Lantian Precision Casting Factory--Polishing details with craftsmanship, defining precision with technology.

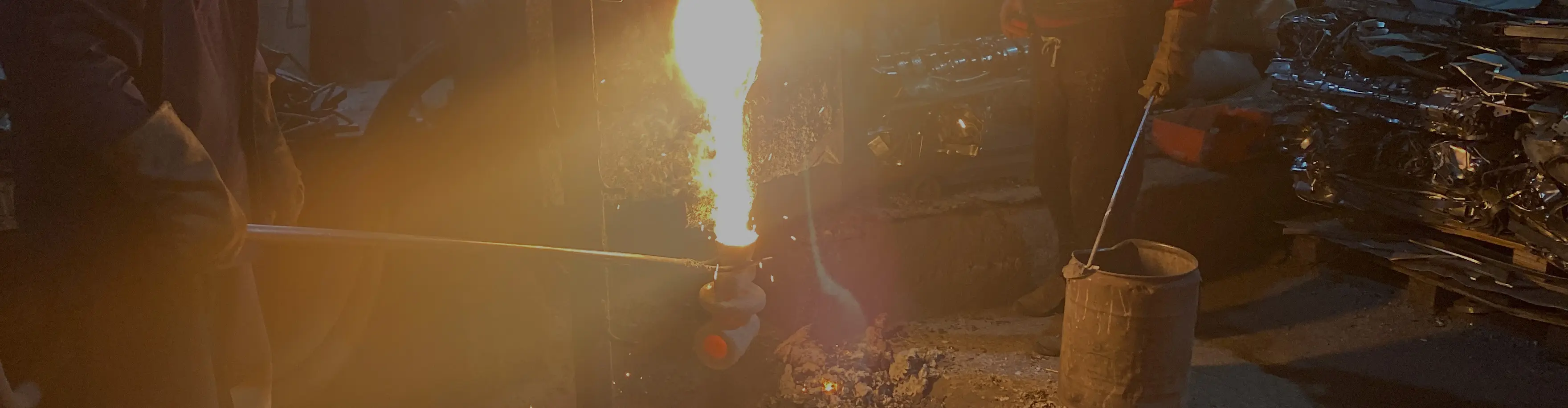

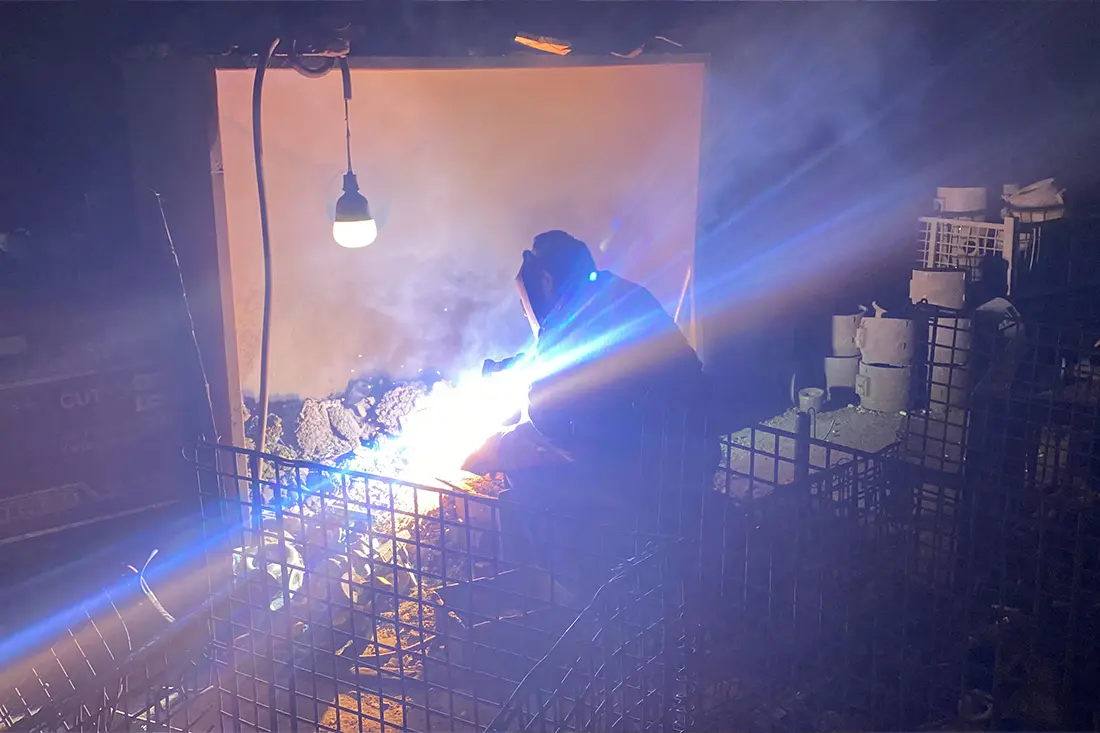

Stainless steel lost wax casting (investment casting) is a high-end technology of pouring metal liquid after wax molding and dewaxing at high temperature, which is widely used in aerospace, medical equipment, automotive parts and other fields with strict requirements on precision and performance. The core process includes the following key links:

Custom Precision Molds for High-Quality Metal Casting Products: Enhance Your Production Efficiency

