precision and efficiency that traditional methods often lack. Parts can be designed with complex geometries, which is essential for modern industries. For instance, intricate brackets or housing units can be produced with minimal waste.

However, there are challenges to consider. Programming errors can lead to costly mistakes. The learning curve for CNC technology can be steep for some operators. Moreover, stainless steel is a tough material. Machining it requires the right tools and understanding of the material's properties. Avoiding overheating is crucial, as this can affect the integrity of the components.

As we look ahead, innovative applications continue to emerge. Automation in CNC machining is becoming more prevalent. This shift promises to enhance productivity but also raises concerns about job displacement. Balancing advancement with a skilled workforce is a conversation to monitor as we move toward 2026. The future presents opportunities and challenges that require careful navigation.

This chart illustrates the projected usage of various stainless steel fabrication techniques in 2026, highlighting the rise of innovative CNC machining applications for stainless steel components.

The stainless steel industry is rapidly evolving. Surface finishing techniques are critical for achieving desired aesthetics and performance. In 2026, the demand for modern finishes is expected to rise by 30%. This shift emphasizes the need for improved corrosion resistance and aesthetic appeal.

One notable trend is the increased use of mechanical finishing and the rise of advanced grinding techniques. Mechanical polishing may enhance the material's look and longevity. However, achieving uniformity remains challenging. Reports indicate inconsistencies can impact product quality. Another innovation is electrochemical polishing. This method can create a smoother surface but requires precise control. Inconsistent application could lead to unexpected results.

Environmental considerations are crucial, too. Emerging techniques aim to reduce waste and energy usage. One report highlights a potential 25% reduction in energy consumption by adopting new surface treatments. Yet, not all companies have adopted these methods. A gap exists between innovation and implementation. Staying competitive demands continuous improvement in both process and product. Understanding these factors is key for manufacturers striving for excellence in 2026.

| Technique | Description | Benefits | Applications | Trends for 2026 |

|---|---|---|---|---|

| Laser Cutting | Uses a laser to cut stainless steel with high precision. | High accuracy, minimal waste, and quick setup. | Automotive, aerospace, and medical devices. | Increased use in custom designs and prototyping. |

| Welding | Joining stainless steel parts using high heat. | Strong joints, versatile processes. | Construction, pipelines, and structures. | Adoption of advanced robotic welding systems. |

| Milling | Machining process that uses rotary cutters to remove material. | High material removal rates and precision. | Tool manufacturing and industrial components. | Integration of CNC technology for automated processes. |

| Surface Finishing | Processes to enhance surface properties. | Improved corrosion resistance and aesthetics. | Consumer goods and architectural applications. | Trend towards eco-friendly and sustainable methods. |

| 3D Printing | Additive manufacturing technique for metal parts. | Reduction in material waste and design flexibility. | Prototype development and customized solutions. | Expanding capabilities in complex geometries. |

Sustainable practices in stainless steel fabrication are vital for a cleaner future. The industry is shifting focus towards reducing carbon footprints and waste. According to a 2023 report by the International Stainless Steel Forum, around 40% of stainless steel production now utilizes recycled materials. This trend not only conserves resources but also lowers energy consumption.

Tip: Consider using suppliers that prioritize eco-friendly processes. This choice can significantly enhance your sustainability profile.

Adopting advanced technologies is another essential step. Techniques such as waterjet cutting and laser fabrication minimize waste and maximize efficiency. Reports indicate that these innovations can reduce operational waste by up to 30%. While technologies advance, challenges remain in their implementation.

Tip: Regular training for staff on new sustainable technologies is crucial. Keeping the team updated helps in optimizing production efficiency.

Sustainability in fabrication involves more than just technology. Engaging with local communities and ensuring fair labor practices are integral. As more companies seek to go green, transparency will become an essential part of the supply chain.