Revolutionizing Precision Agriculture: How Lost Wax Casting Enhances Farm Machinery Efficiency

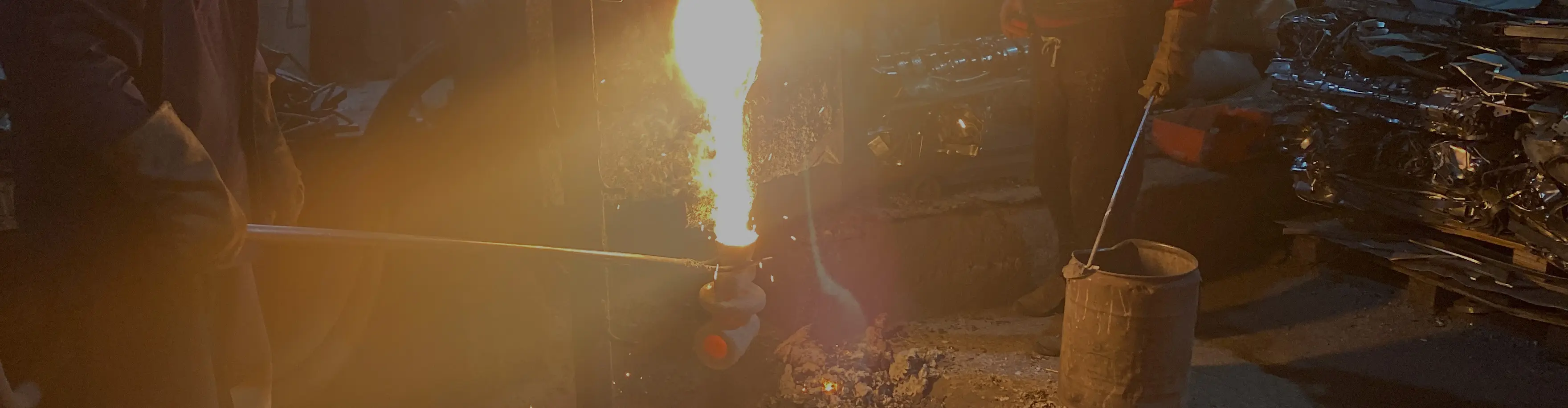

Introduction

In the evolving landscape of agricultural innovation, lost wax casting—a centuries-old technique—has emerged as a game-changer for modern farming equipment. By combining ancient craftsmanship with cutting-edge engineering, this method is reshaping the durability, precision, and sustainability of agricultural machinery, driving efficiency gains across the sector.

Case Study: Lightweight Suspension Components

Agricultural machinery manufacturer adopted precision casting to redesign welding-based suspension parts into integrated cast components. Using topology optimization and 3D-printed wax molds, the new design reduced weight by 8% while enhancing durability by 2.5 times. This innovation not only lowers production costs but also allows farmers to attach heavier implements without exceeding axle load limits, improving versatility in tasks like soil tilling and crop harvesting.

Applications in Precision Farming Tools

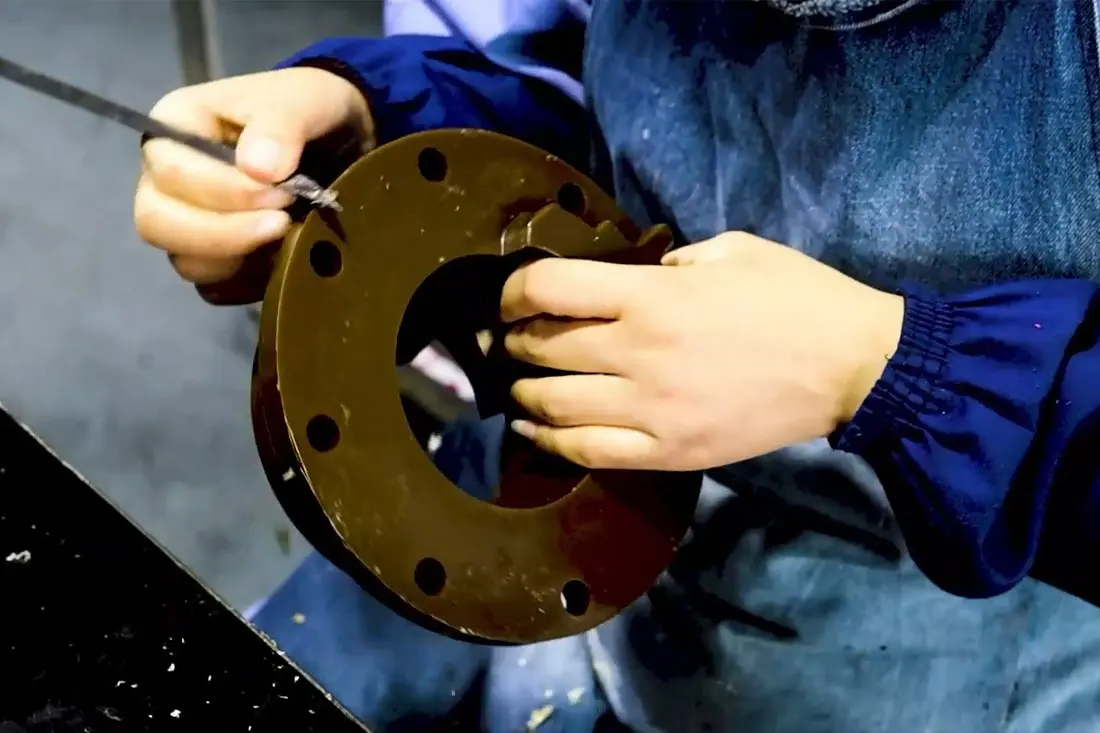

- Automated Wax Injection Systems: Companies have developed automated wax injection machines for high-precision agricultural parts, minimizing human error and ensuring consistent quality.

- Durable Irrigation Components: Lost wax casting produces corrosion-resistant fittings and valves for drip irrigation systems, critical for water-efficient farming practices.

- Livestock Equipment: Precision-cast components for feeding troughs and milking systems reduce wear and tear, extending service life in harsh environments.

Sustainability Advantages

- Material Efficiency: Near-net-shape casting minimizes waste, aligning with eco-friendly farming goals.

- Energy Savings: Optimized designs reduce fuel consumption in machinery, supporting carbon footprint reduction.

- Circular Economy: Recyclable wax materials and reusable molds lower production costs and environmental impact.

Future Outlook

As agriculture embraces smart technologies, investment casting is poised to integrate with AI-driven design tools and additive manufacturing. For instance, hybrid 3D-printed wax molds could enable rapid prototyping of custom farm tools, tailored to specific crop needs or regional terrains.

Conclusion

By merging heritage techniques with modern engineering, lost wax casting is not just preserving craftsmanship but also propelling agriculture into a new era of precision and sustainability. As farmers seek smarter solutions, this ancient method will remain pivotal in meeting the demands of 21st-century food production.