In the competitive world of metal casting, precision and durability are non-negotiable. At Densen Group, we specialize in designing and manufacturing custom metal casting molds tailored to meet the exact specifications of your production needs. Whether you’re crafting automotive components, industrial machinery parts, or intricate decorative elements, our molds ensure flawless replication and consistent quality.

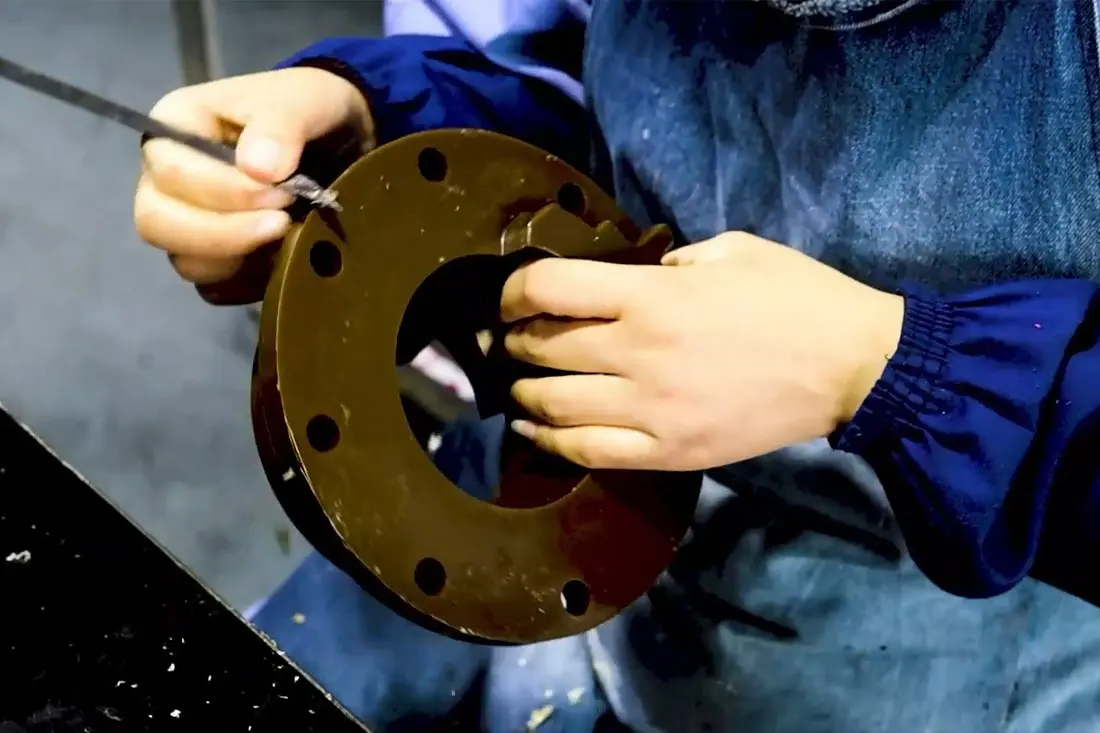

Precision Quality Control for OEM Metal Parts: Your Ultimate Guide to QC Process Charts

