A Brief Discussion on the Pouring of Precision Casting Equipment in Dalian Precision Casting Factory

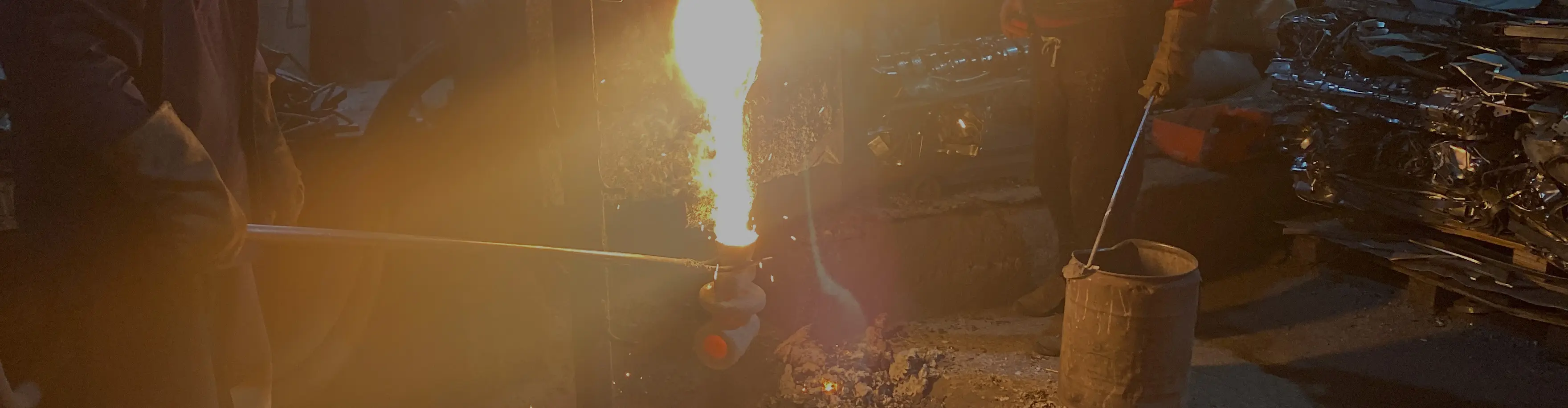

Dalian Precision Casting Factory has many professional technical methods for precision casting equipment. Today, the editor of precision casting equipment will introduce the pouring process of precision casting equipment to you.

The pouring process of lost foam casting is significantly different from that of traditional casting. During traditional casting and pouring, the metal liquid close to the sand mold will melt again shortly after quenching, and the cooling intensity of the sand mold tends to be gentle; In lost foam casting, due to the negative pressure, the liquid metal is constantly cooled during and after pouring. The temperature difference between the metal liquid that enters the sand mold first and the metal liquid that enters the sand mold last is large, and the slower the pouring speed, the greater the difference. This will affect the cooling shrinkage of the casting, and in severe cases, change the geometric dimensions of the casting, especially for plate and rod shaped castings.

Improving the filling speed of Dalian Precision Casting Factory is one of the ways to reduce temperature differences, but lost foam casting requires sufficient investment time. If the filling time is too fast, it will result in poor exhaust, leading to problems such as backflow or box collapse. Therefore, it is necessary to comprehensively analyze the problems that arise with castings, accumulate experience in practice, and develop reasonable pouring processes.

Considering the factors that affect the size changes of castings, a low pouring temperature is beneficial as it can reduce the temperature difference. Generally speaking, the geometric dimensions of castings in Dalian Precision Casting Factory are rarely related to the pouring temperature.