Functions of Investment Casting

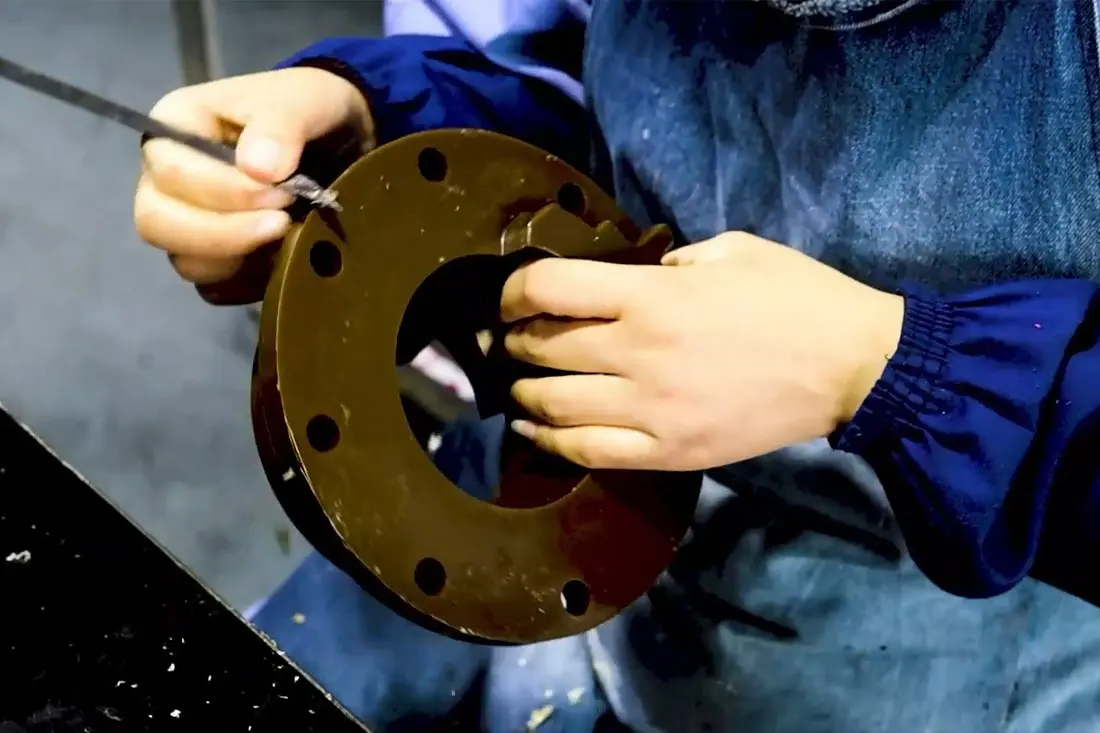

Investment casting is a precision casting process known for its ability to produce high-quality, complex components. Its key functions include:

1. Manufacturing Complex Castings

Investment casting allows for the production of intricate shapes with high precision, including curves, patterns, and internal cavities. This method ensures dimensional accuracy and is ideal for components requiring fine details, such as automobile engine cylinders and aircraft turbine blades.

2. Enhancing Casting Quality

Compared to traditional casting methods, investment casting minimizes defects like pores, slag inclusions, and stress concentrations, improving thermal fatigue resistance. The use of smooth metal molds reduces surface imperfections, resulting in better surface quality and fewer post-processing requirements.

3. Improving Casting Performance

Investment casting operates at relatively low process temperatures, reducing metal-mold interactions. This helps prevent oxidation and material degradation, enhancing the mechanical strength, durability, and corrosion resistance of the final product.

With its precision, superior surface finish, and ability to produce complex geometries, investment casting remains a preferred choice in industries such as aerospace, automotive parts,valve parts and medical manufacturing.