In the high-stakes world of precision metal components, a 0.01mm deviation can mean catastrophic failure. Our QC Process Chart System delivers 12 critical control points and 3-layer quality defense mechanisms to ensure flawless production from raw materials to final inspection.

Revolutionizing Precision Agriculture: How Lost Wax Casting Enhances Farm Machinery Efficiency

In the evolving landscape of agricultural innovation, lost wax casting—a centuries-old technique—has emerged as a game-changer for modern farming equipment. By combining ancient craftsmanship with cutting-edge engineering, this method is reshaping the durability, precision, and sustainability of agricultural machinery, driving efficiency gains across the sector.

Precision Engineering Excellence: How Densen Group Revolutionizes Mechanical Manufacturing

In the fast-evolving landscape of mechanical engineering, Densen Group stands at the forefront of innovation, combining cutting-edge technology with decades of expertise to deliver unparalleled precision in CNC machining, custom part fabrication, and industrial component manufacturing. As a leader in high-performance mechanical solutions, we pride ourselves on transforming complex engineering challenges into tangible results for clients across aerospace, automotive, energy, and electronics sectors.

Future Prospects of Investment Casting: Trends, Challenges, and Opportunities

Investment casting, a precision manufacturing method rooted in ancient techniques, continues to evolve as industries demand components with higher complexity, durability, and cost-efficiency. As global manufacturing shifts toward automation, sustainability, and advanced materials, investment casting is poised to adapt and thrive. Here’s an in-depth look at its future trajectory:

Sodium Silicate Investment Casting Process

Sodium silicate investment casting, also known as water glass casting, is a cost-effective precision casting method widely used for steel and alloy components in industries such as automotive, construction, and machinery.

Mastering Lost-Wax Casting: A Precision Manufacturing Process for Modern Industries

Lost-wax casting, also known as investment casting, is a time-tested metal fabrication technique that has evolved into a cornerstone of modern precision manufacturing. Renowned for its ability to produce intricate, complex geometries with exceptional accuracy, this process is widely used across industries—from aerospace and healthcare to jewelry and automotive engineering. In this article, we delve into the science, applications, and advantages of lost-wax casting, revealing why it remains a preferred choice for high-performance alloy production and custom metal parts.

Investment Casting Process: A Comprehensive Guide

1. Introduction to Investment Casting

Investment casting, also known as lost-wax casting, is a manufacturing process used to produce intricate and high-precision metal casting components. The process dates back over 5,000 years, with early applications found in ancient Egypt and China. Today, it is widely used in industries such as aerospace, automotive, medical, and industrial machinery due to its ability to produce complex geometries with excellent surface finishes.

Design of Investment Casting Process

Investment casting, also known as “lost wax casting”, usually in the wax mold surface coated with several layers of refractory materials, to be hardened and dried after the wax mold melted away and made of shell, and then after baking, and then pouring, and obtain castings of a method, due to the casting has a high degree of dimensional accuracy and surface finish, so it is also known as “melting precision casting”.

What Is Silica Sol Precision Casting? Why Can Silica Sol Be Used For Precision Casting?

Silica sol (colloidal silica), also known as silicic acid solution, is a colloidal dispersion of amorphous silica aggregate particles in water. Silica sol has a wide range of water loss temperature, which not only destroys its bonding strength, but also makes its three-dimensional structure more stable, resulting in higher bonding strength. It is a good inorganic binder for precision casting.

Functions of Investment Casting

Investment casting is a precision casting process known for its ability to produce high-quality, complex components. Its key functions include