What is Silica Sol Investment Casting?

Silica sand casting, particularly when using silica sol as a binder, is a specialized form of investment casting that offers several distinct advantages for certain types of metal castings. Here's a summary of the key points you've mentioned:

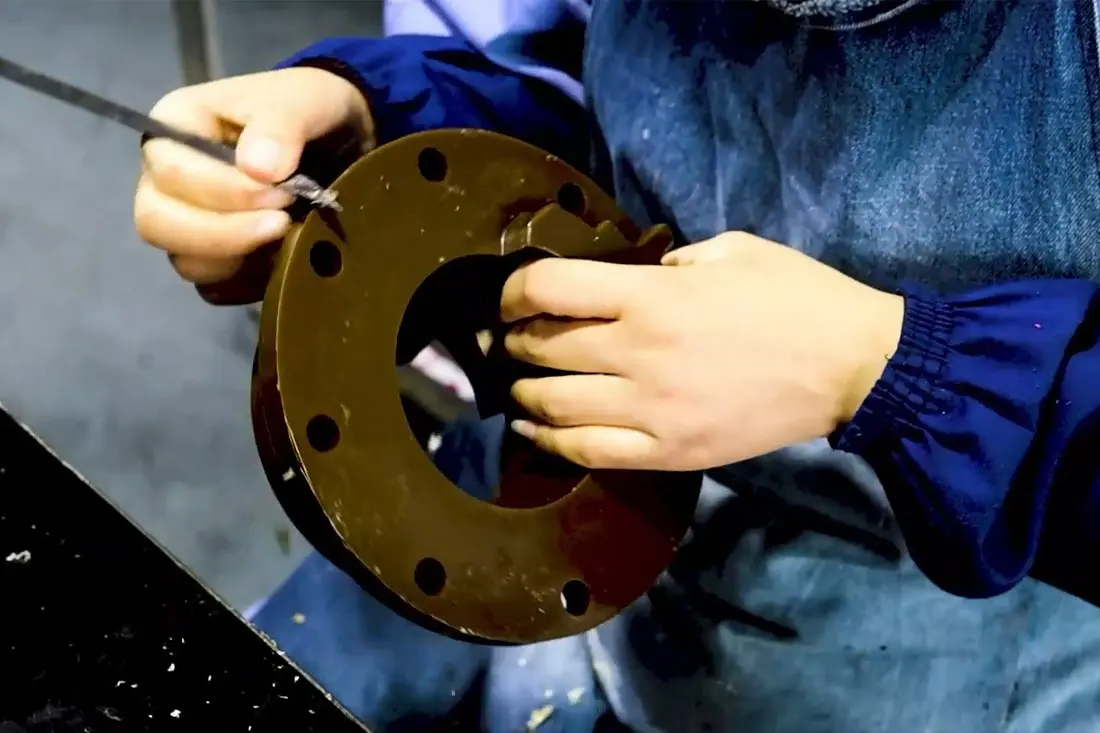

1. High Precision and Surface Finish: Silica sand casting is known for producing castings with a fine surface and high accuracy. The dimensional tolerance can reach up to CT4 - CT6, which is suitable for applications requiring precision.

2.Material Suitability: This process is particularly adept at handling stainless steel and alloy steel castings, which are common in industries that require high corrosion resistance and strength.

3. Quality and Cost: While silica sol casting is more expensive than water glass casting, typically costing about twice as much, it delivers superior size and surface quality. This makes it a preferred choice when high-quality castings are paramount.

4. Temperature Resistance: The use of silica sand as a moulding material allows for high temperature resistance, capable of withstanding up to 2000 degrees Celsius. This is beneficial for casting metals with high melting points.

5. Surface and Internal Quality: Castings produced through silica sand casting have very few surface and internal defects, which is crucial for applications where reliability and longevity are key.

6. Comprehensive Services: Companies like Densen, which you've mentioned, offer a full range of services from custom pattern design to finished castings, including secondary operations such as CNC machining, heat treatment, and surface treatment. This service is valuable for customers who require a complete solution from a single source.

7. International Quality Standards: Densen's capability to meet international quality standards is important for global customers who need assurance that the products they receive will adhere to recognized benchmarks.

8. Customization and Flexibility: The mention of custom pattern design indicates a high level of customization, which is essential for unique or complex casting requirements.

In summary, silica sol casting is a high-quality casting process that, despite its higher cost, offers significant benefits in terms of precision, surface finish, and material properties. It is particularly suitable for applications where these factors are critical to the performance and longevity of the castings. Companies like Densen that offer silica sol casting services provide a comprehensive solution for customers looking for high-quality castings that meet international standards.